Contact thermal resistance measuring device capable of adjusting loading force and temperature within wide range

A contact thermal resistance and measuring device technology, applied in the field of thermophysical property measurement of solid materials, can solve the problems of adjusting loading force, axial heat flow measurement error, freezing of refrigeration liquid, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

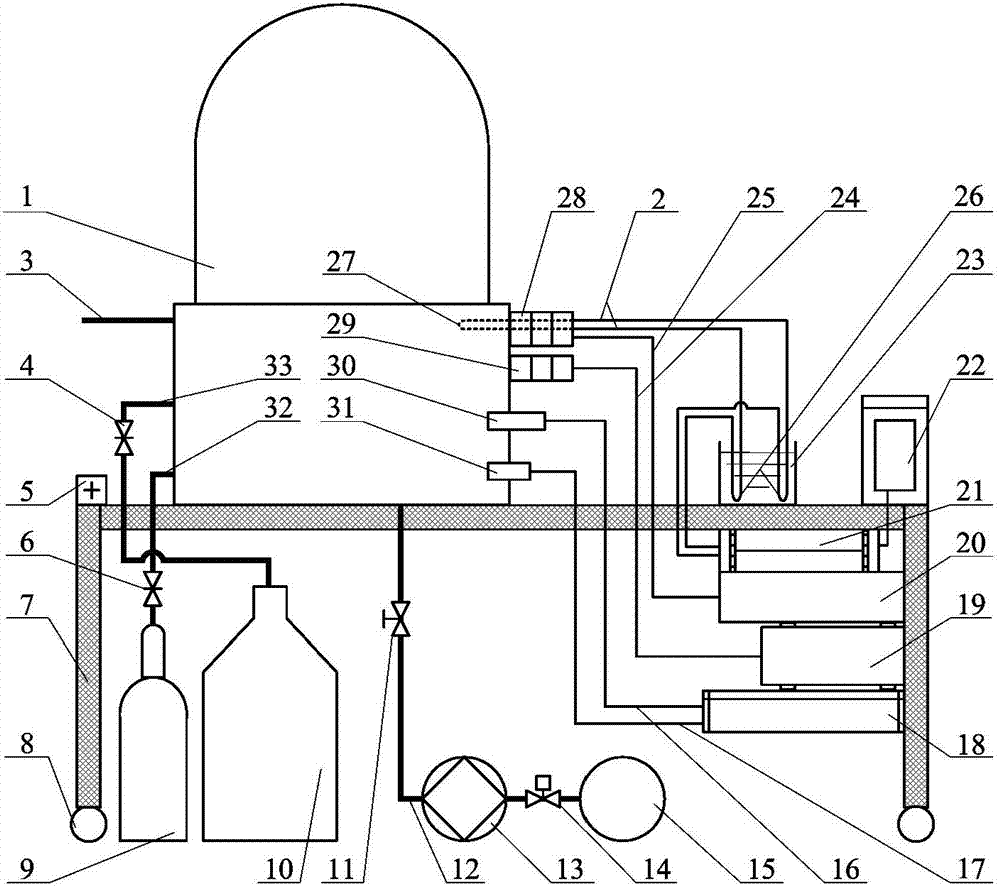

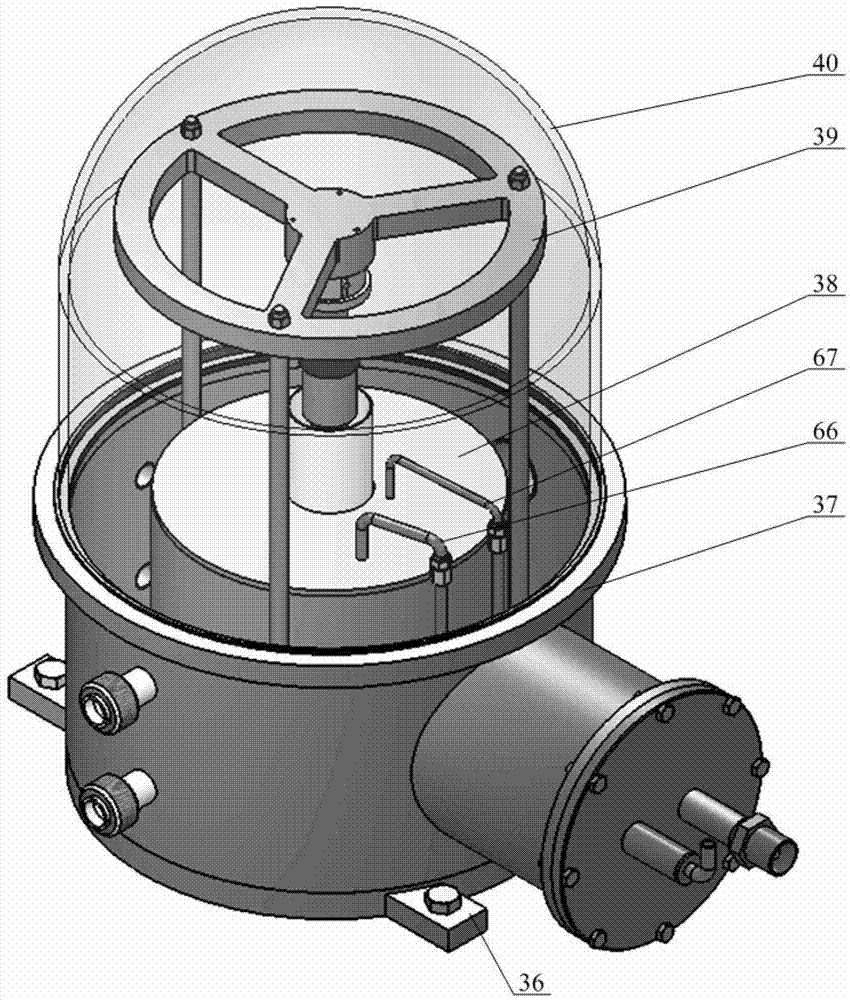

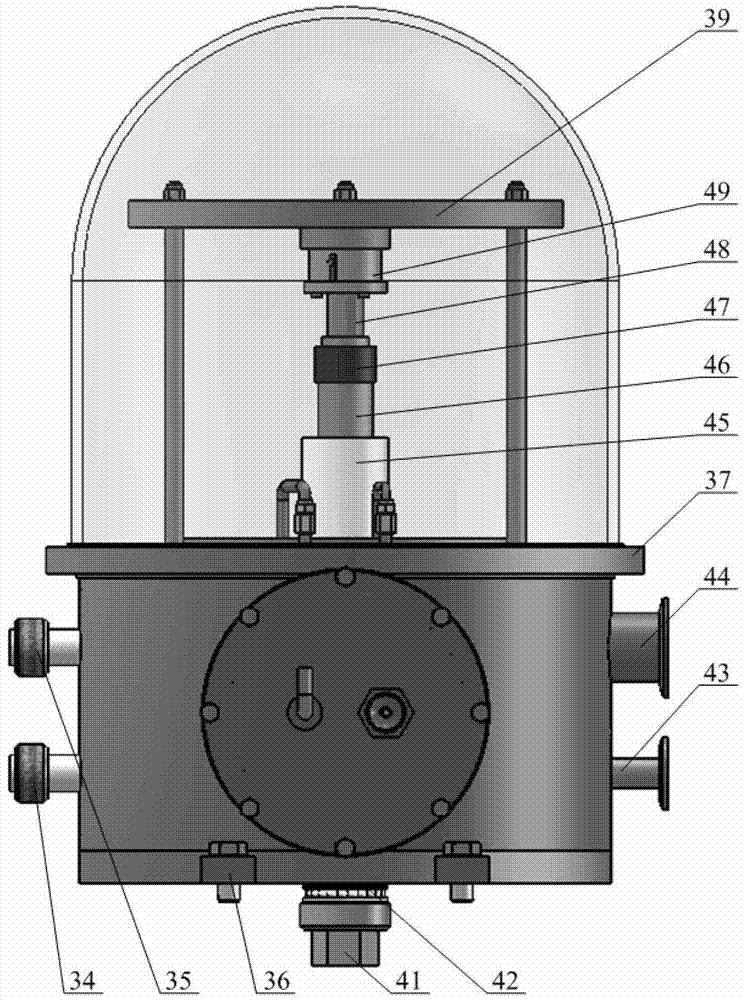

[0021] refer to figure 1 with Figure 2a , a contact thermal resistance measuring device capable of adjusting loading force and temperature in a wide range, including a measuring unit 1, the vacuum chamber fixing feet 36 of the measuring unit 1 are connected to the upper surface of the frame 7 by bolts. There are four vacuum chamber fixing legs 36, all of which are welded on the vacuum chamber 37. The frame 7 is made of angle steel, 1.2m long, 0.6m wide, and 1.2m high. The upper surface of the frame 7 is laid with steel plates, and the inside of the frame 7 is welded with an instrument box. A level 5 is placed on the upper surface of the frame 7, and the level 5 is a portable L-shaped bubble level. The bottom of the frame 7 is connected with the universal wheel 8, and the adjacent position of the universal wheel 8 is equipped with a height-adjustable suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com