Score cut compact mode sectioning method of cold rolled aluminum roll

A technology of slitting and slitting aluminum coils, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of production difficulties, the formation of a large number of stripes, the time-consuming and labor-intensive tension pads, etc. Health hazards, production cost savings, and the effect of solving heat and fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

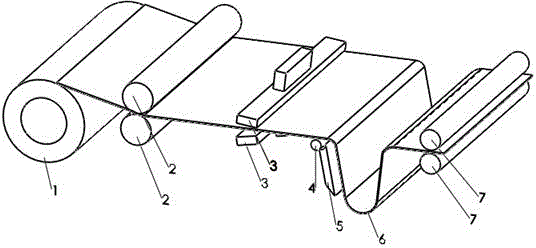

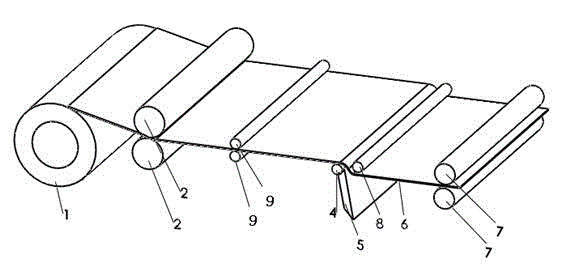

[0013] The slitting method of the cold-rolled aluminum coil in the slitting mode of the present invention is as follows: on the slitting and slitting production line of the cold-rolled aluminum coil, a set of liftable flattening and tensioning devices are respectively installed before and after the separation plate to fix the strip The height of the material at the separation disc, so that the strip and the separation disc have a certain wrap angle and flatten and stabilize the strip, so that the slitting machine directly establishes tension with the coiler, and the aluminum coil is stretched after longitudinal slitting. The tensioning device is flattened and tensioned to ensure smooth separation of the strip and coiling. The strip is in tension during the entire slitting and slitting production process.

[0014] Such as figure 2 As shown, the slitting and slitting production line equipment for cold-rolled aluminum coils includes: coiler 1, steering roll 2, rear tensioning and fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com