Safety pants impregnator with generality

A technology of safety pants and dipping machine, which is used in liquid/gas/vapor finished product processing, textile material processing equipment configuration, etc. Evaluation and other issues, to achieve the effects of good stability and high performance, simple structure, convenient manufacturing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

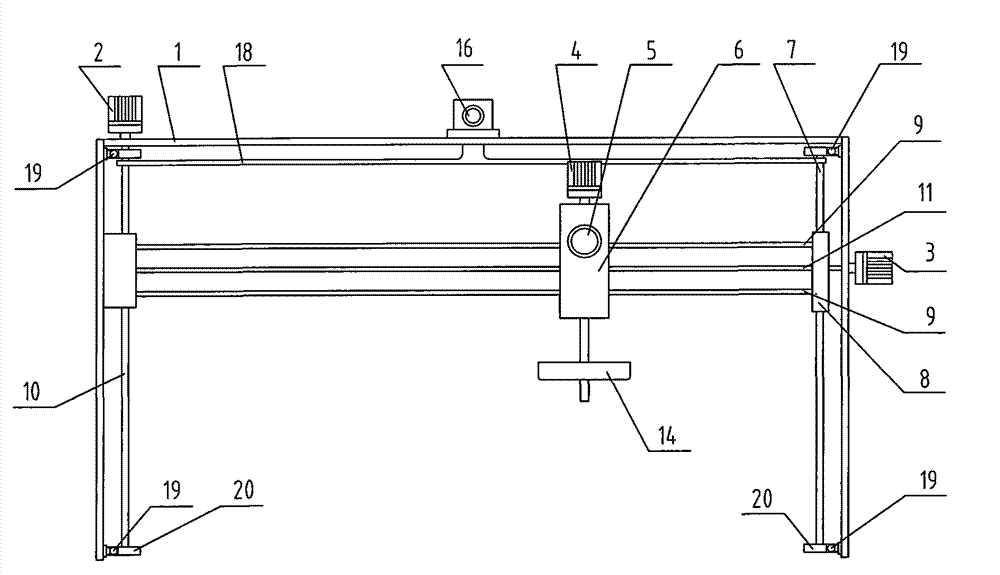

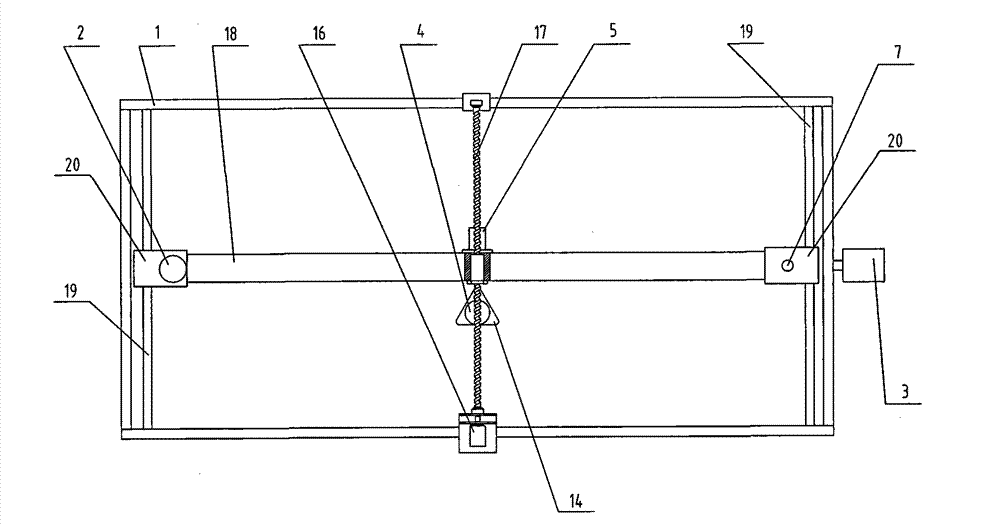

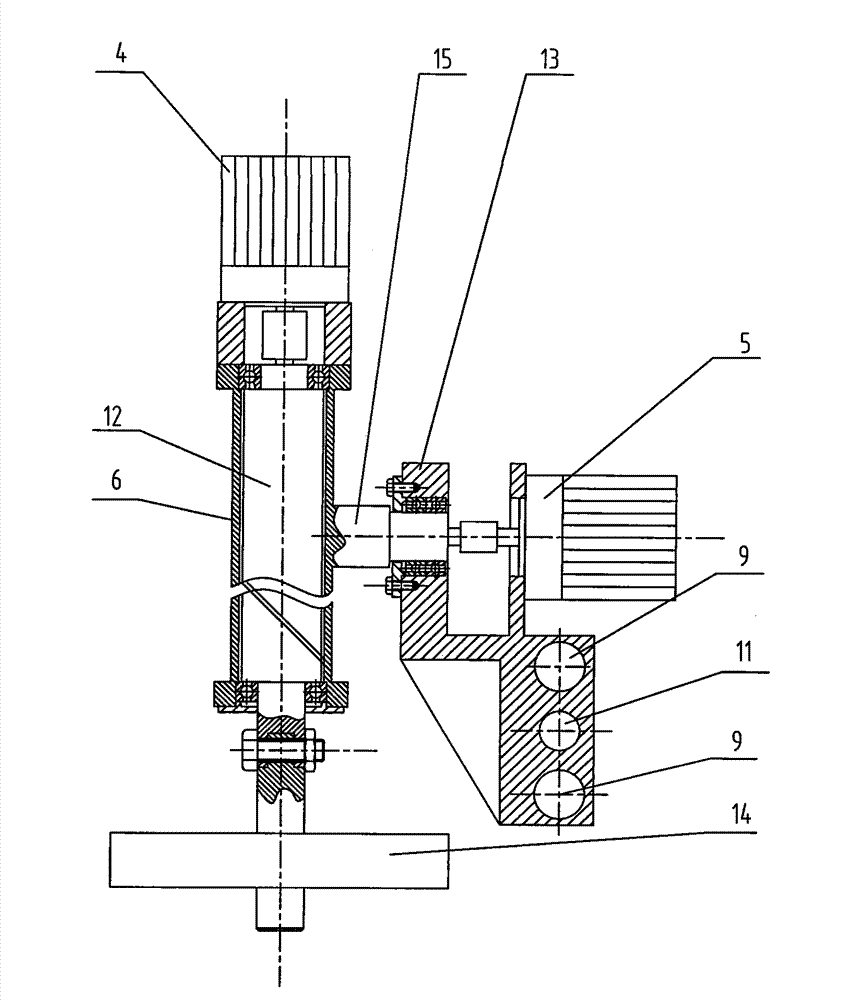

[0020] Specific embodiments: a universal dipping machine for safety pants, which includes a frame 1, a lifting motor 2, a left and right motor 3, a rotating motor 4, an inclination motor 5, a sleeve 6, a lifting guide rail 7, a lifting slider 8, Left and right guide rails 9, lifting ball screw pair 10, left and right ball screw 11, rotating shaft 12, support body 13, mold 14, front and rear motors 16, front and rear ball screw pairs 17 and front and rear transmission beams 18, lifting ball screw pair 10 Placed vertically parallel to the lifting guide rail 7, four front and rear guide rails 19 parallel to each other are fixed on the frame 1, and each front and rear guide rail 19 is equipped with a connecting slider 20, and the lead screws of the lifting ball screw pair 10 are respectively Rotately connected with a pair of up and down relative connecting sliders 20, the lifting guide rail 7 is respectively rotatably connected with another pair of up and down relative connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com