Axial and radial combined loading bearing test device

A composite loading and bearing test technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of complex structure and operation procedures, difficulty in obtaining test bearing operation data, fluctuation of loading force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

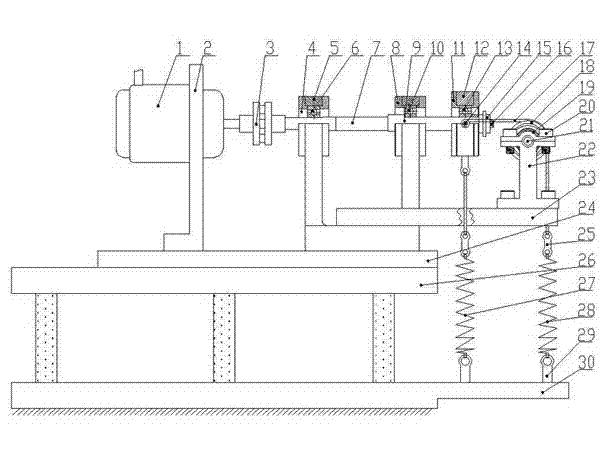

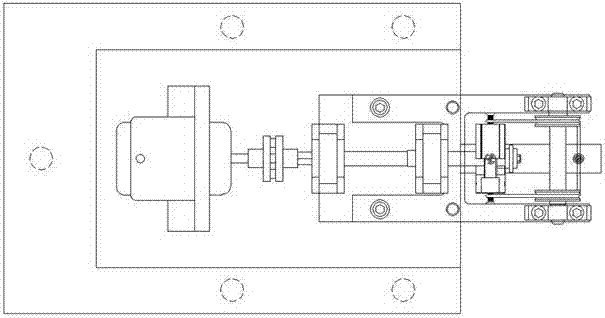

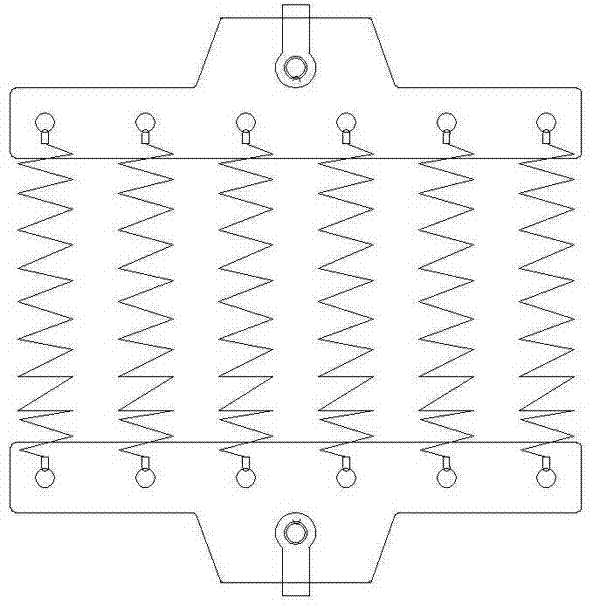

[0014] Such as figure 1 , figure 2 As shown, it is a front view and a top view of the axial and radial compound loaded bearing test device, which is the basic form of the present invention, which mainly consists of a motor 1, a motor support 2, a shaft coupling 3, a supporting bearing shoulder 4, a supporting bearing 5. Support bearing seat 6, main shaft 7, shaft step 9, test bearing 10, loading bearing outer casing 12, loading bearing 13, axial loading rod 14, shaft locking washer 15, axial locking nut 16, loading rope 17, fixed Pulley 18, radially loaded spring 27 and axially loaded spring 28 form. The test bearing 10 is under the action of the radial loading spring 27, the axial loading spring 28, the loading bearing 13 and the shaft step 9 respectively, and is loaded in both radial and axial directions at the same time, and is tested at a given speed of the motor 1 Under this condition, composite test conditions with different radial load, axial load and rotational spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com