Split-type deep sea hydraulic valve box

A hydraulic valve, split-type technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of low work efficiency, difficult operation, large volume, size and weight of the valve block 103, and achieve improvement Work efficiency, easy operation, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

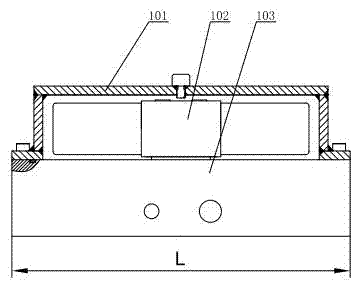

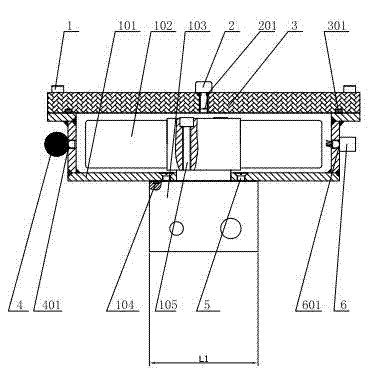

[0017] Such as figure 2 As shown, the present invention includes a box body 101, a solenoid valve 102 and a valve block 103. The box body 101 is an inner flange made of a metal material resistant to seawater corrosion. The solenoid valve 102 is placed in the box body 101, the valve block 103 and the solenoid valve 102 are fixed by the first hexagon socket head screw 105, the valve block 103 and the box body 101 are fixed by the countersunk head screw 5, and sealed by the fourth sealing ring 104 , the length of the valve block 103 is less than the length of the box body 101. The cover plate 3 and the box body 101 are fixedly connected through the second hexagonal screws 1 installed symmetrically, and form an installation cavity where the solenoid valve 102 can be installed. The connection between the box body 101 and the cover plate 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com