Tubular heat exchanger structure provided with vibrating heat-conducting pieces

A technology of tubular heat exchangers and heat conducting fins, which can be used in vibration cleaning, cleaning heat transfer devices, lighting and heating equipment, etc., and can solve problems such as scaling and affecting heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

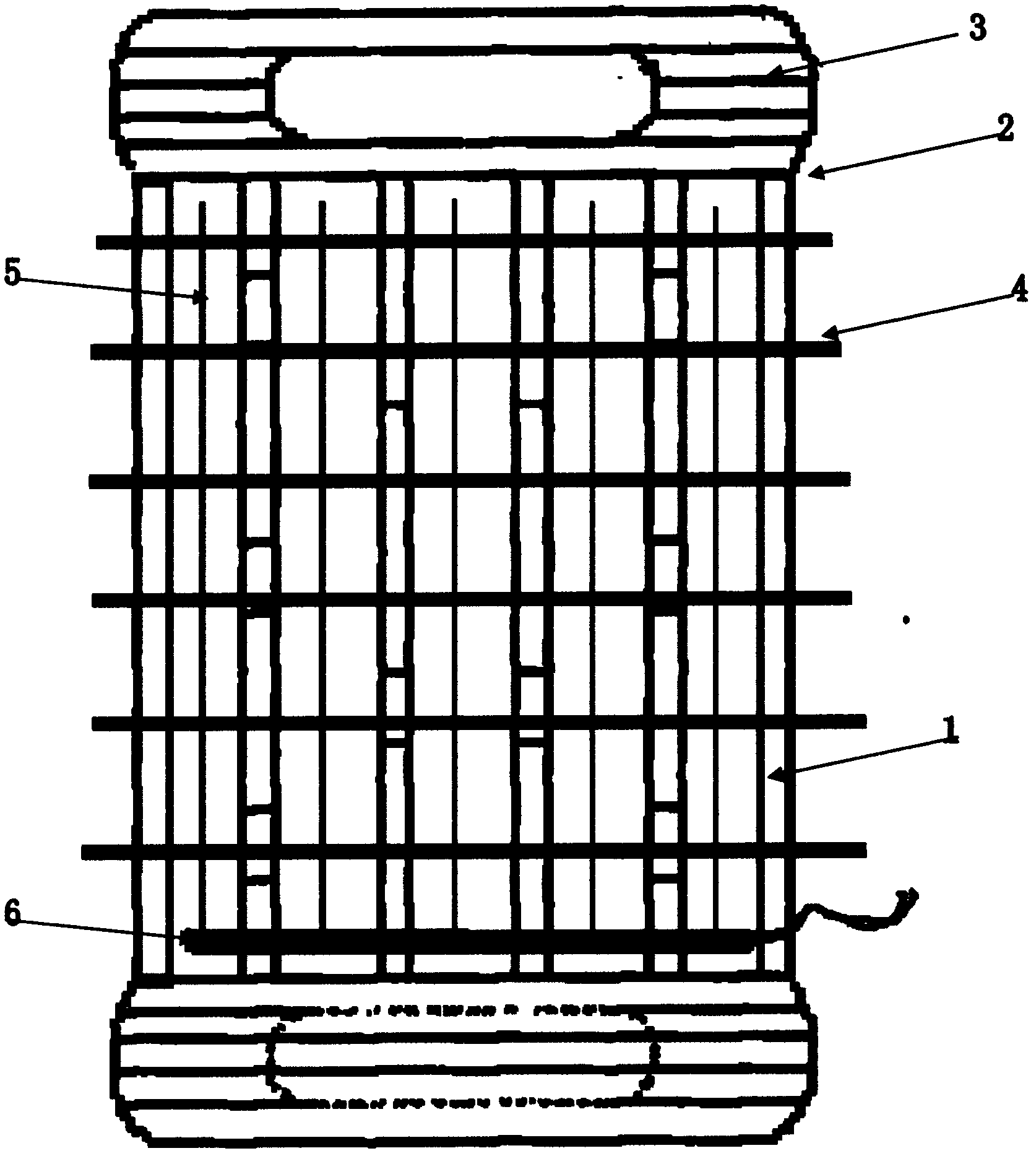

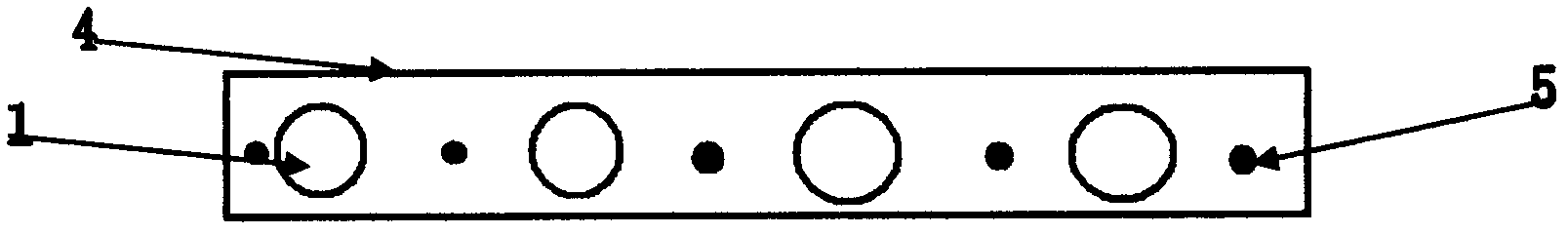

[0009] as attached figure 1 , 2 As shown, first of all, the present invention is the same as the ordinary heat exchanger, and the heat exchange tubes (1) are arranged densely in the form of display, and the heat exchange tubes (1) are arranged with tube plates at both ends of the display. (2) and the heat exchange cavity (3), the heat transfer medium enters and exits the heat exchange tube (1) from the heat exchange cavity (3); then, a heat exchange fin (4) is arranged on the heat exchange tube (1), and the The heat exchange fins (4) are penetrated by the heat exchange tubes (1), that is, the heat exchange fins (4) are densely opened, and each aperture surrounds each heat exchange tube (1) and is in close contact with them, but not fixed; finally, each heat exchange fin (4) is provided with a vibrating prop (5), and the vibrating prop (5) is connected with a vibrating device (6), and the vibrating device (6) can be driven by a motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com