Grain mass measurement device and measurement method of combine harvester

A combine harvester and quality measurement technology, applied in the field of sensors, can solve the problems of low grain measurement accuracy and small size, and achieve low cost, improved measurement accuracy, and simple and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

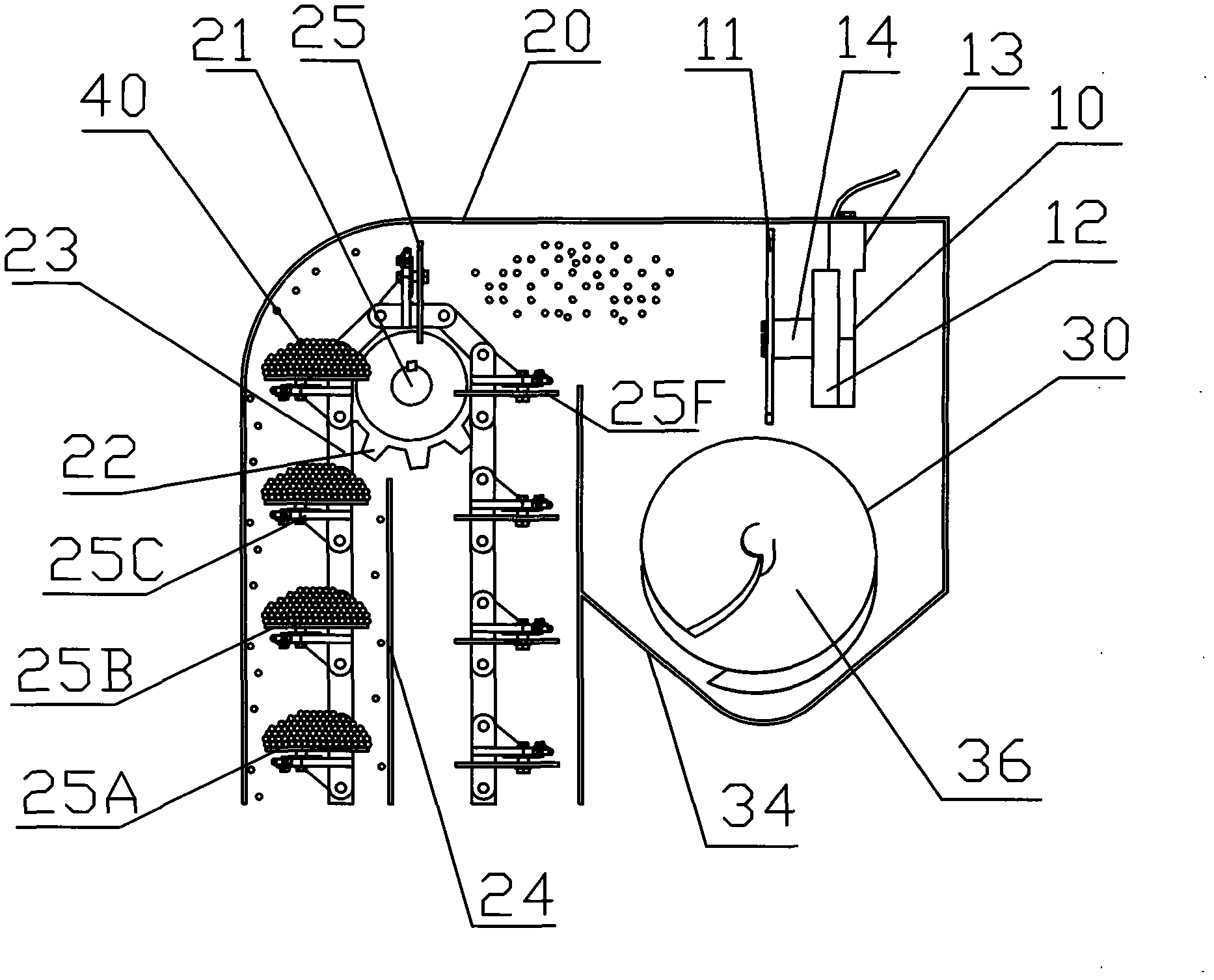

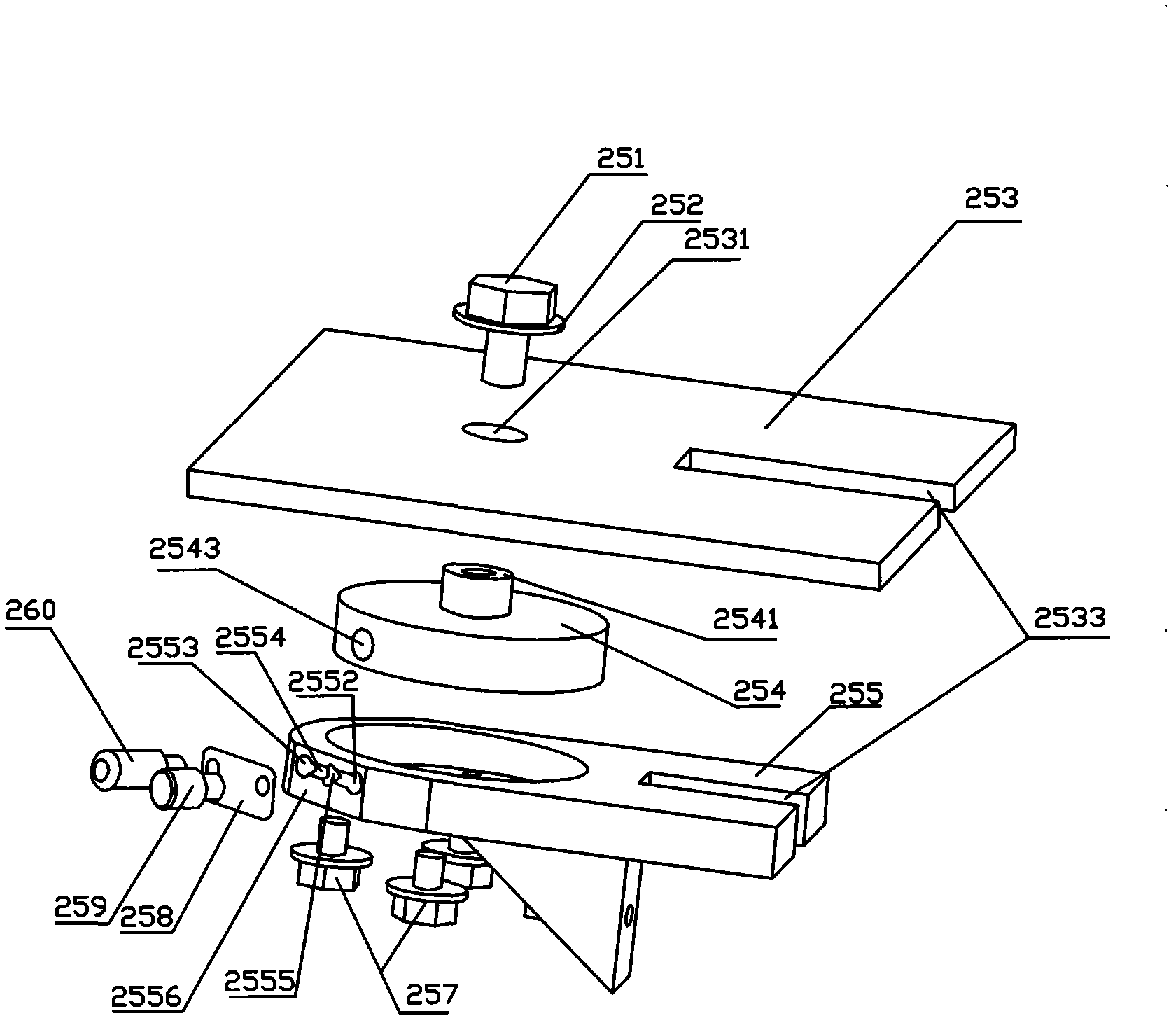

