Fuel pipe and preparation method thereof

A fuel pipe and pipe blank technology, which is applied in hoses, pipes, mechanical equipment, etc., can solve the problems of poor fuel penetration resistance, strong rigidity, and hard pipe body, and achieve improved fuel permeability, ultra-low fuel penetration, Good barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

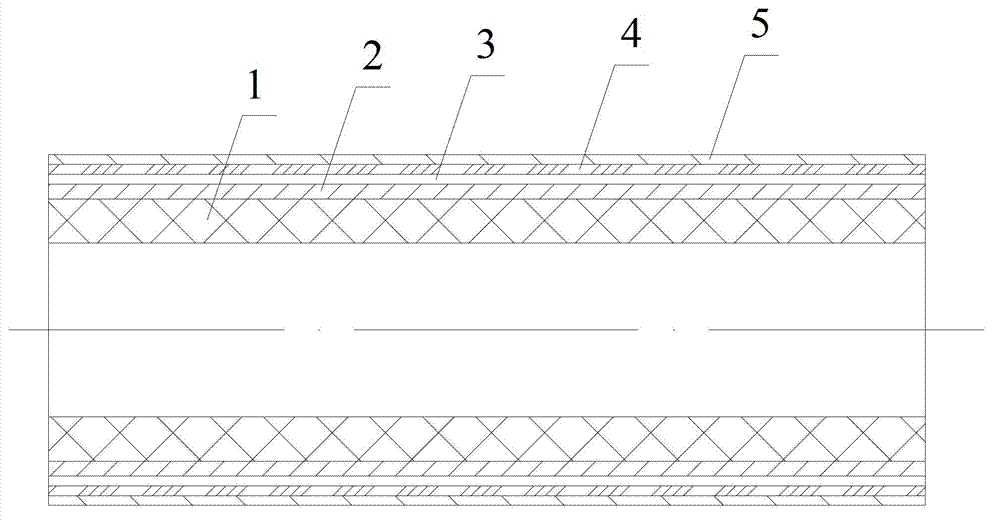

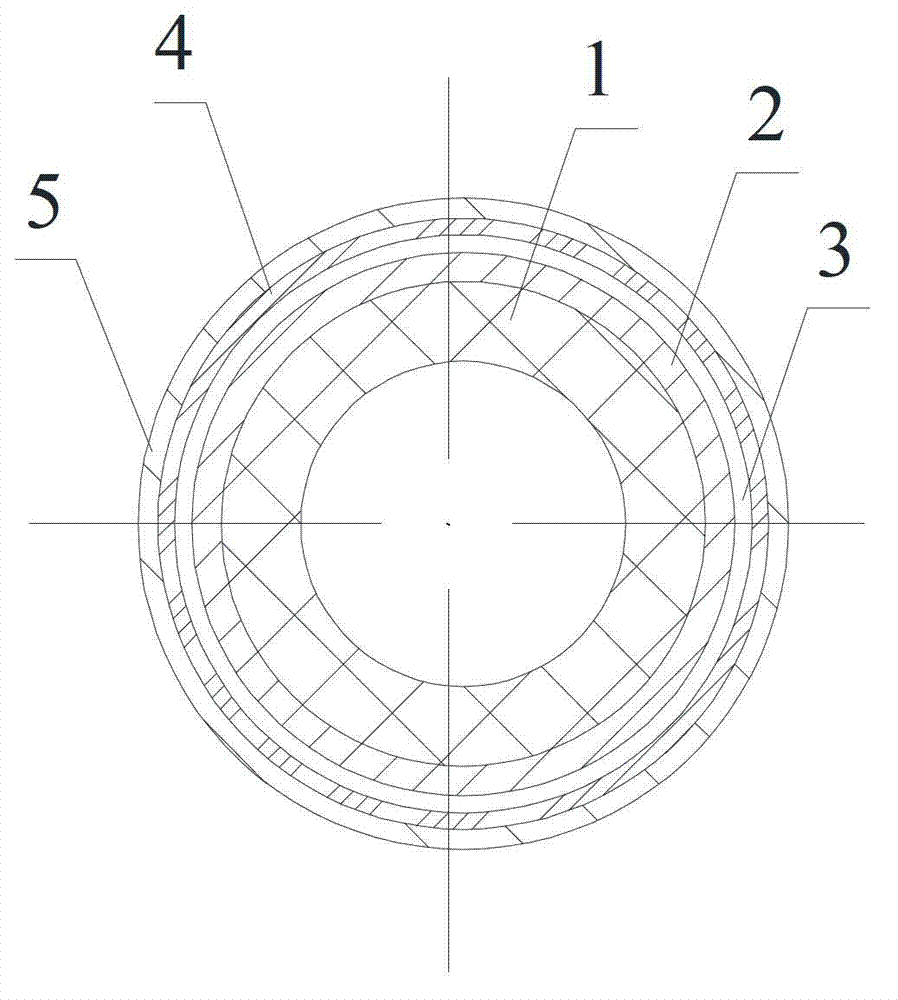

[0036]A fuel pipe with THV fluoroplastic material, from the inside to the outside: NBR nitrile rubber layer 1, THV fluoroplastic material layer 2, NBR nitrile rubber layer 3, aramid fiber layer 4, CSM chlorosulfonated polyamide Vinyl rubber layer5.

