Method of weaving multi-layer carpet with polybutylece terephthalate (PBT) filament

A multi-level, carpet technology, applied in the field of carpet weaving, can solve the problems of high price of cut flowers, many carpet colors, large one-time volume, etc., and achieve the effects of avoiding unstable quality, good three-dimensional effect and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

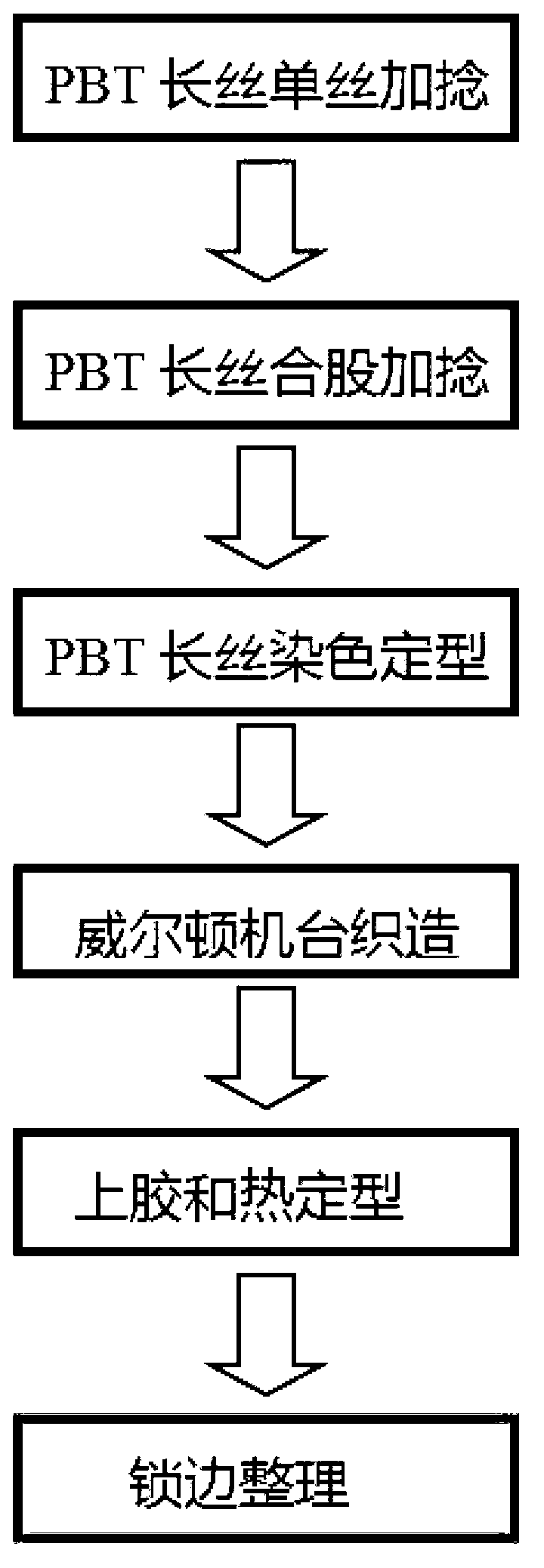

Method used

Image

Examples

Embodiment 1

[0049] 1) Use 100 kilograms of 300D / 72F PBT monofilament to twist and weave into PBT yarn, the twist is 250 twists / m, and the twist direction is "Z" twist direction. During the doubling process, add 0.5 % of mineral oil;

[0050] 2) Plying and twisting again, the PBT yarn obtained in the above steps is twisted again, 300D / 2 ply yarn is plyed and twisted, the twist is 180 twists / m, and the twist direction is set as "S" twist direction. The technical requirements for twisting are relatively high, and the twist deviation must be controlled within 2%;

[0051] 3) Yarn dyeing and setting: Dyeing determines the color according to the carpet pattern, and the heat setting requirements of the yarn are very high. The heat setting method is carried out in a hot oven. The temperature of the oven is controlled at 70°C, the oven time is 40 minutes, and the shrinkage rate reaches 28%. ;

[0052] 4) Carpet weaving operation: Wilton machine is selected for weaving thin blankets. Mix 300D / 2 ...

Embodiment 2

[0056] 1) Use 100 kilograms of 300D / 72F PBT monofilament to twist and weave into PBT yarn. The twist is 270 twists / m, and the twist direction is "Z" twist direction. During the doubling process, 1 % of mineral oil;

[0057] 2) Plying and twisting again, the PBT yarn obtained in the above steps is twisted again, 300D / 2 ply yarn is plyed and twisted, the twist is 190 twists / m, and the twist direction is set as "S" twist direction. The technical requirements for twisting are relatively high, and the twist deviation must be controlled within 3%;

[0058] 3) Yarn setting: The heat setting requirements of yarn are very high, and heat setting is carried out by using a hot oven method. The temperature of the oven is controlled at 90°C, the oven time is 30 minutes, and the shrinkage rate reaches 21%;

[0059] 4) Carpet weaving operation: Wilton machine is selected for weaving thin blankets. Mix 300D / 2 strands of PBT yarn and polypropylene yarn with 800 dtex / 150F single twist yarn, co...

Embodiment 3

[0063] 1) Use 100 kilograms of 300D / 72F PBT monofilament to twist and weave into PBT yarn. The twist is 260 twists / m, and the twist direction is "Z". % of mineral oil;

[0064] 2) Plying and twisting again, the PBT yarn obtained in the above steps is twisted again, 300D / 2 ply yarn is plyed and twisted, the twist is 175 twists / m, and the twist direction is set as "S" twist direction. The technical requirements for twisting are relatively high, and the twist deviation must be controlled within 3%;

[0065] 3) Yarn setting: The heat setting requirements of yarn are very high, and heat setting is carried out by using a hot oven method. The temperature of the oven is controlled at 80°C, the oven time is 35 minutes, and the shrinkage rate reaches 30%;

[0066] 4) Weaving operation: Wilton machine is selected for thin blanket weaving. Mix 300D / 2 strands of PBT yarn and polypropylene yarn with 800 dtex / 150F single twist yarn, control the warp and weft density to 512 warp x 420 weft;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com