Separated-type slide block mechanism with flicking needle

A separate, sliding block technology, applied in the field of hardware processing, can solve the problems of hardware surface coating scratches, product quality decline, hardware deformation, etc., and achieve low machine power requirements, reduced mold size, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

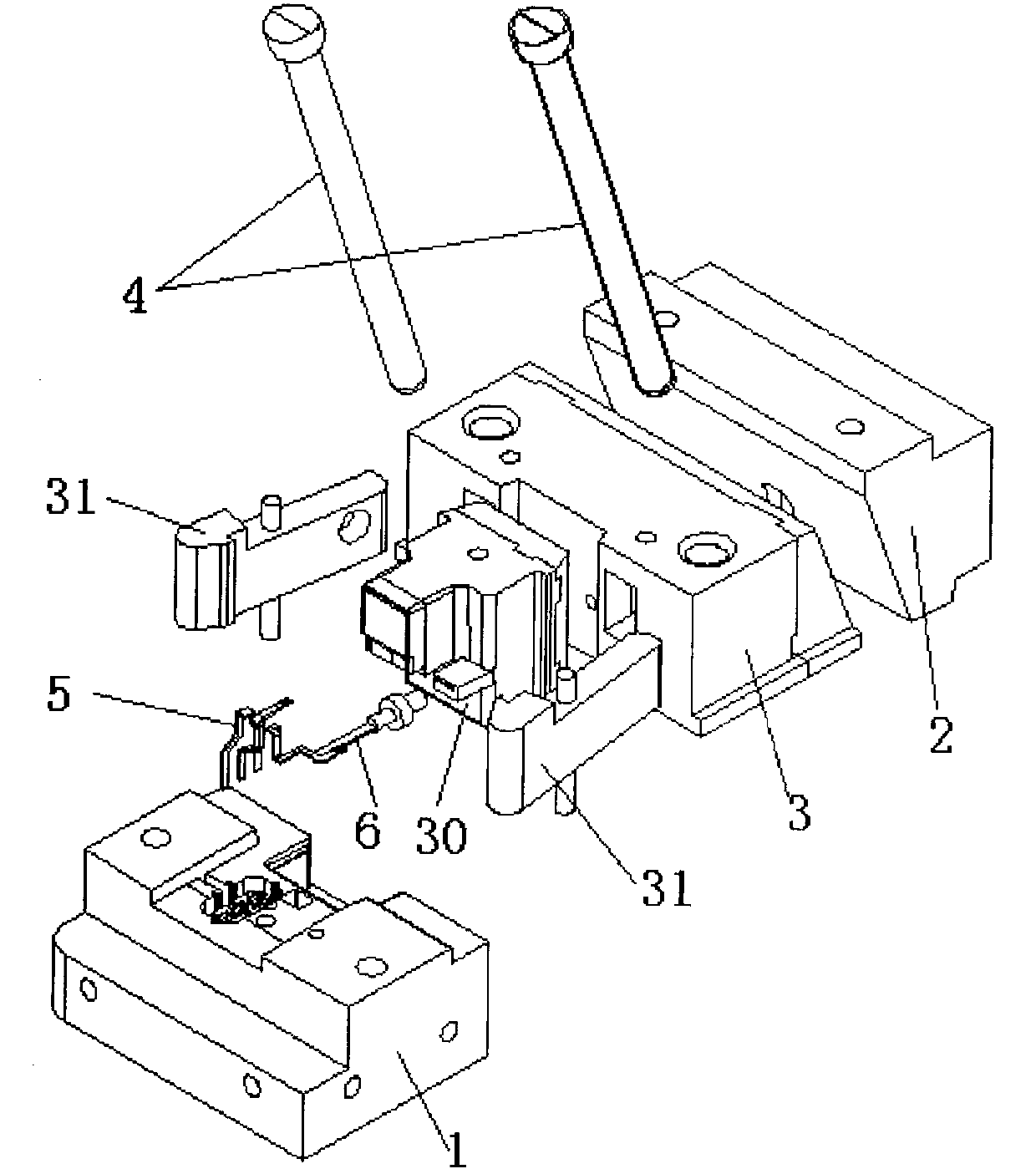

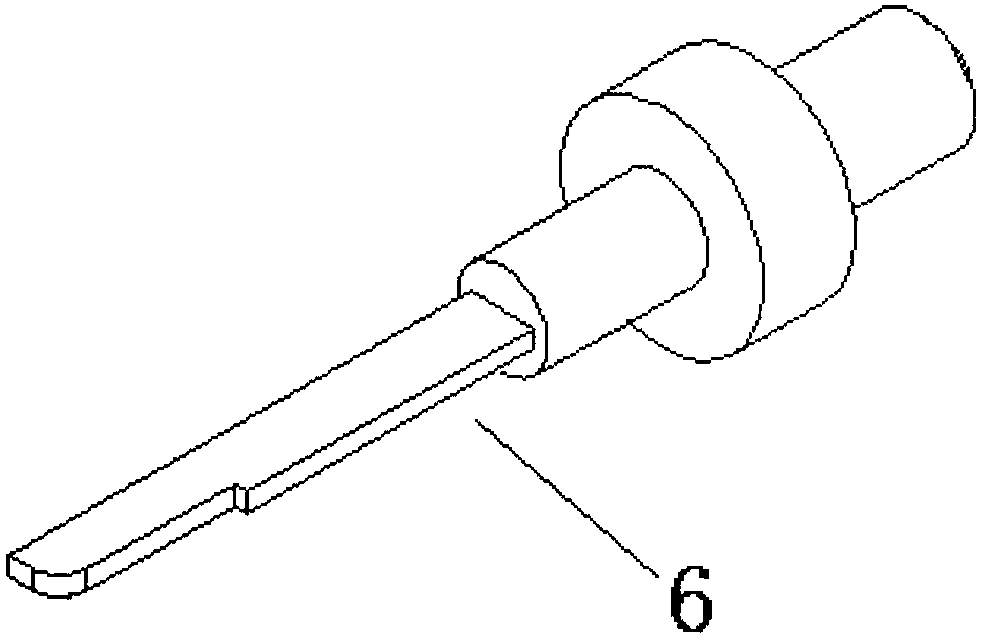

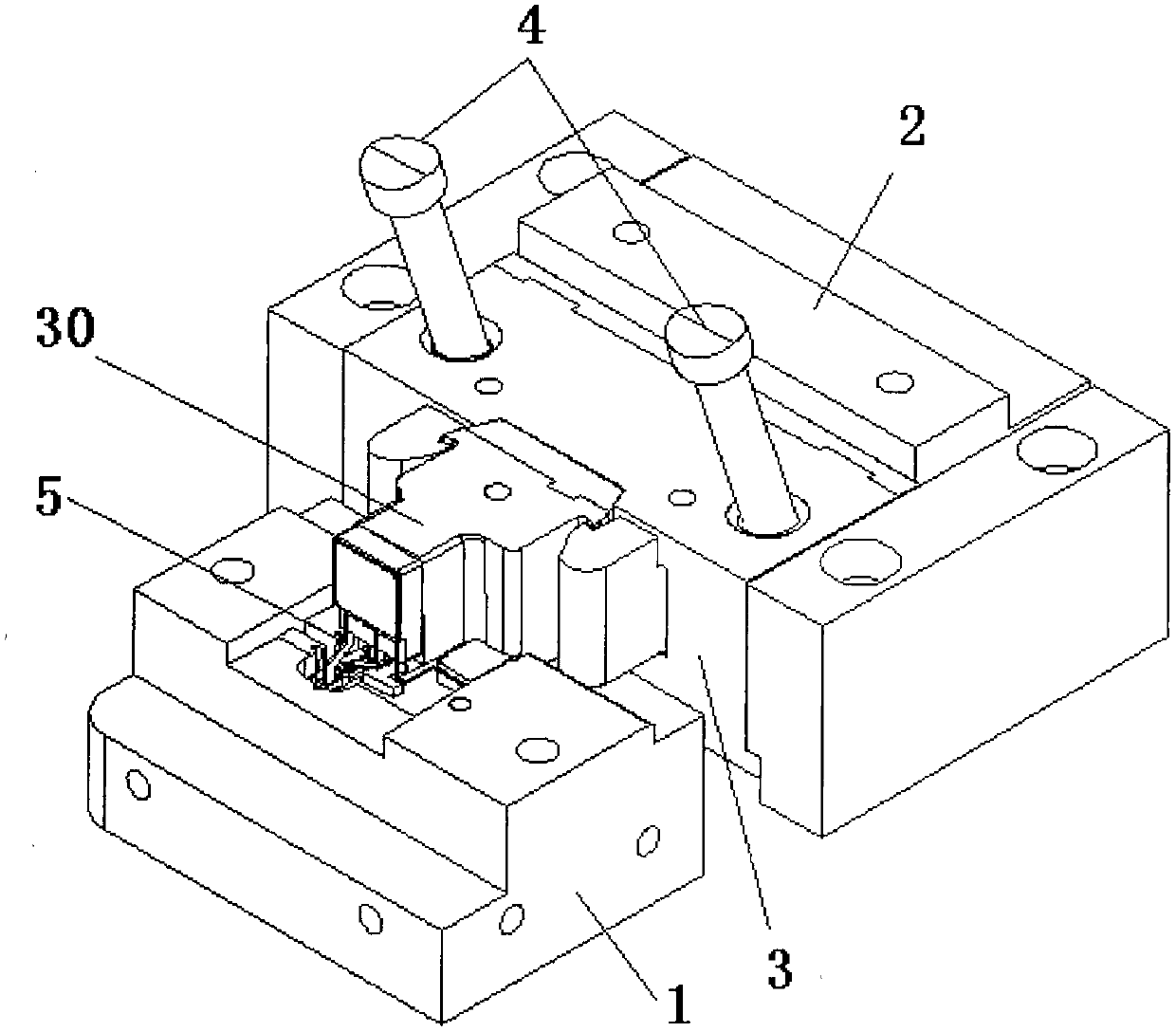

[0014] see figure 1 , the embodiment of the present invention includes: a separate slider mechanism with spring pins, including: a rear mold core 1, a shovel 2, a slider seat 3 and two inclined guide posts 4, and the two inclined guide posts 4 respectively pass through Through the oblique holes at both ends of the slider base 3, the shovel 2 is locked behind the slider base 3, a slider 30 and a pull hook 31 are arranged directly in front of the slider base 3, and the pull hooks 31 are distributed on both sides of the slider 30 , the hardware component 5 is installed on the slider 30, and the middle part of the inner cavity of the slider 30 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com