Torque transmission device for a motor vehicle

A technology for motor vehicles and equipment, applied to mechanical equipment, mechanically driven clutches, non-mechanically driven clutches, etc., can solve the problem that the clutch is difficult to achieve fine and gradual manipulation, and achieve the effect of making up for invalid strokes and eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

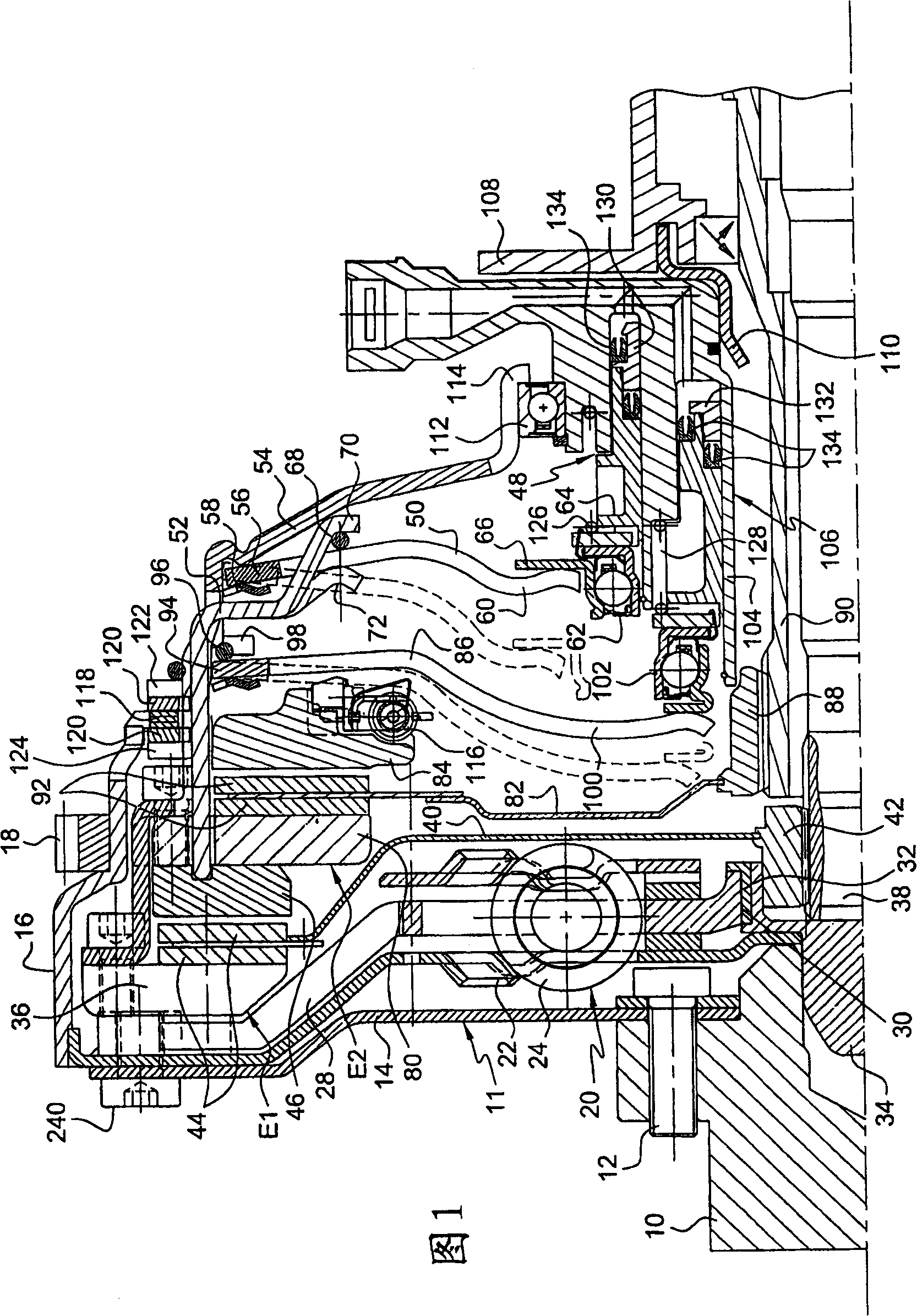

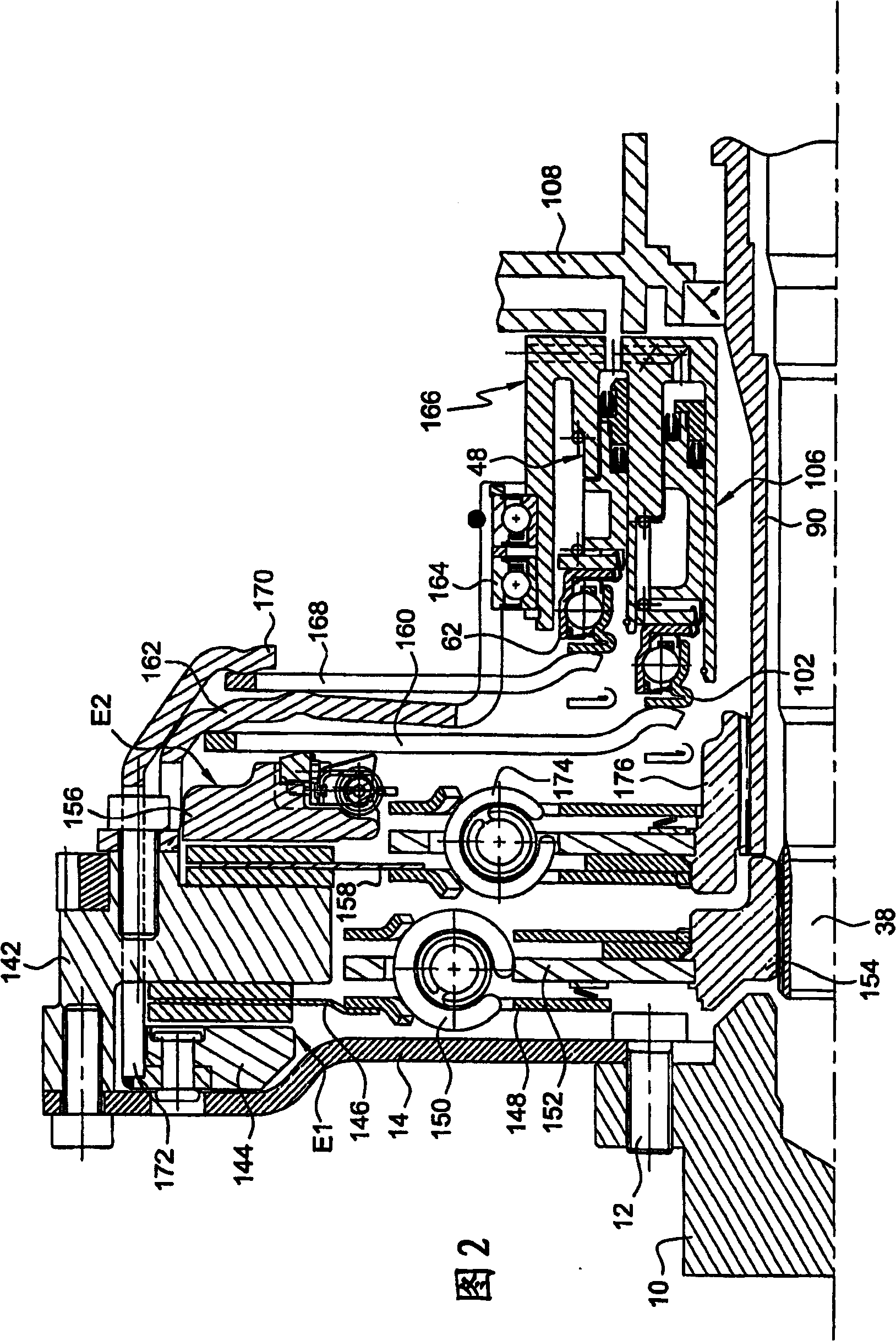

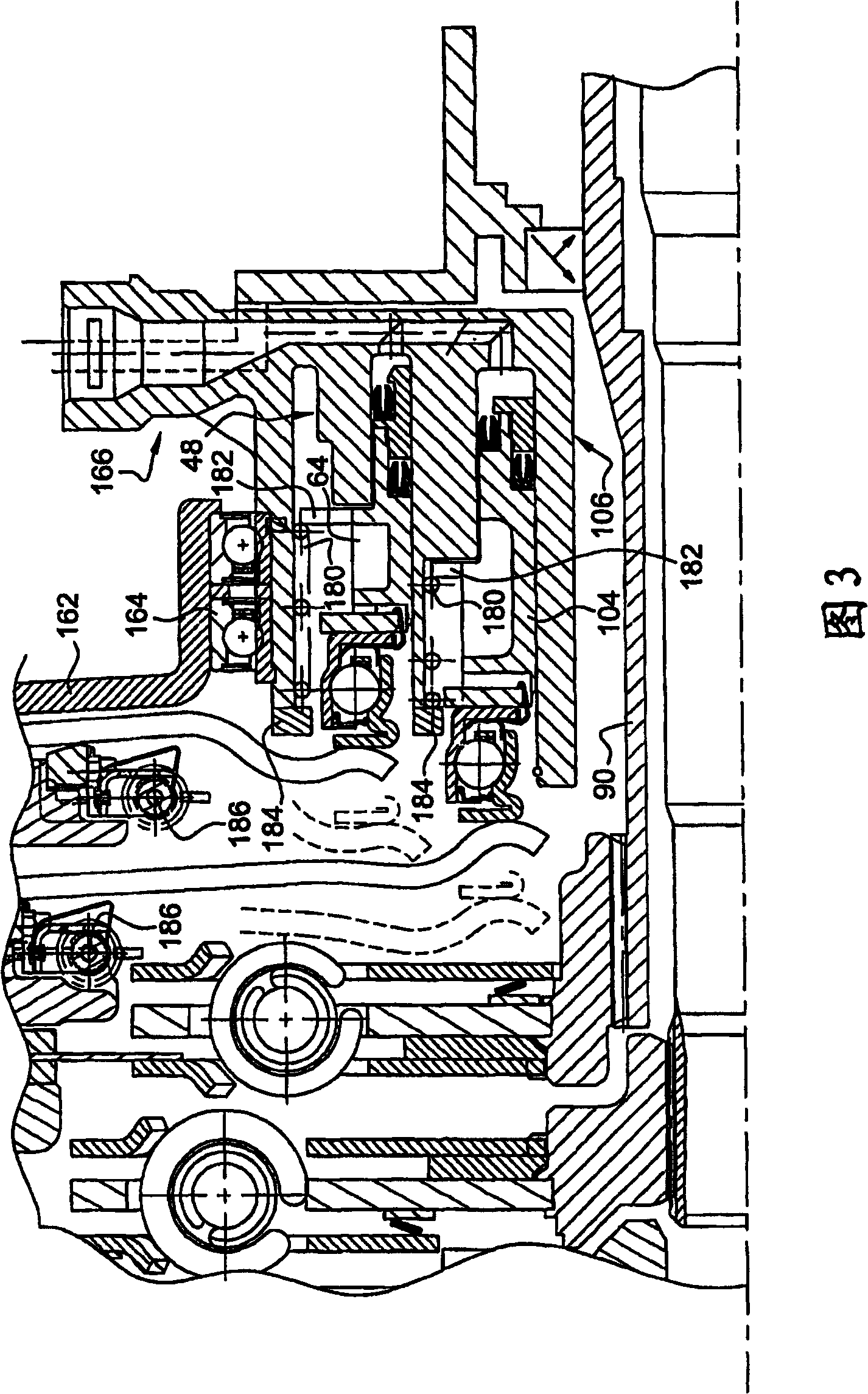

[0035] [35] First refer to FIG. 1, where reference numeral 10 denotes an end of a driving shaft, where the driving shaft is a crankshaft of an internal combustion engine of a motor vehicle, and a first inertia flywheel 11 is fixed on the crankshaft by screws 12. The first inertial flywheel 11 includes a flexible ring-shaped thin steel plate 14, its radially inner part is fixed on the shaft 10 by screws 12, and its radially outer part includes a cylindrical edge 16, which is opposite to the shaft 10. It extends in the direction and has a starting ring 18.

[0036] [36] The radially outer part of the annular thin plate 14 is connected to an input element of a torque buffer 20. This input element is formed by two parallel guide washers 22. The washers 22 include windows in which some coil springs 24 are located. Located in the circumferential direction around the rotating shaft 26 of the device, these springs cooperate with an output element 28 of the torque buffer. The output elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com