Wide-range wavelength-tunable etalon

An etalon and wide-ranging technology, applied in the field of optical etalons, can solve problems such as difficult to realize wavelength adjustment, small wavelength adjustment range, and limited applicable range, etc., and achieve the effect of simple structure, easy production and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

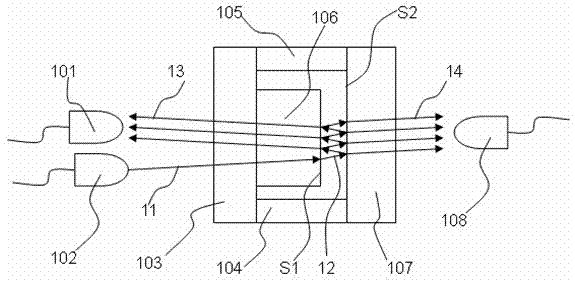

[0031]In this embodiment, in order to realize that the cavity length of the above-mentioned resonant cavity can change with temperature, the etalon in this embodiment contains temperature-sensitive materials, specifically including two substrates and three transition layers. These two substrates have the same structure, specifically the first substrate 103 and the second substrate 107 arranged in parallel, the three transition layers are respectively two side transition layers and a central transition layer 106, the two side transition layers The reference numbers are 104 and 105, respectively. The thickness of the central transition layer 106 is less than the thickness of the two side transition layers, and the two side transition layers have the same shape and are erected between the two substrates parallel to each other, and the central transition layer 106 is arranged in the middle of the two side transition layers. One surface of the central transition layer 106 is closel...

Embodiment 2

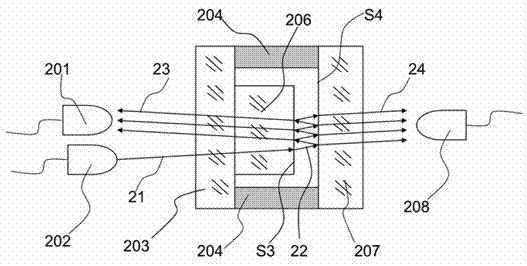

[0045] In this embodiment, in order to realize that the cavity length of the above-mentioned resonant cavity can change with temperature, the etalon in this embodiment includes two pieces of temperature-sensitive materials. Specifically, there are two substrates made of transparent materials and a transition layer made of temperature-sensitive materials. like figure 2 As shown, the two substrates include a first substrate 203 and a second substrate 207 arranged in parallel, and the two transition layers are a central transition layer 206 and an annular tubular side transition layer 204 respectively. The thickness of the central transition layer 206 is smaller than that of the side transition layer 204 , and the annular tubular side transition layer 204 is erected between two substrates during installation, and the central transition layer 206 is disposed in the middle of the side transition layer 204 . One surface of the central transition layer 206 is closely attached to an...

Embodiment 3

[0055]In this embodiment, in order to realize that the cavity length of the above-mentioned resonant cavity can change with temperature, the etalon in this embodiment includes two kinds of materials. Specifically, there are two substrates made of transparent materials and a transition layer made of different materials. The structural form of this embodiment and embodiment 2 is identical, and the difference is that the thermal expansion coefficient difference of two kinds of materials that make transition layer is bigger, and promptly side transition layer 204 selects the material that thermal expansion coefficient is α1 for use, and this material is at temperature T0 The length is L1; the central transition layer 206 in the middle is a material with a thermal expansion coefficient α2, and its length is L2 at the temperature T0. Wherein, the coefficient of thermal expansion α1 is much smaller than the coefficient of thermal expansion α2, and the ideal situation is that the coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com