Method for collecting solar energy and its heating apparatus

A heating device and solar energy technology, which is applied in solar thermal devices, solar thermal power generation, heating devices, etc., can solve problems such as inconvenient maintenance, difficult installation and construction, and large changes in ambient temperature, so as to reduce manufacturing costs and difficulty in construction , Improve operational reliability, low heat recovery and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

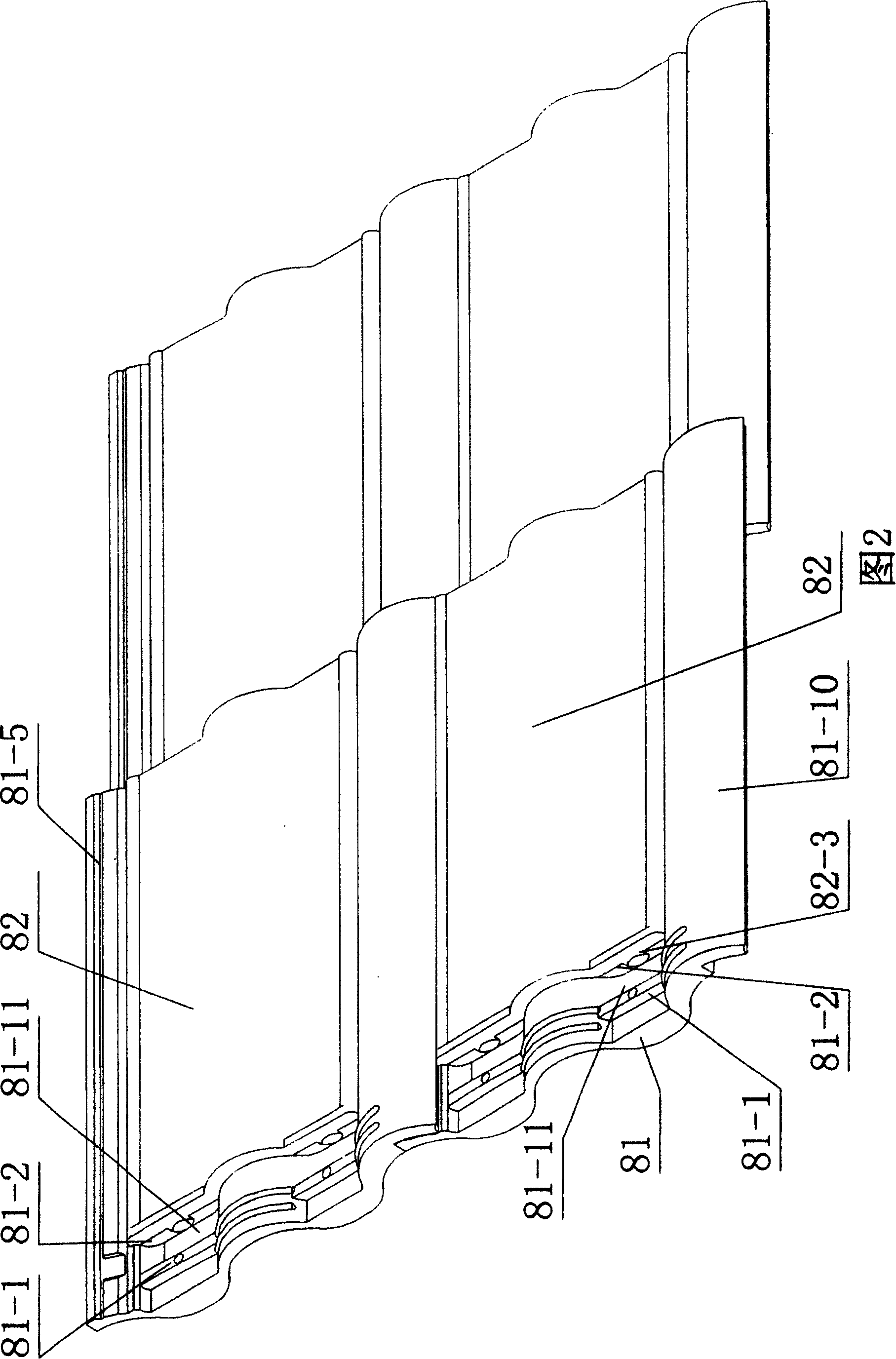

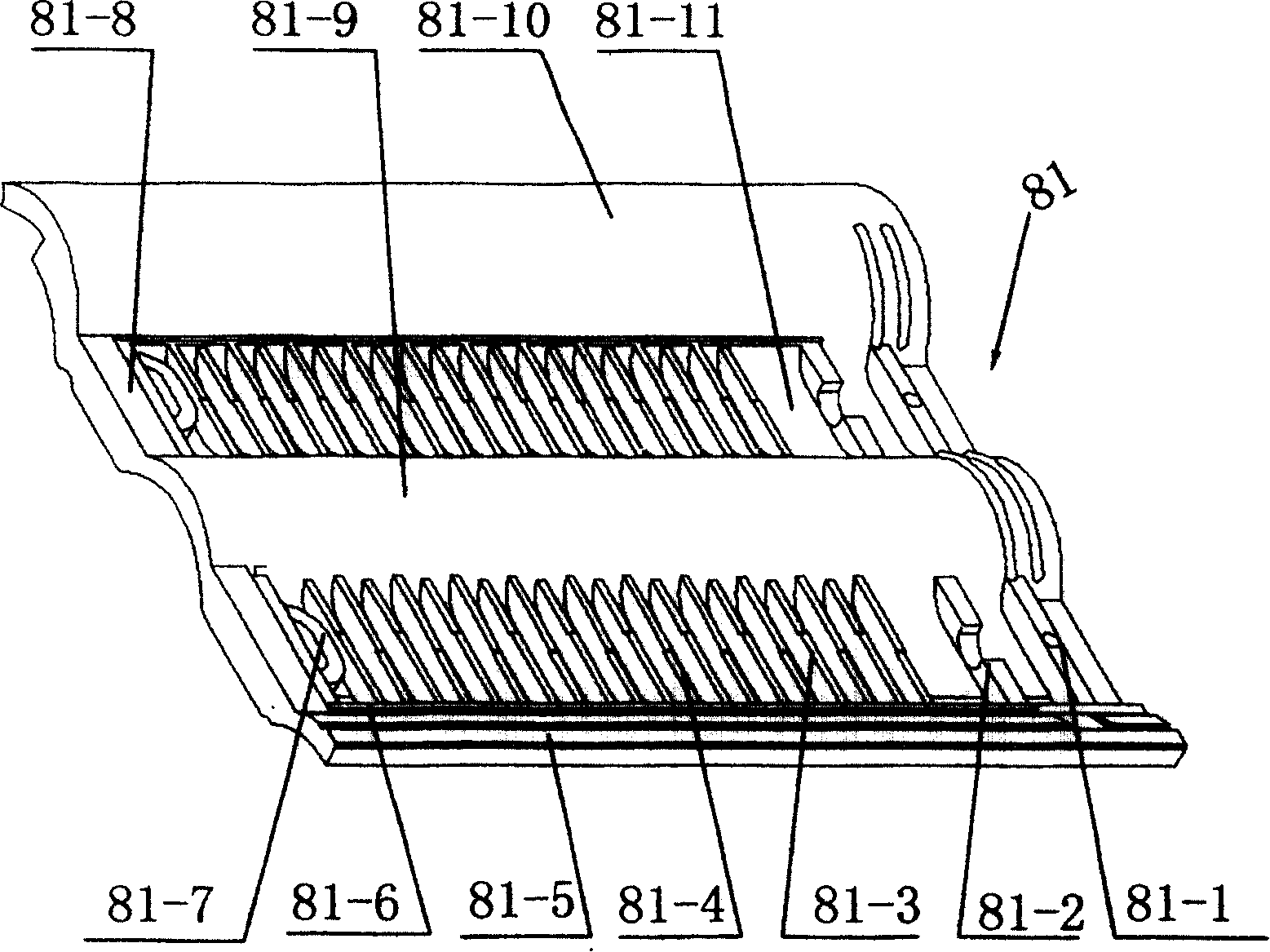

[0023] The method for collecting solar energy of the present invention is to lay a plurality of roof tiles 8 adjacent to each other vertically and horizontally on the inclined roof. The roof tiles 8 have a built-in atmospheric bypass flow channel. There are multiple groups of parallel liquid channels that are open vertically to the atmosphere. The liquid flowing from top to bottom in the liquid channels of the roof tile 8 absorbs solar heat or / and air heat through the tile body, and the liquid adsorbed in the liquid channel adsorption layer absorbs heat. After desorption, one-way heat transfer is formed, and the liquid absorbs heat as a low-temperature heat source.

