Semi-automatic press for mechanical assembly

A semi-automatic and mechanical technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of personal injury of car drivers, inaccuracy, sudden quality accidents, etc., to eliminate hidden dangers of accidents, safe and convenient operation, The effect of improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

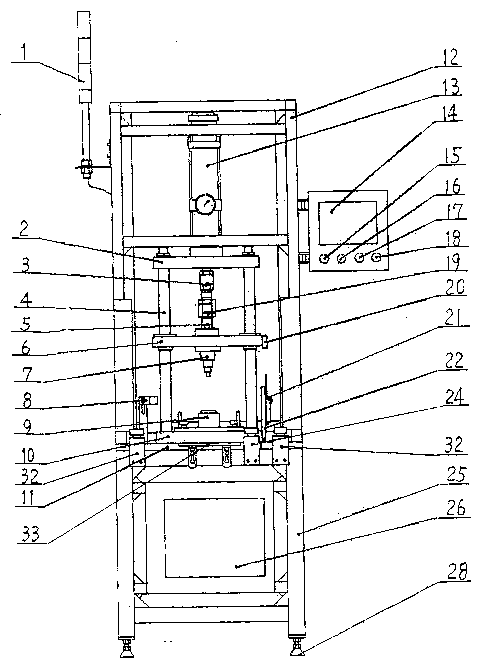

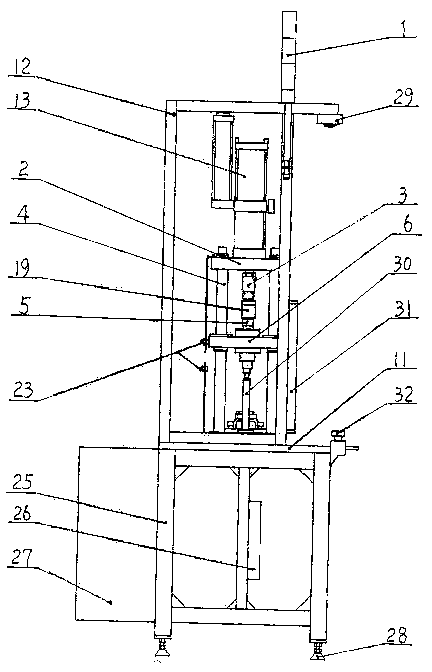

[0010] Examples, see attached figure 1 , 2 , The lower frame 25 of the mechanical assembly semi-automatic press is fixedly equipped with a pneumatic control system 26, an electrical control system 27, two start buttons 32, an emergency stop button 24, a bracket 33, and the bracket 33 is used to place the workpiece to be assembled. Adjustable feet 28 are respectively fixed on the lower end columns of the lower frame 25, and the upper end of the lower frame 25 is fixedly equipped with a work panel 11, and the work panel 11 is respectively fixed with a photoelectric switch 8, a safety limit column 30, and an upper frame 12. And four guiding optical shafts 4, four guiding optical shafts 4 are movable in the middle of a movable guide plate 6, the top is fixedly equipped with an upper fixed plate 2, and the lower end is fixedly equipped with a lower fixed plate 10, and the lower fixed plate 10 is fixedly placed on the On the work panel 11. The gas-liquid booster cylinder 13 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com