Card box lifting mechanism of card sender and card sender using the same

A technology of a card issuing machine and a lifting mechanism, which is applied in the field of card issuing machines, can solve the problems of complex mechanism and long time for assembling and disassembling the card box, and achieves the effects of reliable operation, simple structure, and firm assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

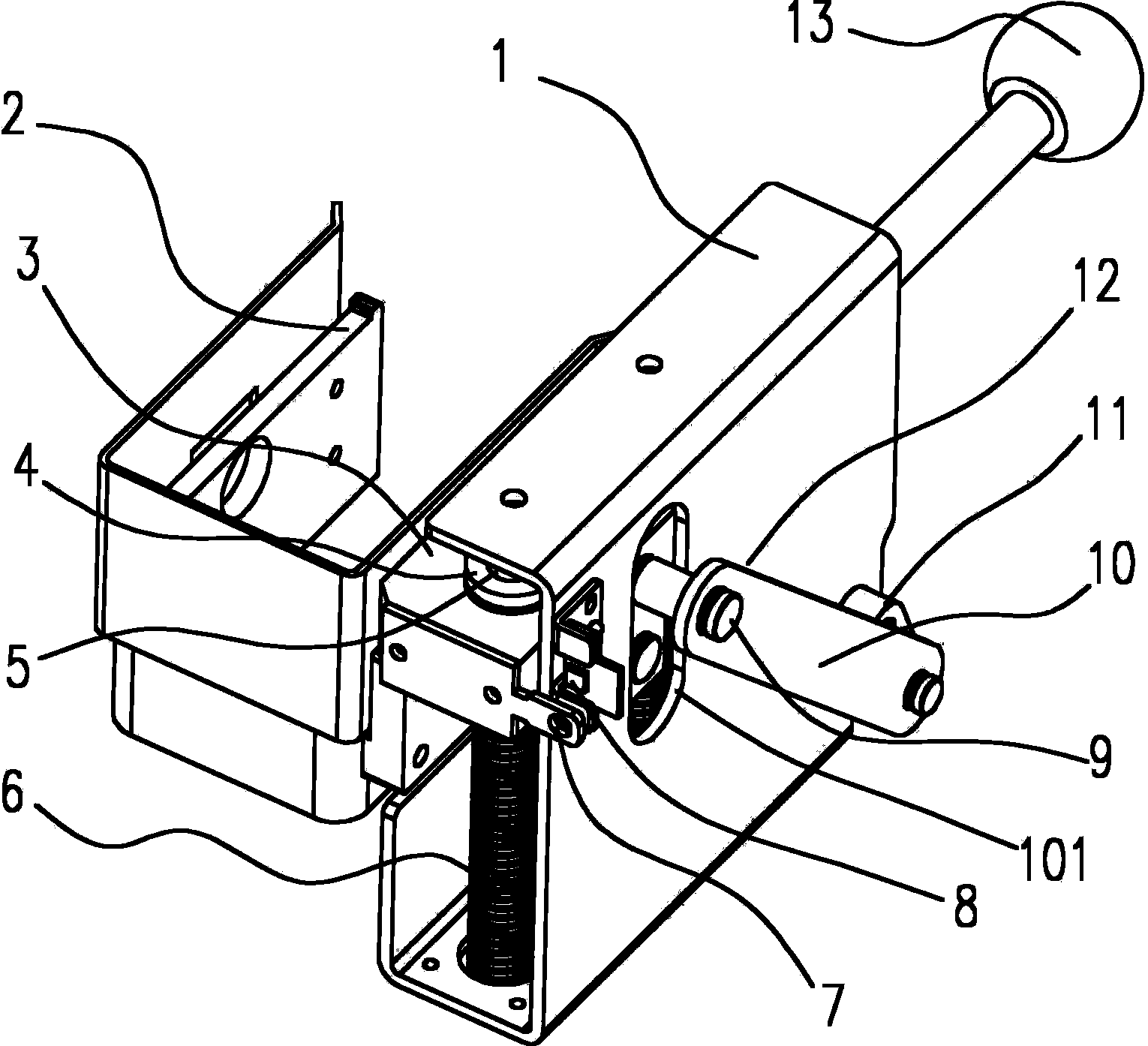

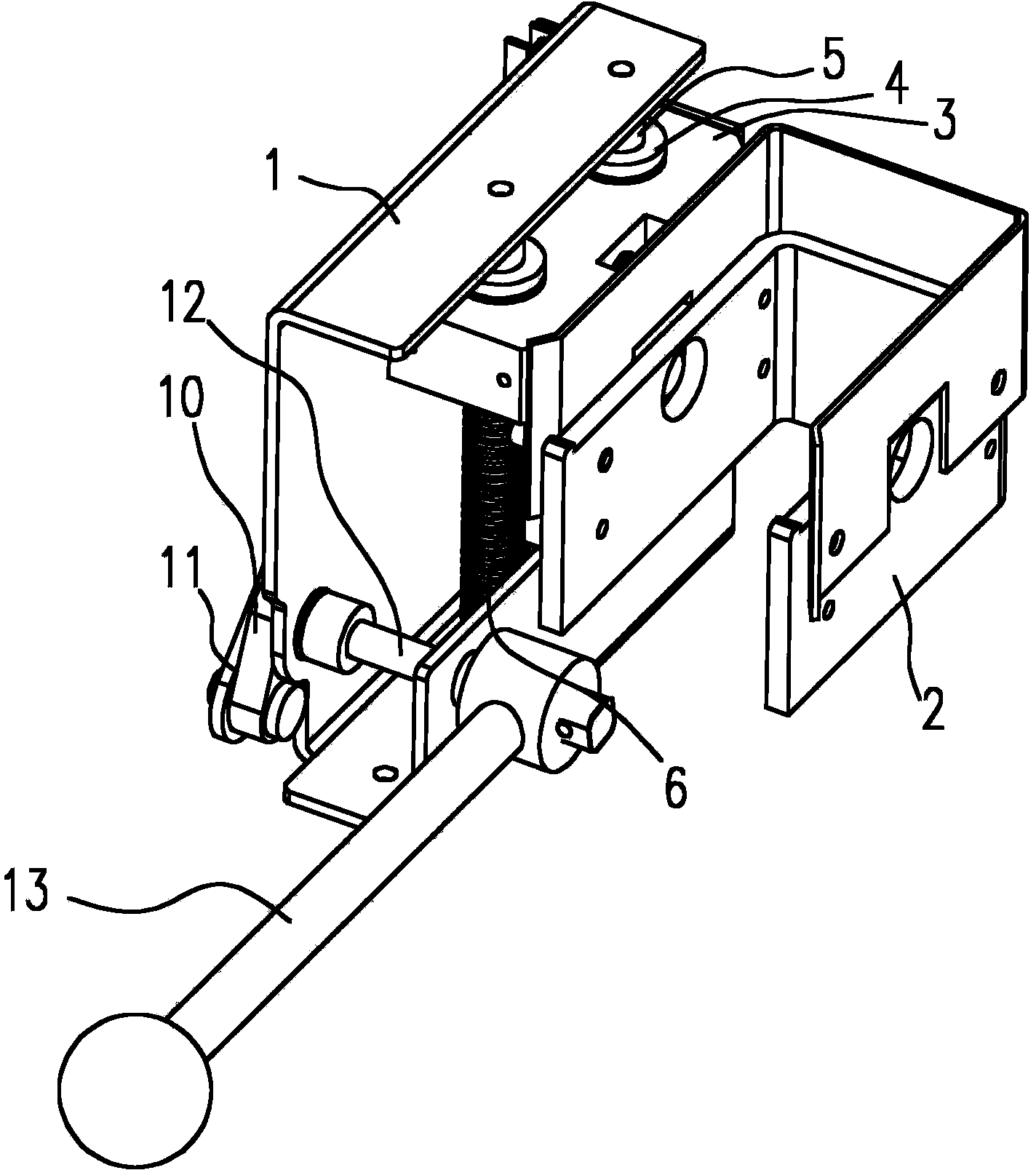

