Scraper with filtering cake braking device

A crushing device and scraper technology, applied in the centrifuge and other directions, can solve the problem that the filter cake layer cannot be automatically removed, and achieve the effect of reducing labor intensity and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

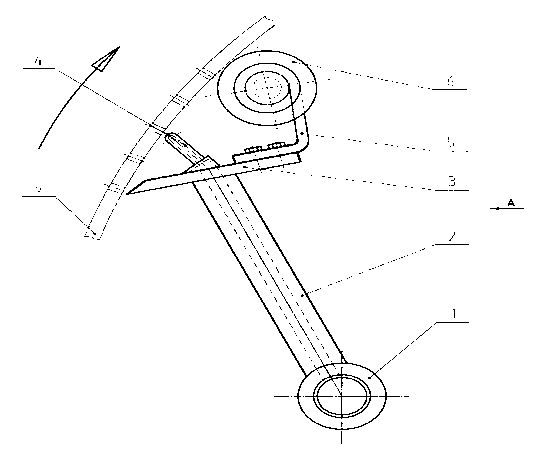

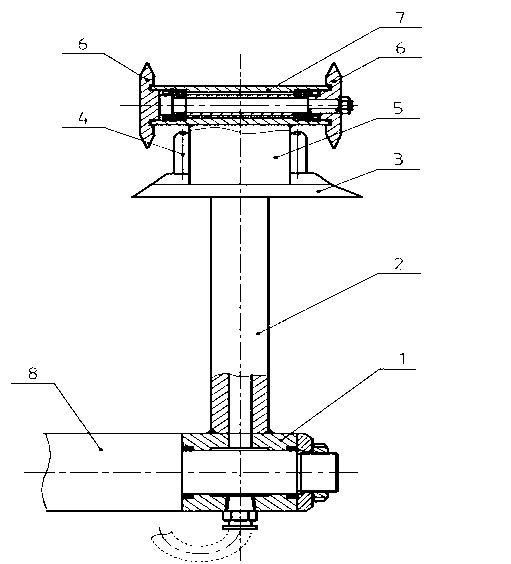

[0011] Depend on figure 1 , 2 It can be seen that the scraper with a filter cake crushing device includes a connecting sleeve 1, a scraper rod 2, a scraper blade 3, an air blow nozzle 4, a bracket 5, a roller 6, and a mounting seat 7. The two ends of the scraper rod 2 are respectively connected to the scraper blade 3 It is connected with the connection sleeve 1, and the tail of the scraper blade 3 is equipped with a bracket 6, and one end of the bracket 6 is connected with a mounting seat 7, and an air blowing nozzle 4 is arranged on the outside of the scraper blade 3, and rollers 6 are installed at both ends of the mounting seat 7, and the bracket 5 is on the scraper blade. The position on the sheet 3 is adjustable, and an air inlet is arranged in the middle of the scraper bar 2 .

[0012] When the scraper with filter cake crushing device of the present invention is working, the drum 9 rotates at a low speed in the direction of the arrow in the diagram, the cylinder shaft 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com