exposure system

An exposure system and polarizer technology, applied in the field of exposure systems, can solve the problems of irregular polarization patterns, low efficiency, and uneven exposure in the exposure area, and achieve uniform and accurate polarization pattern formation, minimized light loss, and uniform exposure and the effect of pattern formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

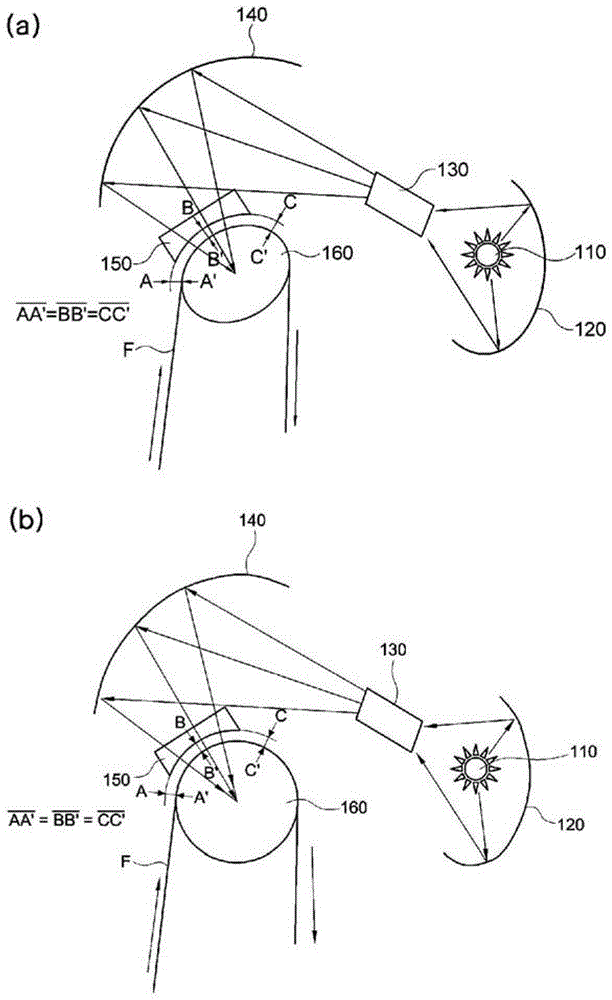

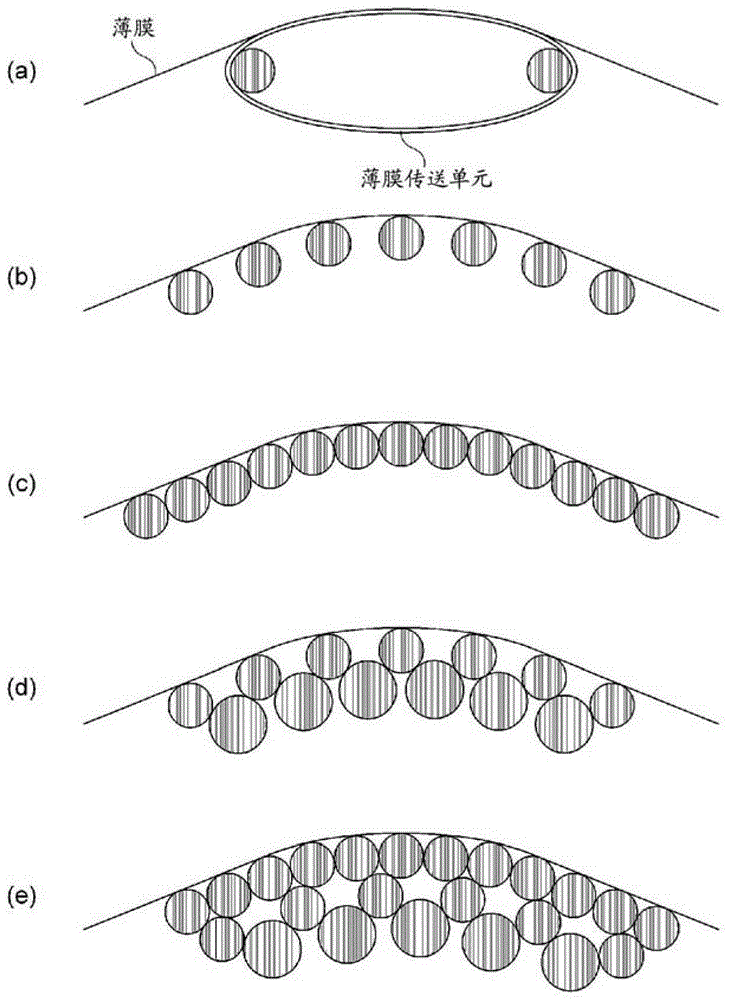

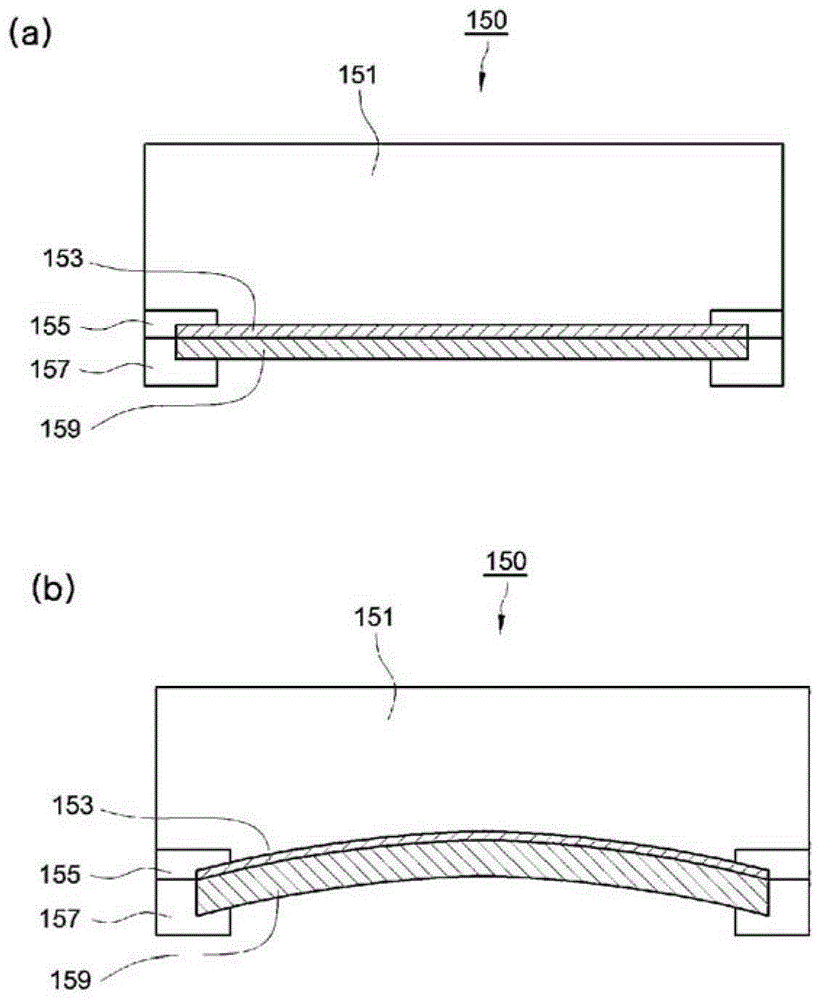

[0041] The exposure system involved in the present invention includes: a light-emitting unit; a film transfer unit, the film is attached to its surface, and is bent into a circle, an ellipse or a state with partial curvature to be transported; and a pattern forming unit, which transmits the light emitted by the above-mentioned light-emitting unit The above-mentioned film bonded to the above-mentioned film, and form a polarizing pattern on the above-mentioned film, thereby, in the case of continuously unwinding the film wound on the roller and forming a polarizing pattern, the vibration and bending of the film can also be minimized, and the Uniform exposure over a wider area contributes to the improvement of the quality of pattern retarders, etc. and the improvement of production efficiency.

[0042] The present invention will be described in detail below.

[0043] The exposure system of the present invention, for example figure 1 composition shown. figure 1 The exposure syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com