A polycrystalline diamond composite sheet and its composite block

A technology of polycrystalline diamond and composite sheet, which is applied in the application of ultra-high pressure process and other directions, can solve the problems of weakening, large pressure loss, and inability to realize rigid pressure transmission, so as to reduce temperature difference, uniform composite interface, and avoid defects point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

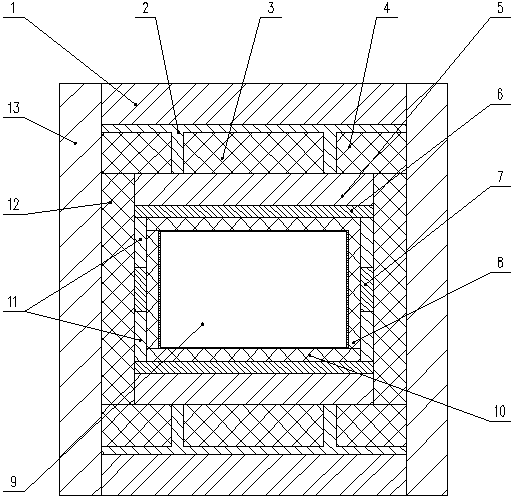

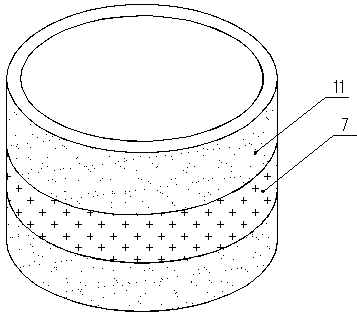

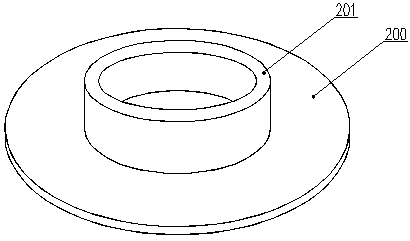

[0034] like Figures 1 to 3 As shown, a synthetic block for polycrystalline diamond compacts includes a synthetic cavity 9 for extruding and sintering polycrystalline diamond blanks, the synthetic cavity 9 is used to place polycrystalline diamond blanks, and the synthetic cavity 9 is sequentially Encapsulation with isolation, heat generation, insulation, and extruded shells:

[0035] The isolation layer includes a cylindrical salt tube 8 that is axially sleeved outside the synthesis chamber 9. The two ports of the salt tube 8 are encapsulated by salt sheets 10, and the outer dimensions of the salt sheet 10 are the same as those of the salt tube 8. The outer dimension of the salt tube 8 and the salt sheet 10 together constitute the isolation layer, and the space in the isolation layer is the synthesis chamber 9. In the present invention, the salt tube 8 and the salt sheet 10 are both made of NaCl. The reason for choosing NaCl The reason is: during the high temperature and high...

Embodiment 2

[0042] A kind of polycrystalline diamond composite sheet that utilizes the synthetic block described in embodiment 1 to prepare, the concrete preparation process of polycrystalline diamond composite sheet comprises the following steps:

[0043] 1) The pyrophyllite block 13 is sintered, the specific process is as follows: firstly, the temperature is raised to 180-230°C and kept for 1-2 hours, then the temperature is raised to 250-270°C and kept for 4-6 hours, and then the temperature is raised to 280-280°C 300 ℃ and keep warm for 2 ~ 3h, finally down to room temperature, that is completed.

[0044] 2) Purify the polycrystalline diamond composite sheet blank, the specific process is: put the polycrystalline diamond composite sheet blank in a vacuum sintering furnace, and evacuate until the pressure in the furnace is 3×10 -3 Pa, at 3×10 -3 Under the condition of Pa, raise the temperature to 450-500°C and keep it warm for 0.5-1h, then fill the furnace with hydrogen until the pres...

Embodiment 3

[0051] A kind of preparation method of polycrystalline diamond composite sheet, it utilizes the synthetic block described in embodiment 1 to finish, and concrete preparation process comprises the following steps:

[0052] 1) The pyrophyllite block 13 is sintered, the specific process is as follows: firstly, the temperature is raised to 180-230°C and kept for 1-2 hours, then the temperature is raised to 250-270°C and kept for 4-6 hours, and then the temperature is raised to 280-280°C 300 ℃ and keep warm for 2 ~ 3h, finally down to room temperature, that is completed.

[0053] 2) Purify the polycrystalline diamond composite sheet blank, the specific process is: put the polycrystalline diamond composite sheet blank in a vacuum sintering furnace, and evacuate until the pressure in the furnace is 3×10 -3 Pa, at 3×10 -3 Under the condition of Pa, raise the temperature to 450-500°C and keep it warm for 0.5-1h, then fill the furnace with hydrogen until the pressure in the furnace is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com