external gear pair

A technology of external gears and gear pairs, which is applied to gear transmissions, belts/chains/gears, components with teeth, etc. It can solve the problem of fewer design parameters, achieve enhanced transmission performance and sealing function, and is beneficial to processing and testing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

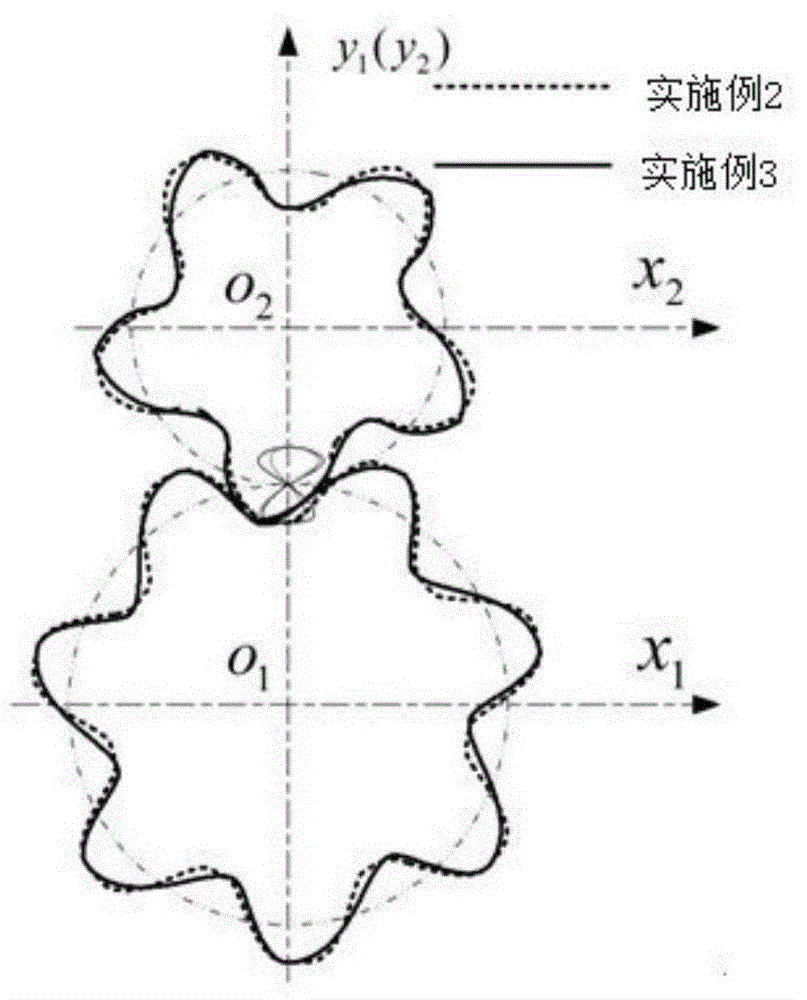

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

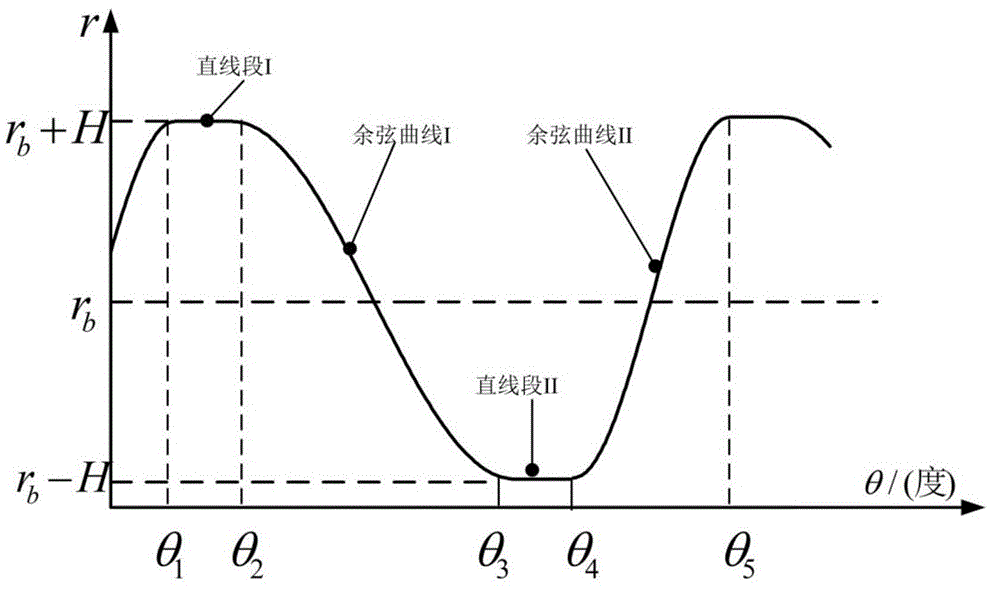

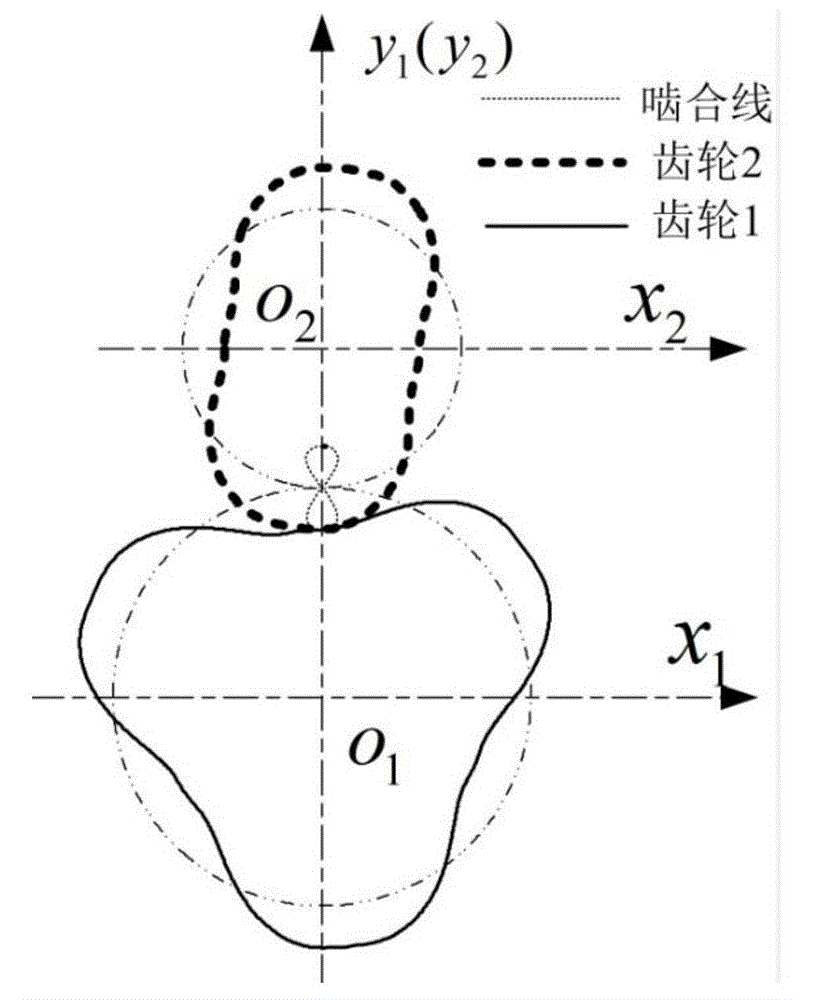

[0046] The external meshing gear pair of the present invention, the single tooth profile of the external gear I is composed of a cosine-based compound curve that satisfies the first-order continuous straight line segment I, cosine curve I, straight line segment II and cosine curve II in polar coordinates, and the external gear I The single conjugate tooth profile of the external gear II corresponding to the single tooth profile is obtained through the meshing principle to form a conjugate gear pair; the complete conjugate gear pair is the single tooth profile of the external gear I and the external gear II respectively around its center according to the number of teeth. Cloth gets.

[0047]The design method of the external meshing gear pair of the present invention: first determine the single tooth profile of the external gear I in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com