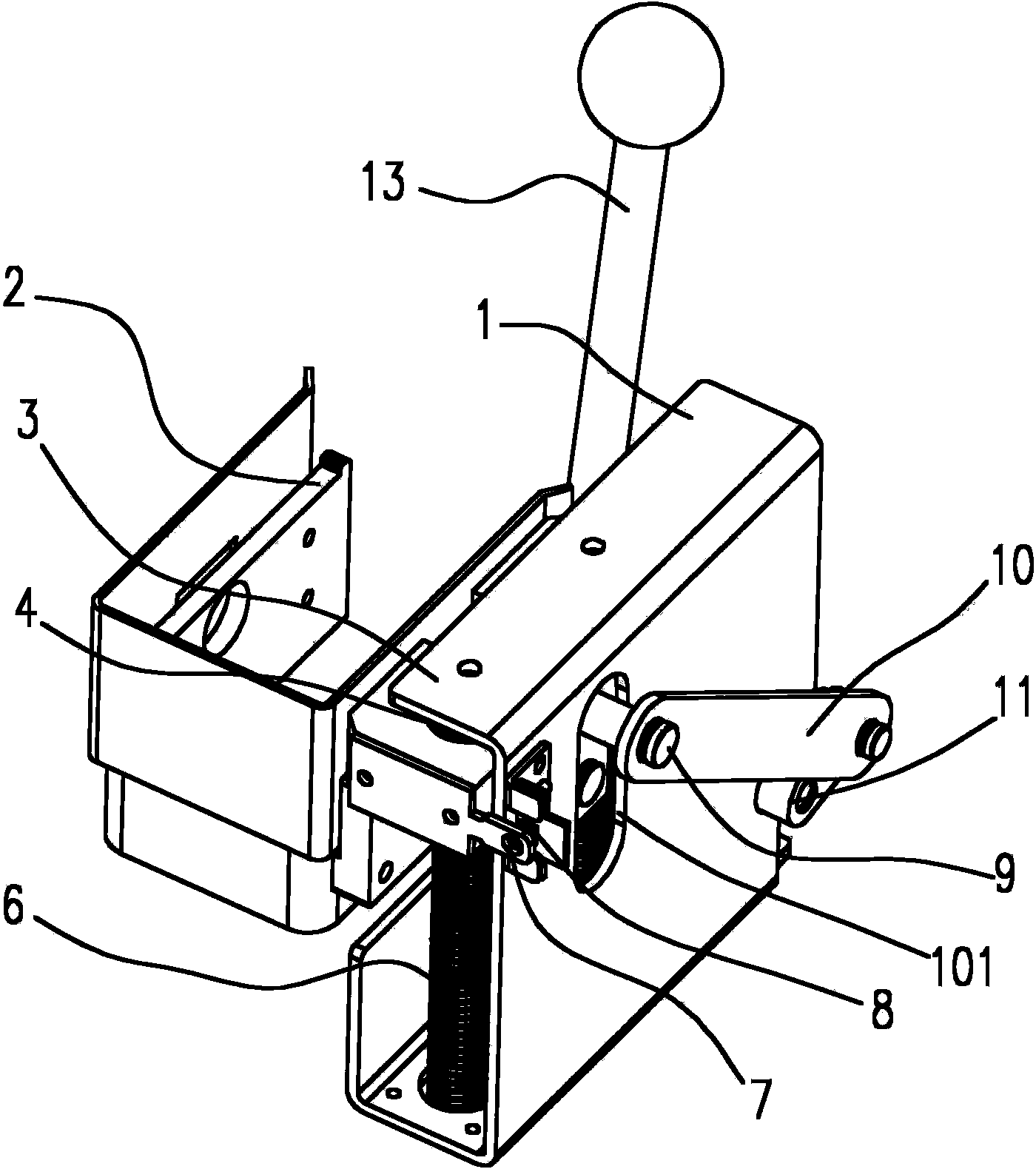

[0025] like Figures 1~4 The shown card box lifting mechanism of a card issuing machine includes a bracket 1, a slider 3, a guide column 5, a card box support plate 2 for supporting the card box 16, and a lifting mechanism for driving the slider to lift. The column 5 is vertically installed on the bracket 1, and the lifting mechanism is installed on the bracket 1 and has a start end for starting the lifting action and an output end for outputting the lifting action.

[0026] The lifting mechanism includes a handle rod 13, a crank 11, a connecting rod 10 and a connecting column 9. A conduction shaft 12 extends laterally from the end of the handle rod 13, and the conduction shaft 12 is hinged on the bracket 1; one end of the crank 11 is mounted on the On the conduction shaft 12, the other end of the crank 11 is hinged with one end of the connecting rod 10; the bracket 1 is provided with a chute 101 for the vertical sliding of the connecting column 9, and the rear end of the conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap