Motorcycle die-casting-type transmission case shell

A technology for transmission boxes and motorcycles, applied in transmission boxes, components with teeth, etc., can solve the problems of complicated processing, large specific gravity, low precision, etc., and achieve the effects of simple processing, light weight and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

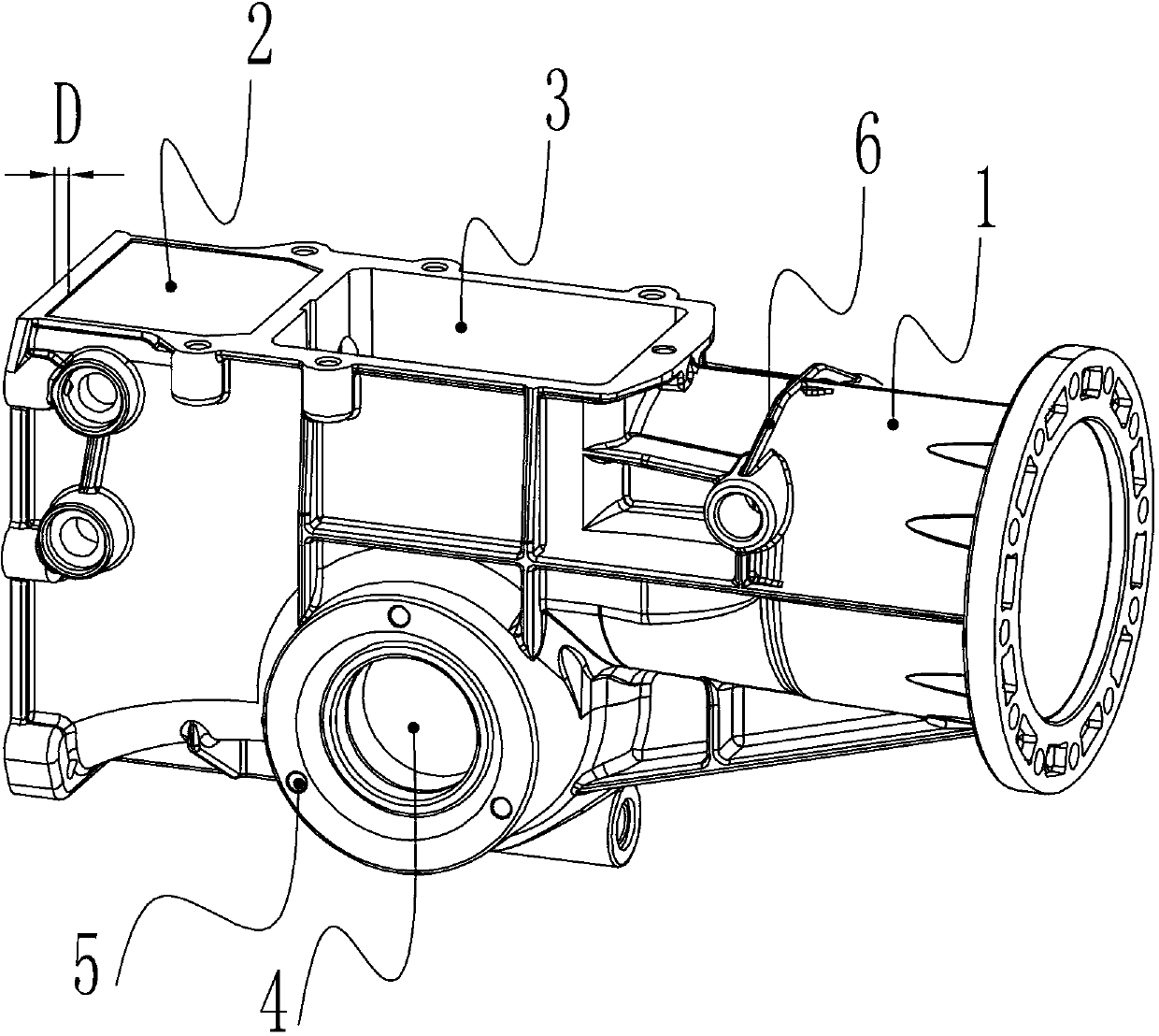

[0010] Such as figure 1 Shown: motorcycle die-cast transmission case housing, including aluminum alloy housing 1, housing 1 is provided with air window 3, air outlet 2, parts installation hole 4, fastener installation hole 5, housing 1 The wall thickness is D, and D is 3.5mm. The outer surface of the shell 1 is provided with reinforcing ribs 6. The reinforcing ribs 6 have a mesh structure and are distributed in the air window 3, the air outlet 2, the component mounting holes 4, and the fastener mounting holes. 5, the fastener installation hole 5 and the housing 1 are integral die-casting parts.

[0011] In this embodiment, because the transmission box adopts the die-casting manufacturing process, and the transmission box housing 1 is made of aluminum alloy material, and the wall thickness of the housing 1 is D, and D is 3.5mm, compared with the housing of the existing die-casting process It is thinner, which reduces the quality of the transmission box housing 1 and reduces th...

Embodiment 2

[0013] Such as figure 1 Shown: motorcycle die-cast transmission case housing, including aluminum alloy housing 1, housing 1 is provided with air window 3, air outlet 2, parts installation hole 4, fastener installation hole 5, housing 1 The wall thickness is D, and D is 4mm. The outer surface of the shell 1 is provided with reinforcing ribs 6. The reinforcing ribs 6 have a mesh structure and are distributed in the air window 3, the air outlet 2, the component mounting hole 4, and the fastener mounting hole 5. Around, the fastener installation hole 5 and the housing 1 are integral die-casting parts.

[0014] In this embodiment, because the transmission box adopts the process of die-casting manufacturing, and the transmission box housing 1 is made of aluminum alloy material, and the wall thickness of the housing 1 is D, and D is 4mm, compared with the housing of the existing die-casting process thinner, which reduces the quality of the transmission box housing 1 and reduces the ...

Embodiment 3

[0016] Such as figure 1 Shown: motorcycle die-cast transmission case housing, including aluminum alloy housing 1, housing 1 is provided with air window 3, air outlet 2, parts installation hole 4, fastener installation hole 5, housing 1 The wall thickness is D, and D is 5mm. The outer surface of the shell 1 is provided with reinforcing ribs 6. The reinforcing ribs 6 have a mesh structure and are distributed in the air window 3, the air outlet 2, the component mounting hole 4, and the fastener mounting hole 5. Around, the fastener installation hole 5 and the housing 1 are integral die-casting parts.

[0017] In this embodiment, because the transmission box adopts the process of die-casting manufacturing, and the transmission box housing 1 is made of aluminum alloy material, and the wall thickness of the housing 1 is D, and D is 5mm, compared with the housing of the existing die-casting process thinner, which reduces the quality of the transmission box housing 1 and reduces the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com