Single-phase bridge rectifier

A single-phase rectification and bridge stack technology, applied in the direction of converting AC power input into DC power output, electrical components, circuits, etc., can solve the problems of low production efficiency, high labor intensity, scrapped finished products, etc., to improve the heat dissipation effect and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

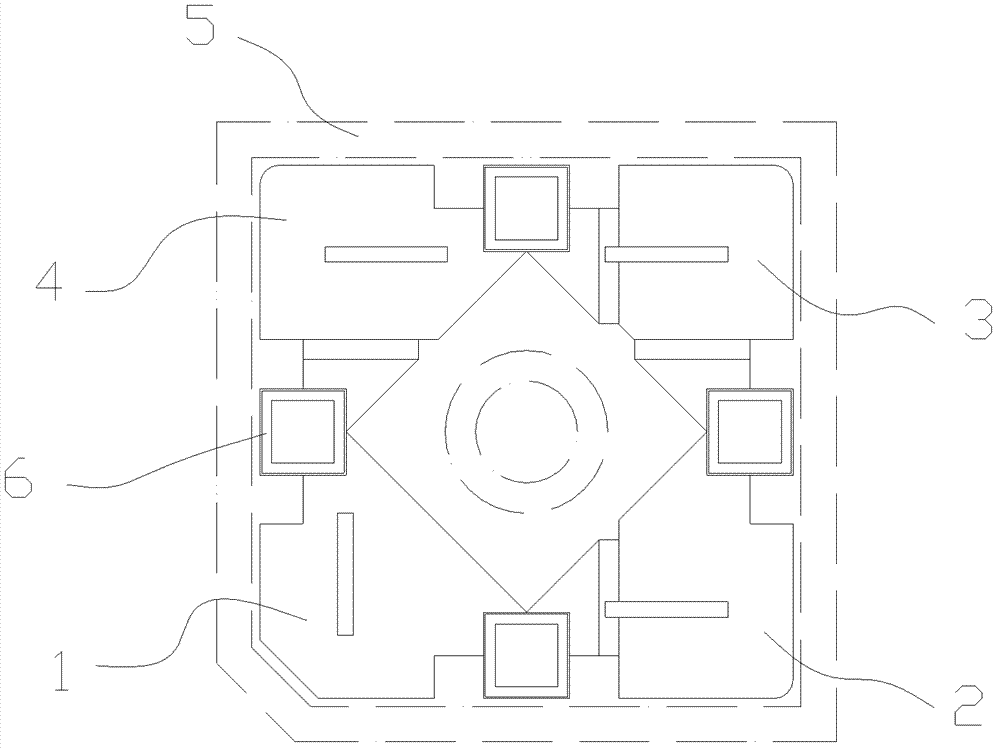

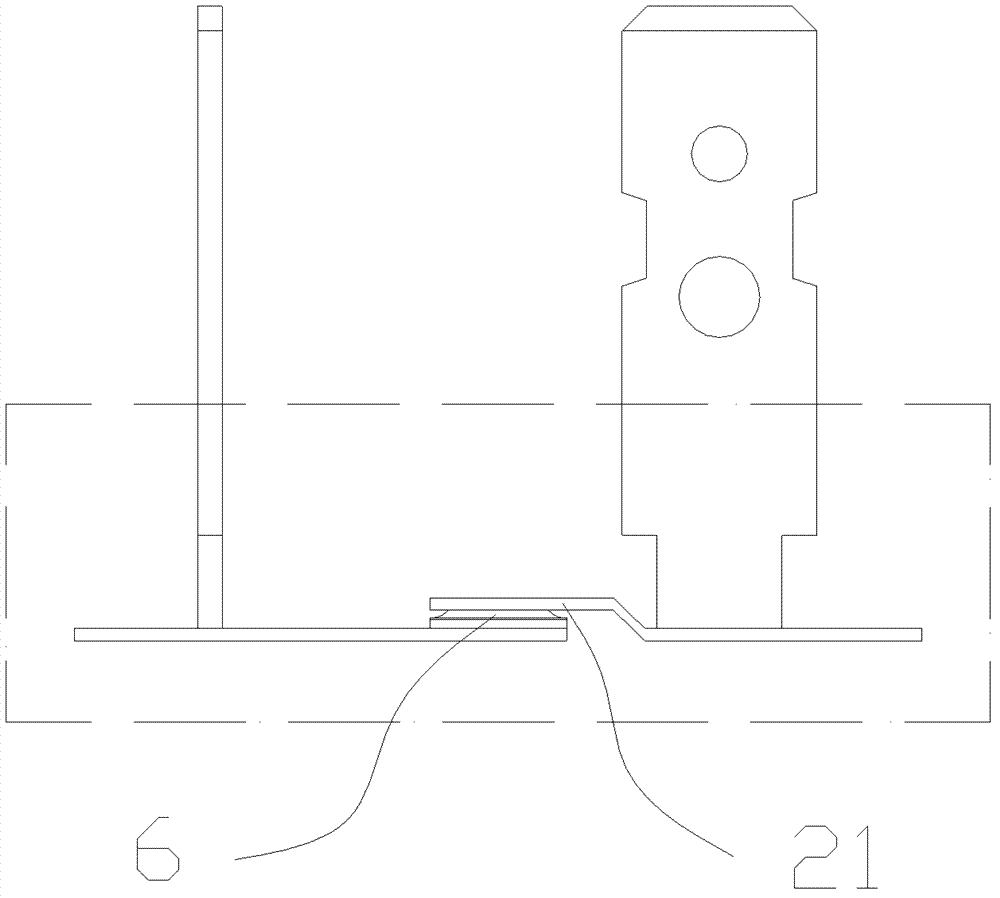

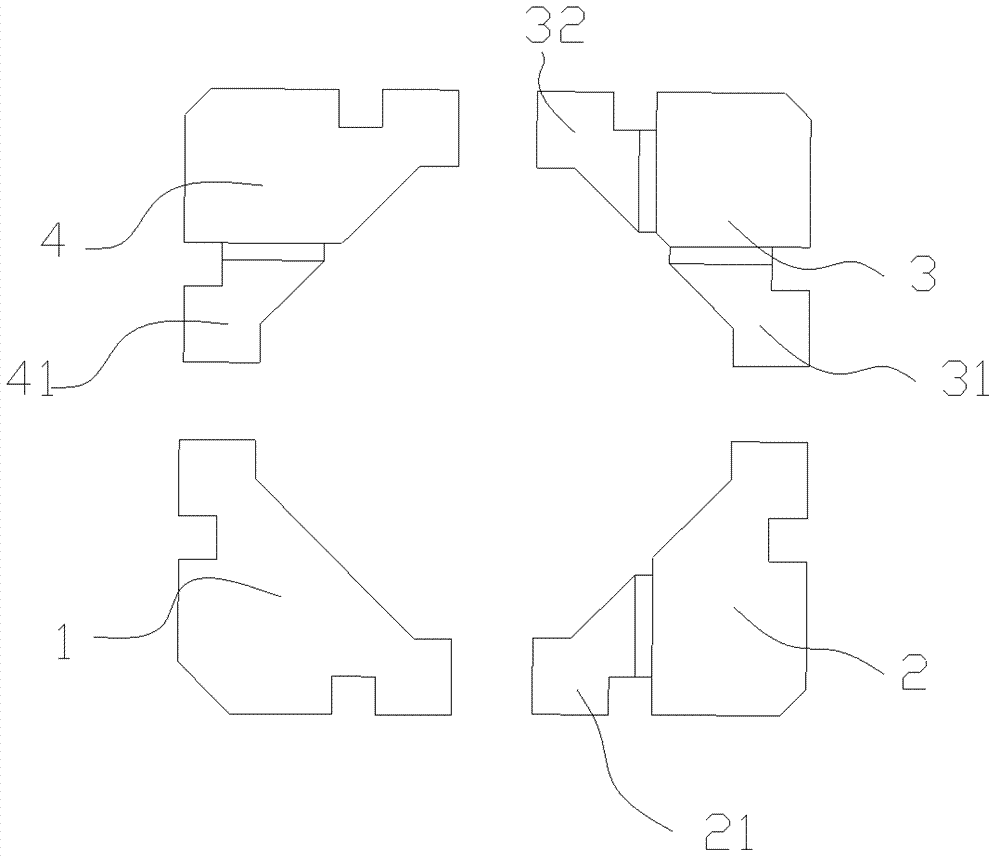

[0012] The present invention as Figure 1-3 As shown, it includes a package body 5, frames one to four (1, 2, 3, 4) and four chips 6, the bodies of the frames one to four are sheet-shaped, and the planar shape of the sheet-shaped body is an isosceles right triangle , each frame is respectively provided with pins perpendicular to the frame body, and the oblique angles of frames one to four are sequentially connected so that the four frames form a square outline, and the frame two 2 faces the acute corner of frame one 1, and frame three The two acute-angled corners of 3 and the acute-angled corners of frame 4 4 towards frame 1 are respectively bent toward the direction of setting pins and out of the parallel step planes of each frame body; the N faces of the four chips are respectively welded on the frame Two acute angle corner planes of one 1, the acute angle corner plane of frame two 2 towards frame three 3, and the acute angle corner plane of frame four 4 towards frame thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com