Screw withdrawal tool

A technology for removing tools and screws, which is applied in the direction of manufacturing tools, wrenches, wrenches, etc., and can solve problems such as slippage and large gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

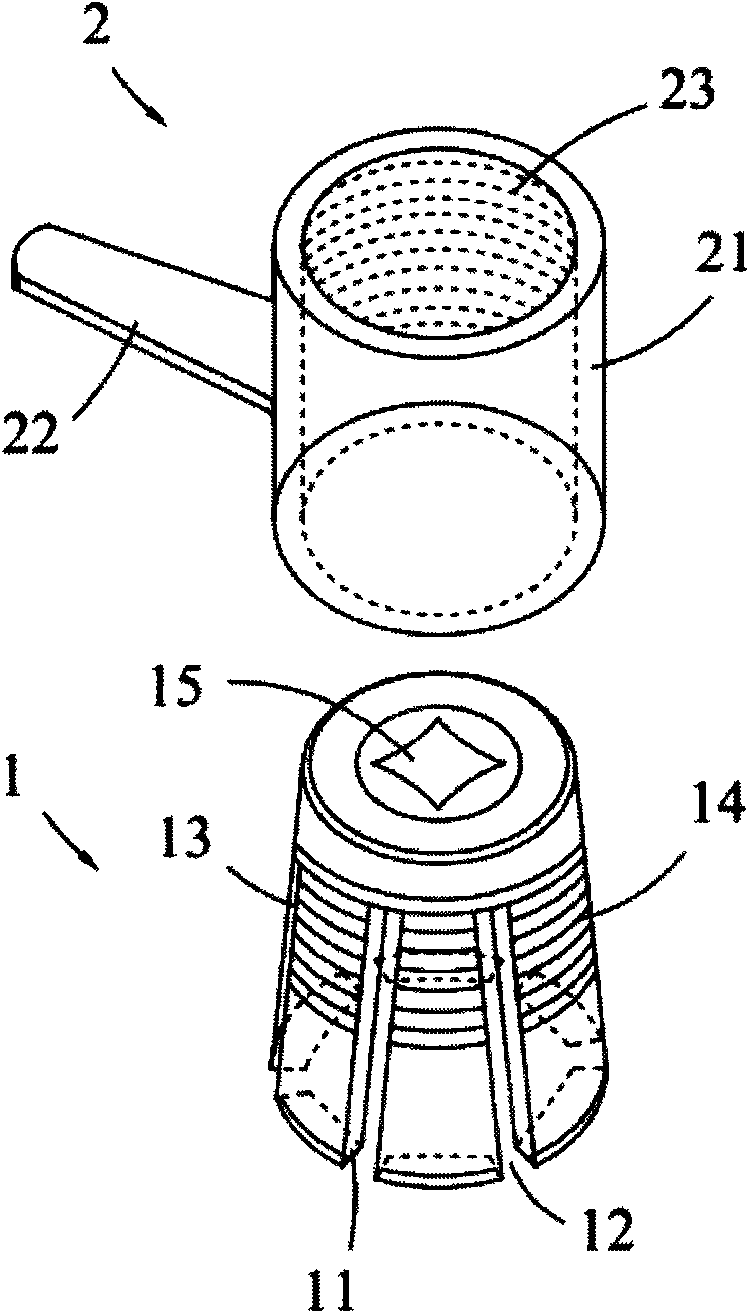

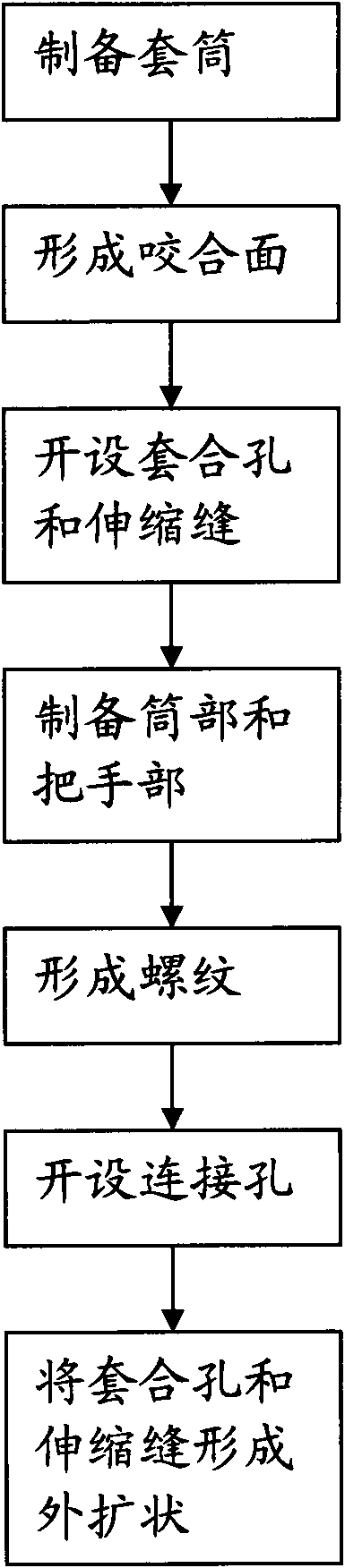

[0013] See figure 1 , a screw removal tool, including a fastening sleeve 1 and a compression rotating part 2 sleeved on the fastening sleeve 1, the inner side of one end (lower part) of the fastening sleeve 1 is provided with a hexagonal occlusal surface in section 11. Its cross-sectional shape can also be other shapes. The principle is that the more the better, the finer the better, but considering the manufacturability and application, so in this embodiment, its cross-section is hexagonal, and in order to increase its friction force, and its surface can also be covered with small teeth (not shown), the other end (upper) of the fastening sleeve 1 is provided with a connection hole 15, the cross section of the connection hole 15 is quadrangular, and can also be other shapes, its main The purpose is to insert other connecting tools into the connecting hole 15 when the rotary member 2 cannot be rotated and pressed, and the device is rotated to assemble / disassemble the screws. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com