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

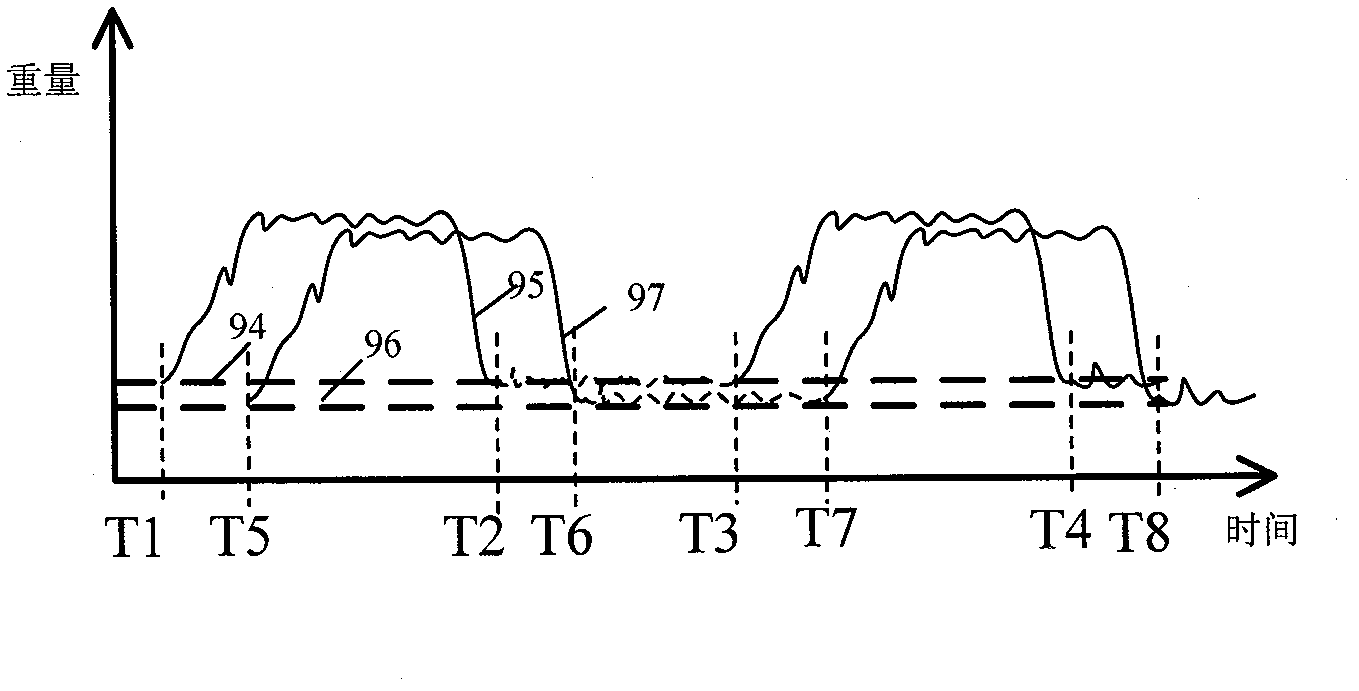

[0039] like figure 1 As shown, a grain quality measuring device of a combine harvester includes a net beam lifting device 20 installed on the combine harvester, a multi-dimensional grain mass flow sensor 10 fixed on the outside of the net grain lifting device 20 and a net beam lifting device 20 inside Located in the grain collection area 30 below the multi-dimensional grain flow sensor 10, the net beam lifter 20 is divided into two compartment units by a partition 24;

[0040] The collection area includes a charging screw 36, an inclined surface 34 located at the left side and the bottom of the charging screw 36, the charging screw 36 faces the storage container for collecting grain, and the charging screw 36 transports the grain from the collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com