Light-sensitive resin composition, a dry film solder resist and a circuit substrate

A technology of photosensitive resin and composition, applied in secondary processing of printed circuits, photosensitive materials for opto-mechanical equipment, optics, etc. The effect of excellent cross-linked structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

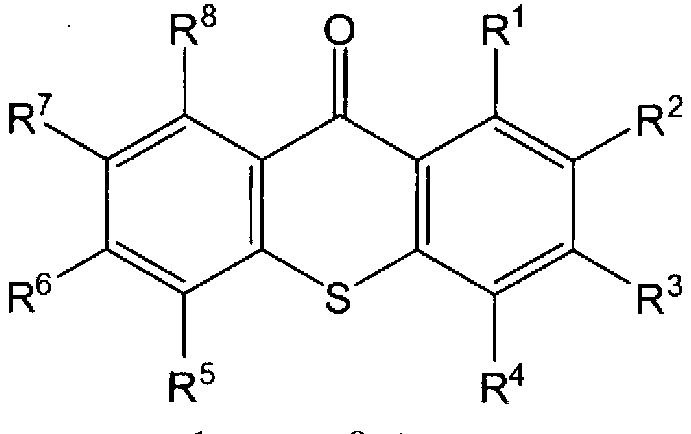

Method used

Image

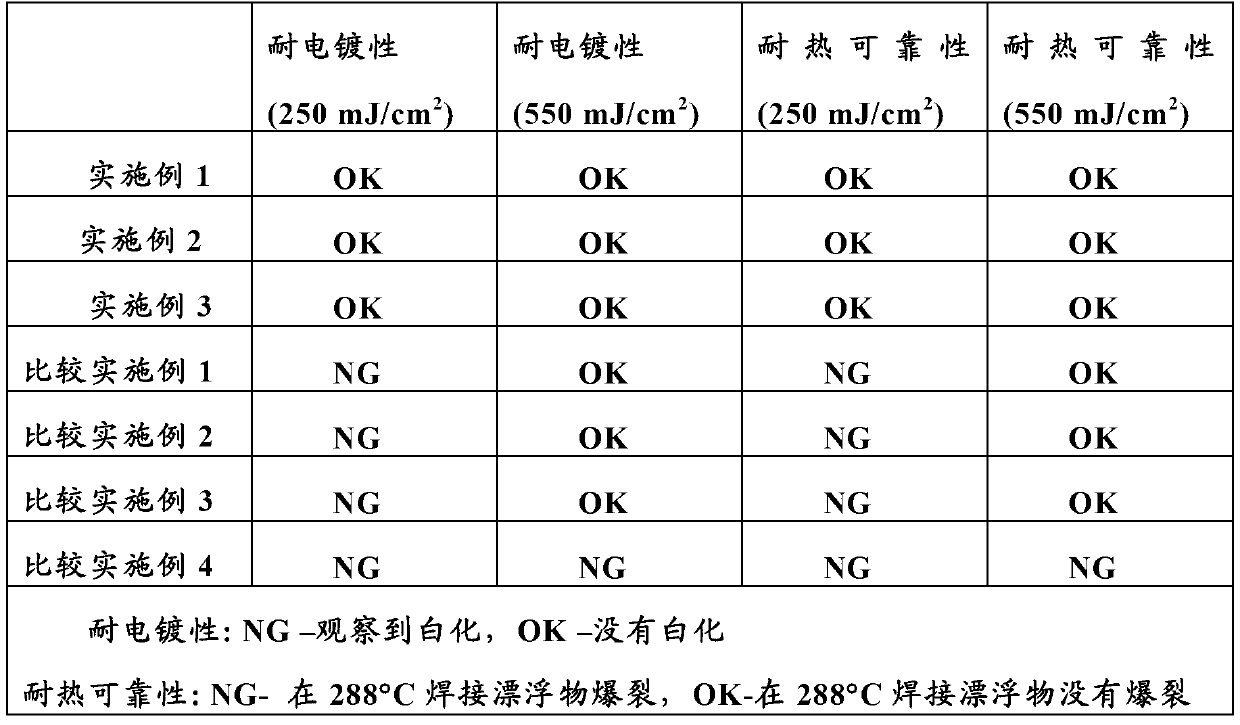

Examples

Embodiment 1

[0132] (1) Preparation of photosensitive resin composition

[0133] Mix 40% by weight of CCR-1235 from Nippon Kayaku, Co., Ltd. as an acid-modified oligomer, 10% by weight of DPEA-12 from Kayarad as a photopolymerizable monomer, 4% by weight of TPO As a photoinitiator, 1% by weight of ITX (a mixture of 2-isopropylthioxanthone and 4-isopropylthioxanthone at a molar ratio of 1:1), 15% by weight of ITX from Nippon Kayaku Co., Ltd. .The EOCN-1020 as epoxy resin, 0.1% by weight of dicyandiamide as epoxy curing agent, 0.1% by weight of 2MI as epoxy catalyst, 15% by weight of BaSO 4 As filler, 0.2% by weight of Pigment Blue 15:3 and 0.2% by weight of Pigment Yellow 151 as pigment, 0.3% by weight of BYK-380N as leveling agent, 0.1% by weight of Disperbyk-110 as dispersant, and 14% by weight DMF as a solvent to provide a photosensitive resin composition.

[0134] (2) Preparation of dry film

[0135] The photosensitive resin composition prepared as above was applied to a PET film as ...

Embodiment 2

[0140] Prepare the photosensitive resin composition with the same method as described in the previous example 1, the difference is to use 4% by weight of I651 as a photoinitiator and use 1% by weight of ITX, and then use the same method as described in the previous example 1 Printed circuit boards were prepared in the same manner.

Embodiment 3

[0142] A photosensitive resin composition was prepared in the same manner as described in the previous example 1, except that 3.5% by weight of TPO was used as a photoinitiator and 1.5% by weight of ITX was used, and then as described in the previous example 1 Printed circuit boards were prepared in the same manner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com