Micro-foaming injection structure

A technology of micro-foaming and micro-cellular foaming, which is applied in the field of injection structure with micro-cellular foaming function, can solve the problems of complex hydraulic control circuit of the control system, narrow market promotion area, high cost, etc., and achieve simple and effective structure, Dimensional stability and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

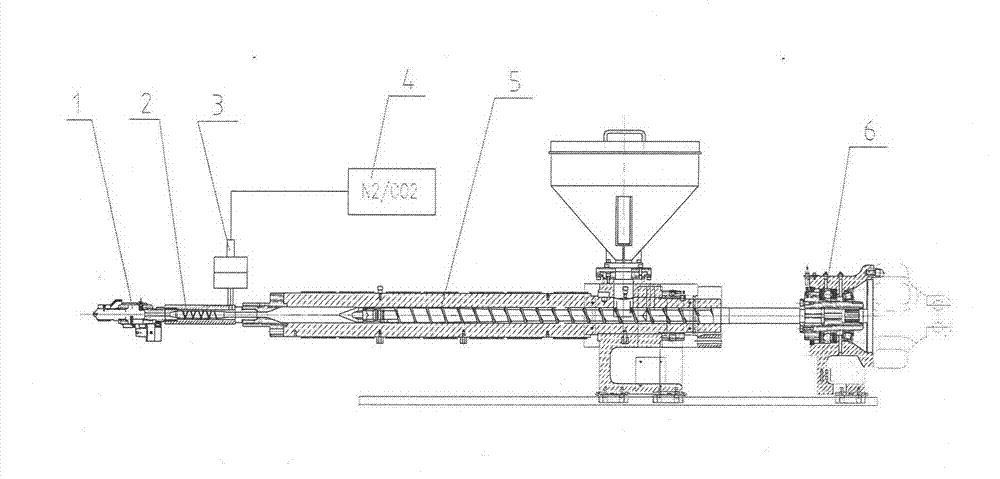

[0013] As shown in the figure, a micro-foaming injection structure includes a rapid nozzle (1), a mixer (2), an inflator (3), a supercritical fluid generator (4), a material tube group (5), And injection part (6), it is characterized in that: add mixer (2), pumping device (3) and rapid nozzle (1) at the front end of common injection molding machine barrel group; , the injection platform advances, and then the rapid nozzle (1) is in a closed and sealed state.

[0014] At this time, the injection molding machine starts to melt the glue, the pumping device (3) is opened, and the supercritical fluid generating device (4) injects the supercritical fluid into the mixer (2) and the material tube group (5), and the injection of the supercritical fluid The ratio and speed are closed-loop controlled by the computer of the injection molding machine. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com