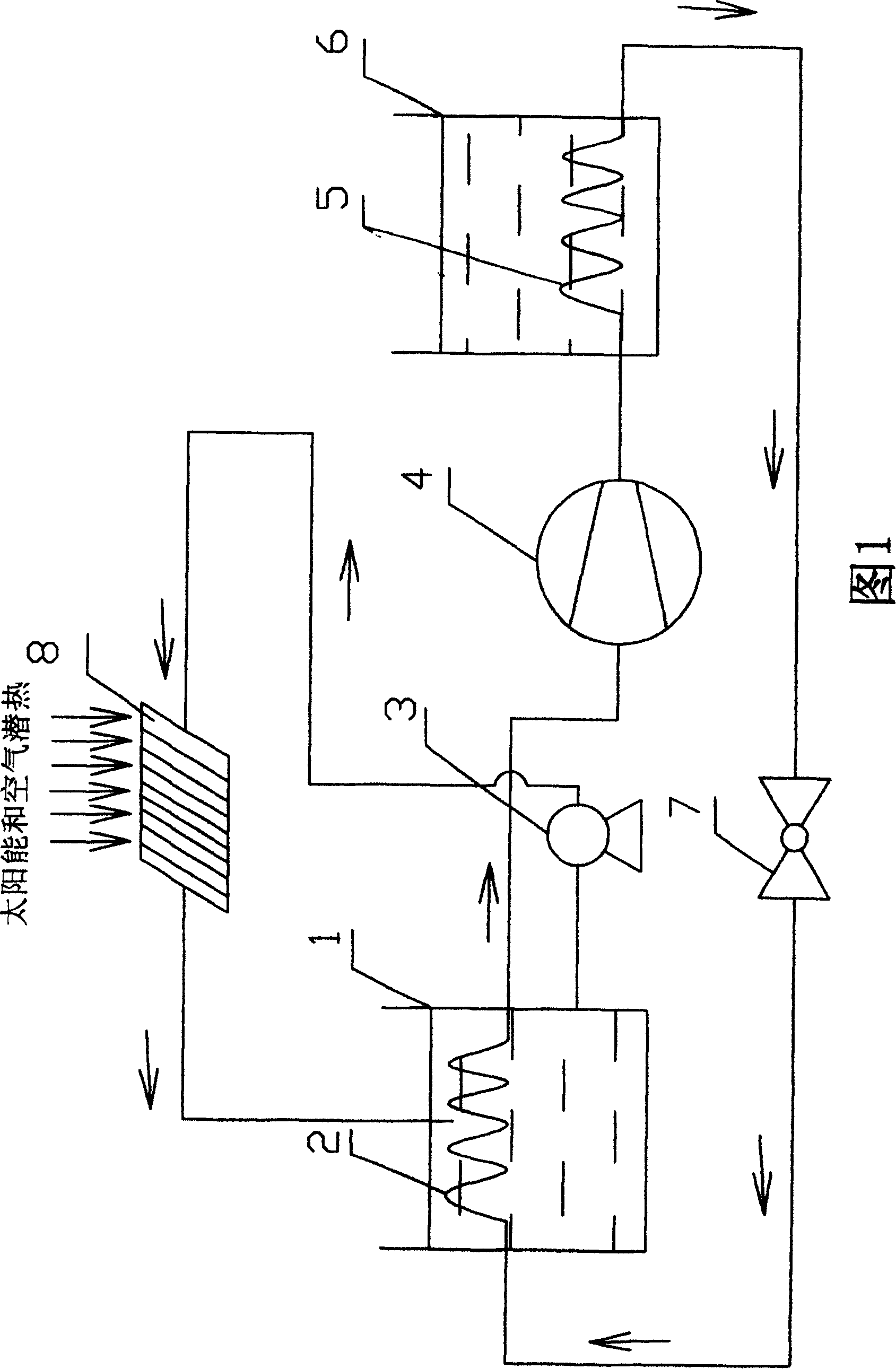

[0024]See the solar heating device of the present invention shown in Fig. 1, comprise roof tile 8, the evaporator 2 that is arranged in the heat storage tank 1 of heat medium, the compressor 4 and the condenser 5 that are arranged in the storage tank 6 and expansion valve 7. The pipeline connects the evaporator 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com