Electro-hydraulic servo actuator

An electro-hydraulic servo and actuator technology, which is applied to fluid pressure actuators, fluid pressure actuator system components, mechanical equipment, etc., can solve the problem of single working mode of electro-hydraulic actuators, failure to realize fault self-protection, and high energy consumption and other problems, to achieve the effect of simple structure, fast response speed and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

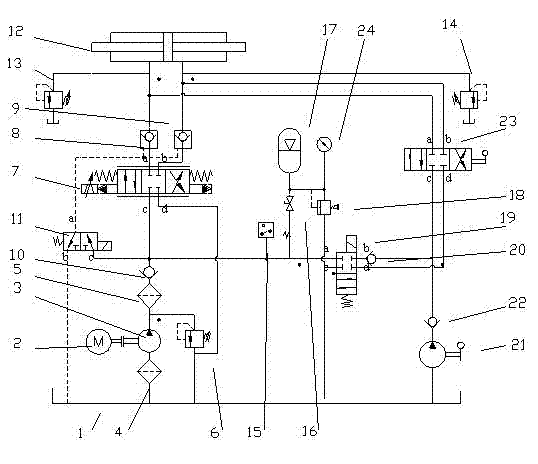

[0009] An electro-hydraulic servo actuator, including: fuel tank 1, motor 2, hydraulic pump 3, overflow valve 6, servo valve 7, hydraulic cylinder 12, pressure relay 15, accumulator 17, pressure gauge 24, and also includes: filter Device A4, filter B5, hydraulic lock A8, hydraulic lock B9, one-way valve A10, one-way valve B20, one-way valve C22, safety valve A13, safety valve B14, safety valve C18, two-position three-way solenoid valve 11, Two-position four-way solenoid valve 19, three-position four-way manual reversing valve 23, manual pump 21, and manual shut-off valve 16. The inlet of the hydraulic pump 3 is connected to the outlet pipeline of the filter A4, the outlet of the hydraulic pump 3 is connected to the inlet of the filter B5 and the inlet pipeline of the overflow valve 6, the inlet of the check valve A10 is connected to the outlet pipeline of the filter B5, and the one-way valve The outlet of A10 is respectively connected to the inlet c of servo valve 7 and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com