Intelligent diamond cutter capable of sensing cutting state without any wire

A diamond tool and wireless sensing technology, applied in the field of intelligent diamond tools, can solve the problems of inability to meet the requirements of ultra-precision machining monitoring and measurement accuracy and sensitivity, destroying the performance of ultra-precision equipment, and complex monitoring means, achieving low cost and comprehensive functions. Powerful, accurate and sensitive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner, but the protection scope of the present invention is not limited to the following embodiments.

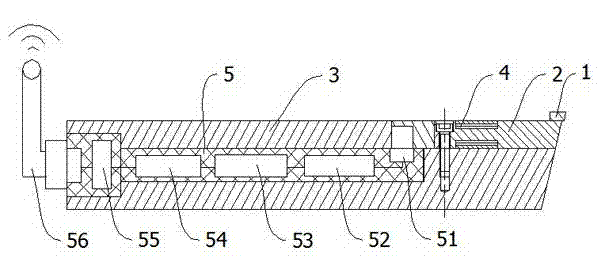

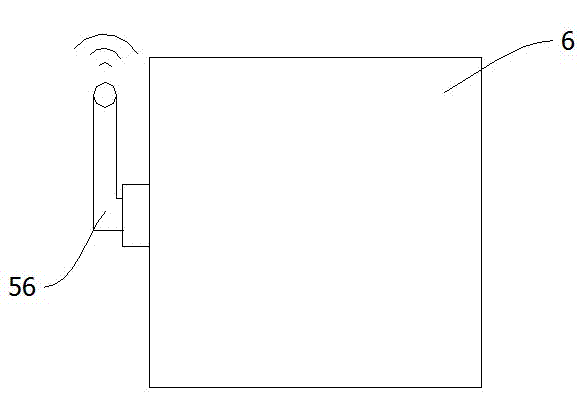

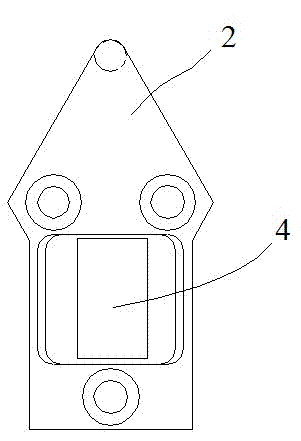

[0019] like figure 1 As shown, a smart diamond tool for wirelessly sensing cutting states involved in this embodiment includes: a diamond blade 1, a smart diamond blade 2, a tool bar 3, a sensor system 4 and a sensing signal processing system 5, the smart diamond blade 2 is fixed on the front part of the cutter bar 3, the upper end of the front part of the intelligent diamond blade 2 is fixed with a diamond blade 1, the sensor system 4 is arranged in the intelligent diamond blade 2, and the sensing signal processing system 5 is arranged in the cutter bar 3.

[0020] like figure 1 As shown, the perceptual signal proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com