Welding method of polyethylene (PE) gas valve

A welding method and gas valve technology are applied in the field of welding, which can solve the problems affecting the installation of matching vent pipes, large size deviation, etc., and achieve the effects of ensuring the quality of welding seams, improving welding efficiency, and ensuring the consistency of installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

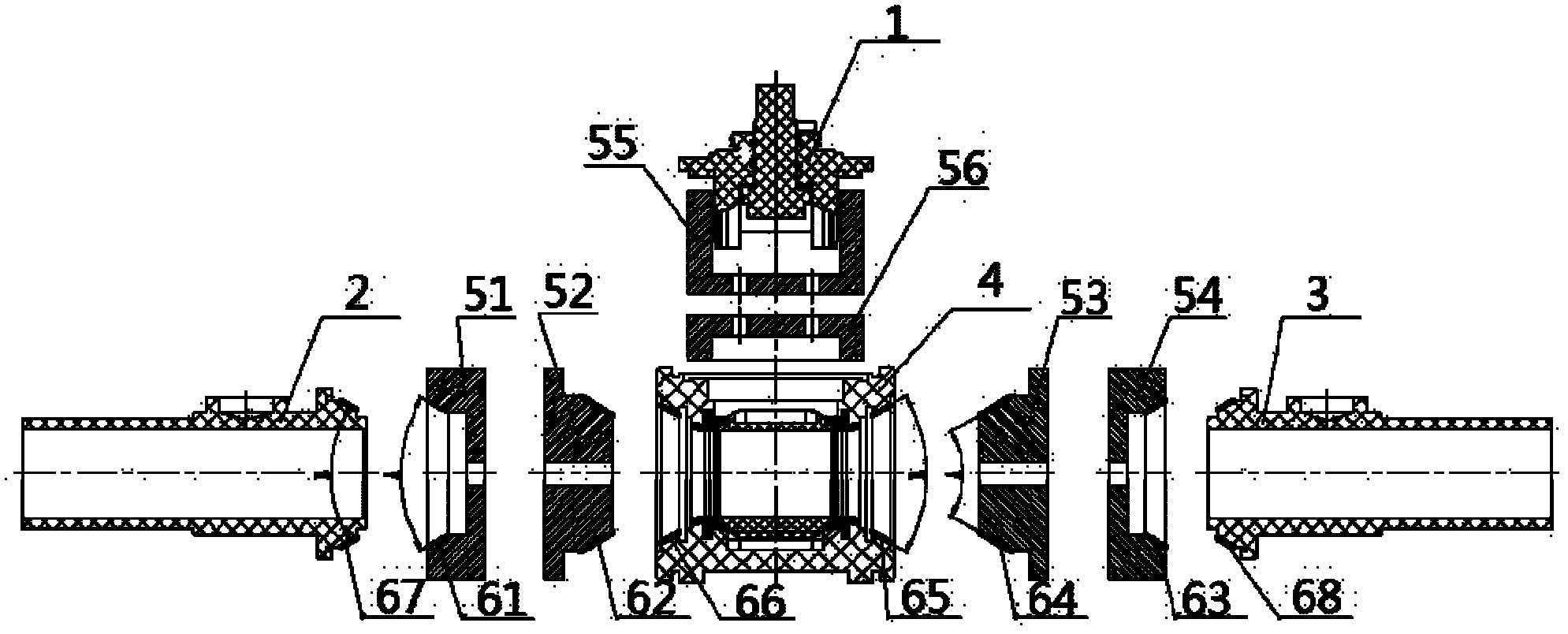

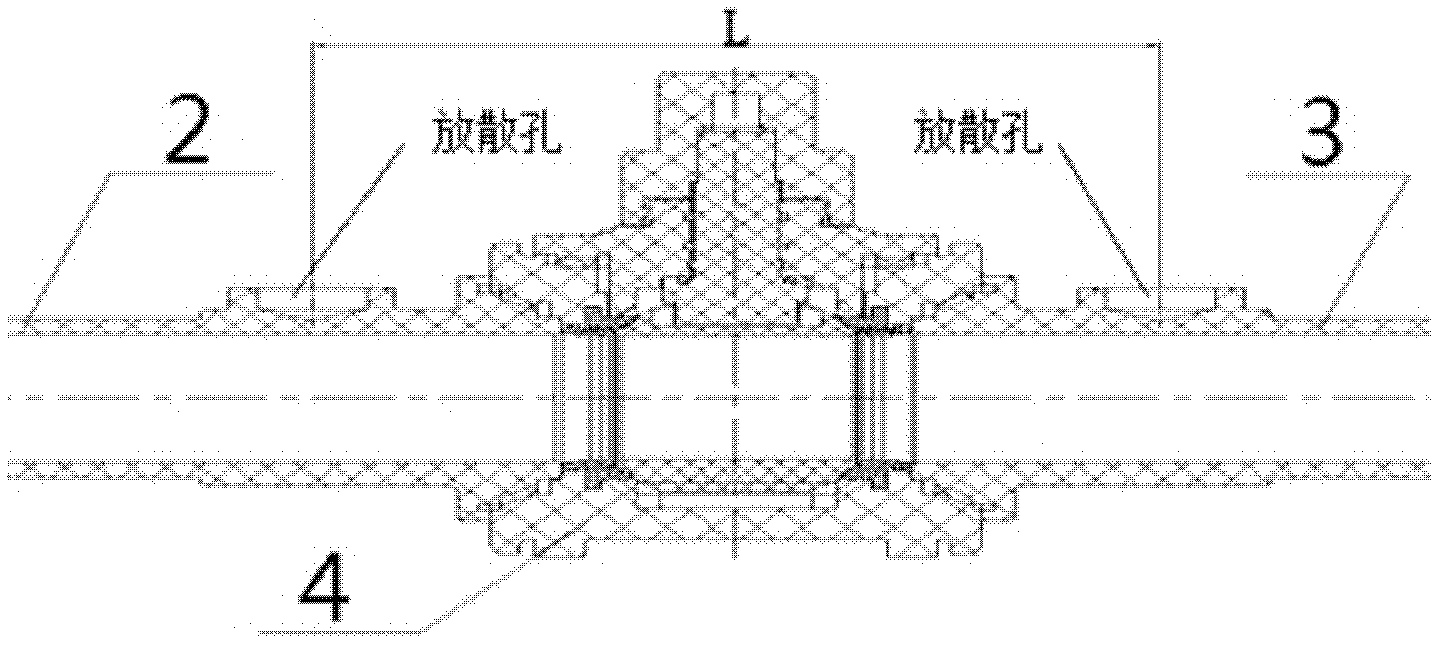

[0010] Such as figure 1 , figure 2 As shown, the welding hot molds 51, 52, 53, 54 are made into conical surfaces like the welding surfaces of the end pipe assemblies 2 and 3, and the angle of the conical surfaces is consistent with the angle of the welding surface of the welding components. Adhesion, Teflon coating on the surface of the welding hot mold; the welding hot mold executes the program setting action at the left, right and upper ends of the welding machine at the same time, and the welding hot mold welding surfaces 61, 62, 63, 64 and the end pipe assembly The welding surfaces 67, 68 and the valve body assembly 4 welding surfaces 66, 65 are bonded, the welding surfaces of the welding hot molds 55, 56 are bonded to the valve upper seat assembly 1 welding surface, and the valve body assembly welding surface, and mechanical limit is adopted during hot melting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com