Powdered coal pressure dense-phase conveying device and method of dry coal dust pressure gasification

A technology of pressurized gasification and dense phase transportation, which is applied in the direction of granular/powdered fuel gasification and joint combustion mitigation, etc. It can solve the problems of poor sealing and difficulty in accurately controlling the feed flow, so as to increase the nitrogen content and achieve uniformity Distribution and stability, effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

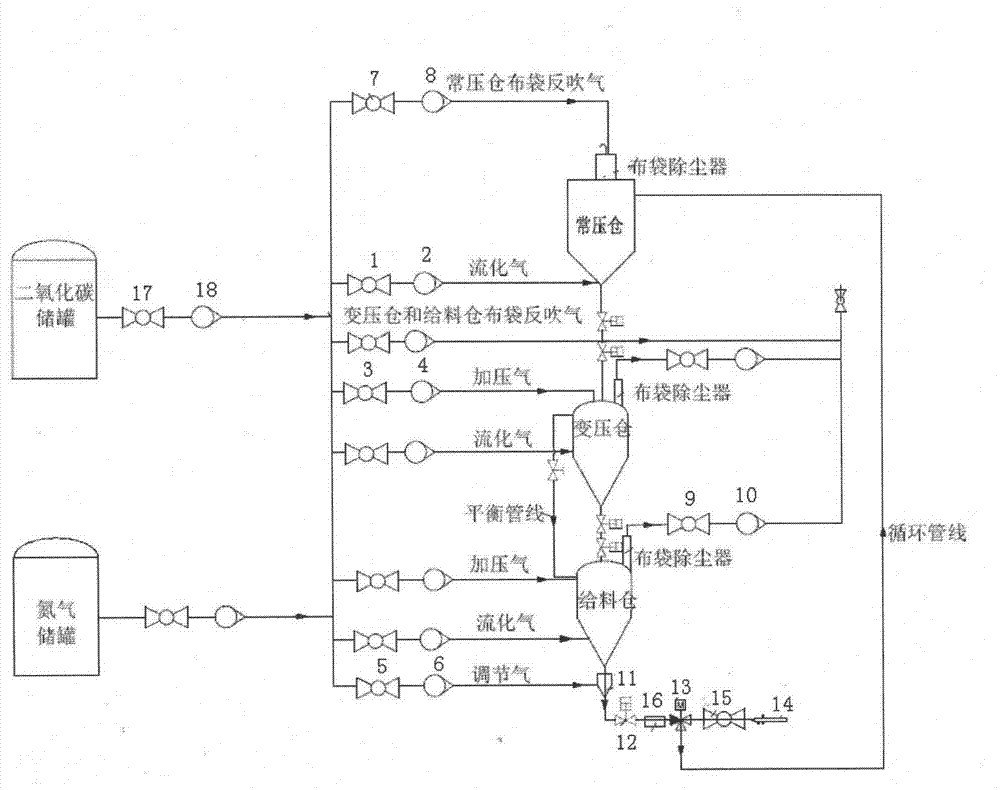

[0030] Such as figure 1As shown, the present invention provides a pulverized coal pressurized dense phase conveying device for pressurized gasification of dry coal powder, which includes a normal pressure bin, a variable pressure bin and a feeding bin arranged in sequence from top to bottom. The fluidizing gas inlets of the normal pressure bin, the variable pressure bin and the feeding bin are respectively connected to the gas distribution main pipe through their respective fluidizing gas pipelines, and the pressurized gas inlets of the pressure changing bin and the feeding bin are respectively connected through their respective pressurized gas pipelines Connect the gas distribution header. A fluidizing gas control valve 1 and a fluidizing gas flow meter 2 are provided on each fluidizing gas pipeline; a pressurized gas control va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com