Flywheel energy storage rotor shaft

A flywheel energy storage and rotor shaft technology, which is applied in the direction of controlling mechanical energy, electrical components, electromechanical devices, etc., can solve the problems of motor rotor imbalance, rotor forced vibration, etc., and achieve the effect of smooth operation, vibration reduction and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

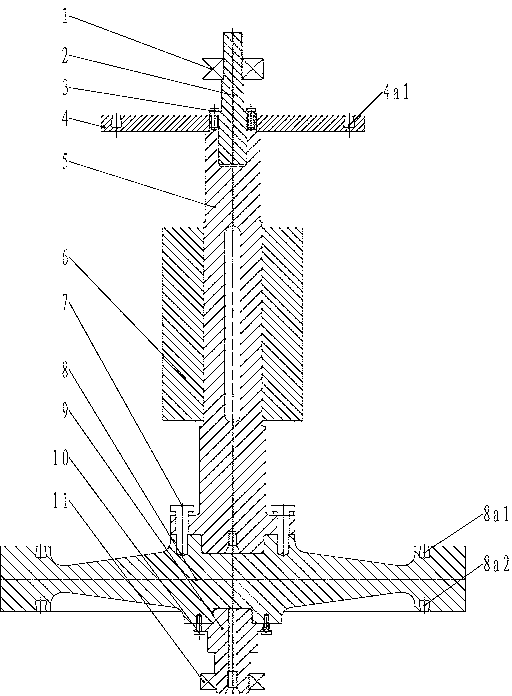

[0011] Such as figure 1 As shown, the present invention consists of an upper bearing 1, a non-magnetic shaft 2, a motor rotor mandrel 5, a motor rotor 6, a flywheel 8, a lower end shaft 9 and a lower bearing 11, and a dynamic balancing process is installed on the upper end of the motor rotor mandrel 5 Disk 4. The entire flywheel rotor shaft adopts a vertical structure. The flywheel rotor shaft is supported on the upper bearing 1 and the lower bearing 11. The connecting bolt 3 connects the non-magnetic shaft 2 and the motor rotor core shaft 5, and the motor rotor 6 is sleeved on the motor rotor core shaft 5, and the torque is transmitted by the key. The flywheel connecting bolt 7 connects the flywheel 8 and the motor rotor core shaft 5 . The lower end shaft 9 is connected with the flywheel 8 through the lower end shaft connecting bolt 10 .

[0012] The dynamic balancing process plate 4 is a plate structure, and its upper part is processed with an annular dovetail groove 4a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com