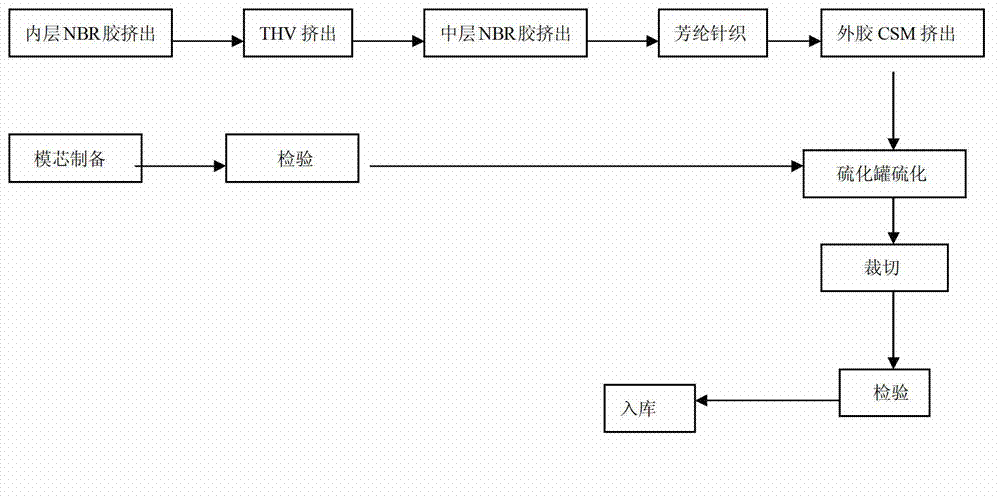

[0037] The preparation method of the fuel pipe comprises the following steps:

[0038] (1) Extrude NBR nitrile rubber from a cold feed extruder into inner rubber;

[0039] (2) Extrude the THV fluoroplastic material from a special plastic extruder to coat the outside of the NBR nitrile rubber inner rubber layer, and then extrude the NBR nitrile rubber to coat the THV fluoroplastic layer through the middle rubber extruder On the outside, the aramid fiber thread is woven on the knitting machine, and finally the CSM chlorosulfonated polyethylene rubber is extruded and coated on the outside of the aramid fiber thread through the outer rubber extruder to form a tube blank;

[0040] (3) Put the tube blank on the special mold core, then...

Embodiment 2

[0042] A fuel pipe with THV fluoroplastic material. The fuel pipe is sequentially composed of a first NBR nitrile rubber layer 1 with a thickness of 1.5mm, a THV fluoroplastic material layer 2 with a thickness of 0.1mm, and a second layer with a thickness of 1mm from the inside to the outside. NBR nitrile rubber layer 3, 0.6mm thick aramid fiber layer 4, 1.4mm thick CSM chlorosulfonated polyethylene rubber layer 5.

[0043] The preparation method of the fuel pipe comprises the following steps:

[0044] (1) Extrude NBR nitrile rubber from a cold feed extruder into inner rubber;

[0045] (2) Extrude the THV fluoroplastic material from a special plastic extruder to coat the outside of the NBR nitrile rubber inner rubber layer, and then extrude the NBR nitrile rubber to coat the THV fluoroplastic layer through the middle rubber extruder On the outside, the aramid fiber thread is woven on the knitting machine, and finally the CSM chlorosulfonated polyethylene rubber is extruded an...

Embodiment 3

[0048] A fuel pipe with THV fluoroplastic material, the fuel pipe is sequentially composed of a first NBR nitrile rubber layer 1 with a thickness of 1.2mm, a THV fluoroplastic material layer 2 with a thickness of 0.16mm, and a second layer with a thickness of 0.4mm from the inside to the outside. Two NBR nitrile rubber layers 3, 0.4mm thick aramid fiber layers 4, 1.4mm thick CSM chlorosulfonated polyethylene rubber layers 5.

[0049] The preparation method of the fuel pipe comprises the following steps:

[0050] (1) Extrude NBR nitrile rubber from a cold feed extruder into inner rubber;

[0051] (2) Extrude the THV fluoroplastic material from a special plastic extruder to coat the outside of the NBR nitrile rubber inner rubber layer, and then extrude the NBR nitrile rubber to coat the THV fluoroplastic layer through the middle rubber extruder On the outside, the aramid fiber thread is woven on the knitting machine, and finally the CSM chlorosulfonated polyethylene rubber is e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com