Free piston Stirling engine system utilizing high-low temperature heat sources meanwhile

A technology of Stirling engine and high-temperature heat source, which is applied in the direction of hot gas variable displacement engine device, machine/engine, mechanical equipment, etc., and can solve the problem of increasing friction loss between piston and cylinder, adverse effects of piston and cylinder seal, increasing Problems such as flow loss and cooling loss can be solved to achieve the effect of ensuring low cost, avoiding adverse effects, and ensuring compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

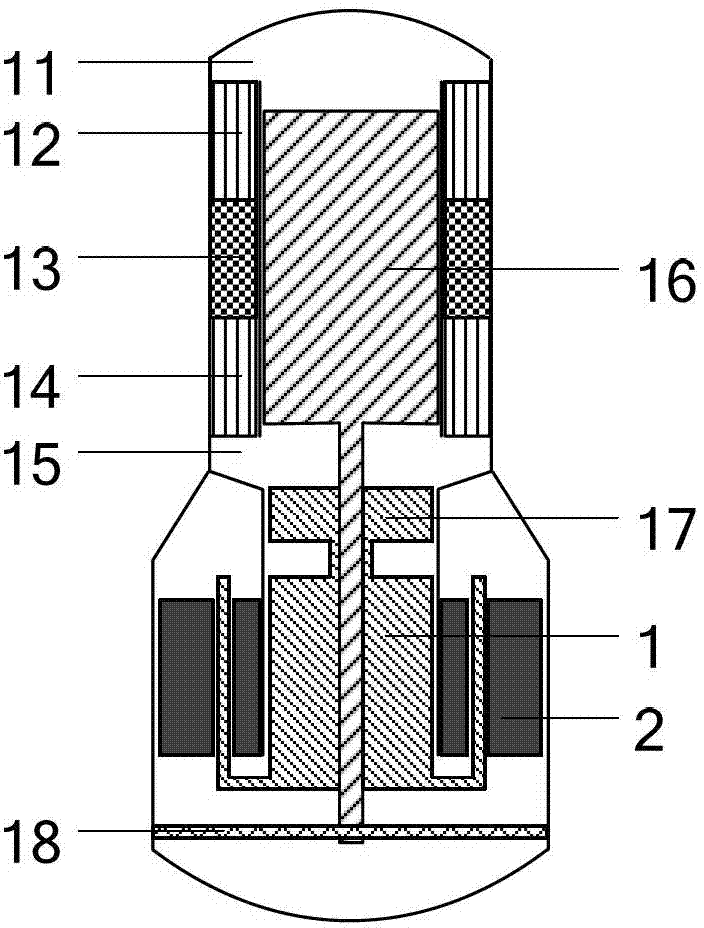

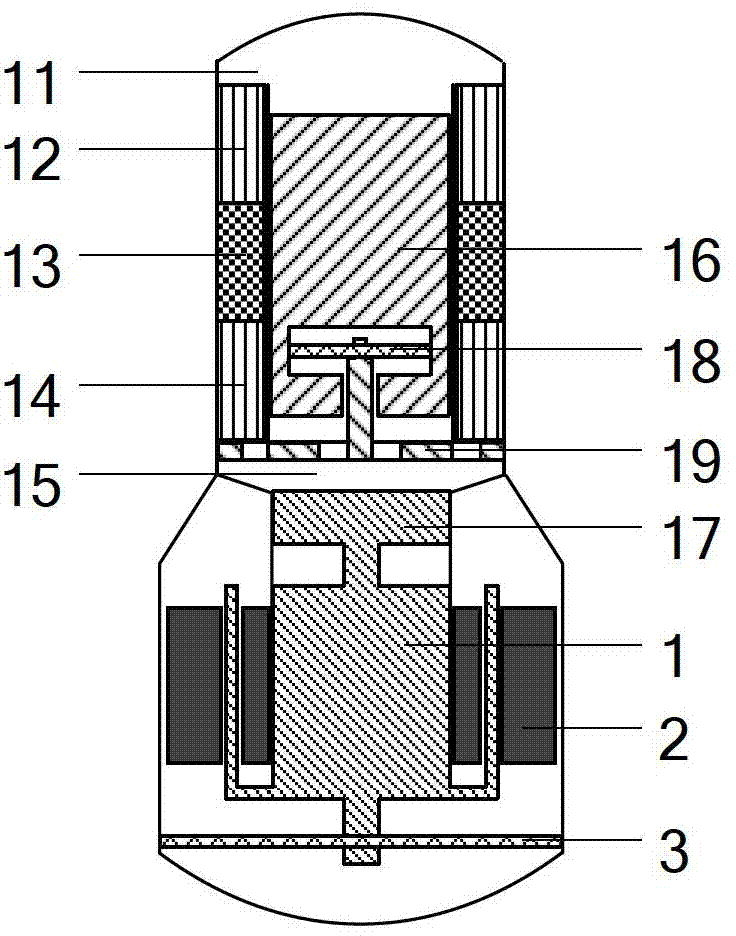

Image

Examples

Embodiment 2

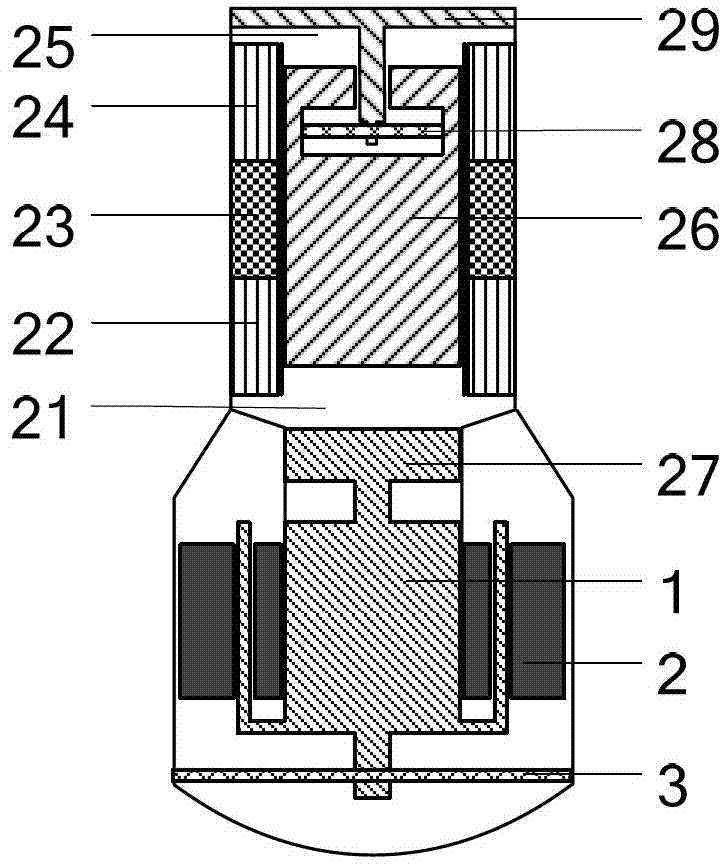

[0063] Figure 6 It is a structural schematic diagram of Embodiment 2 of the free-piston Stirling engine system utilizing both high and low temperature heat sources of the present invention. Such as Figure 6As shown, the high-temperature heat source free-piston Stirling engine and the low-temperature cold source free-piston Stirling engine are symmetrically arranged in a straight line, and the linear generator is perpendicular to the high-temperature heat source free-piston Stirling engine and the low-temperature cold source free-piston Stirling engine Arrangement, the three are connected by a three-way pipe, the high-temperature heat source is connected to the first expansion chamber 15 of the piston Stirling engine, and the low-temperature cold source is connected to the second expansion chamber 21 of the piston Stirling engine and the linear generator respectively The three branch pipes of the three-way pipe.

[0064] The structure of each component of the high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com