Crawler crane mast lifting hydraulic control system and method

A technology of crawler cranes and adjustment systems, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of dependence on sensor data, high labor intensity, hidden safety hazards, etc., achieve simple pipeline layout, reduce work intensity, and avoid accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

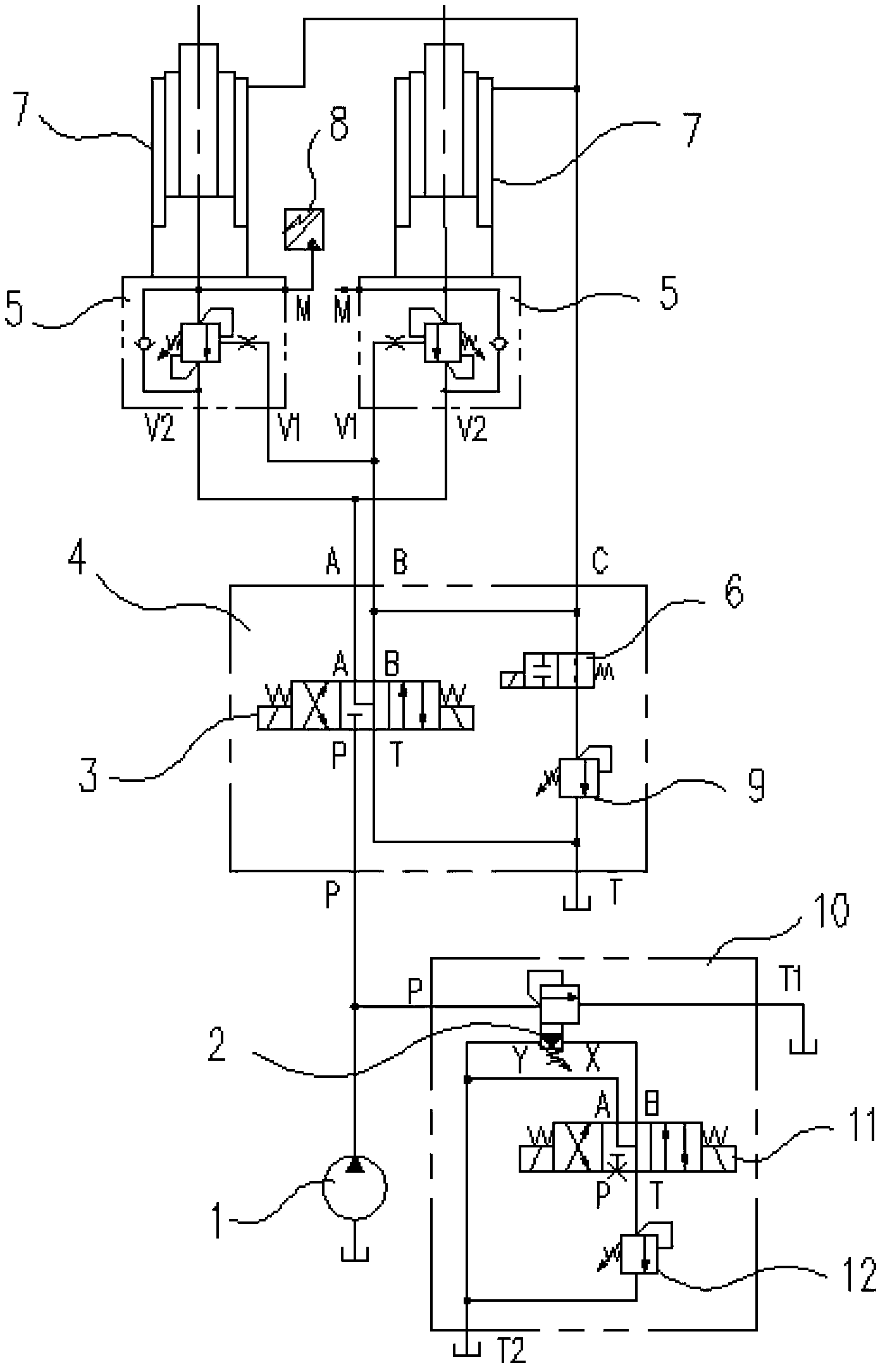

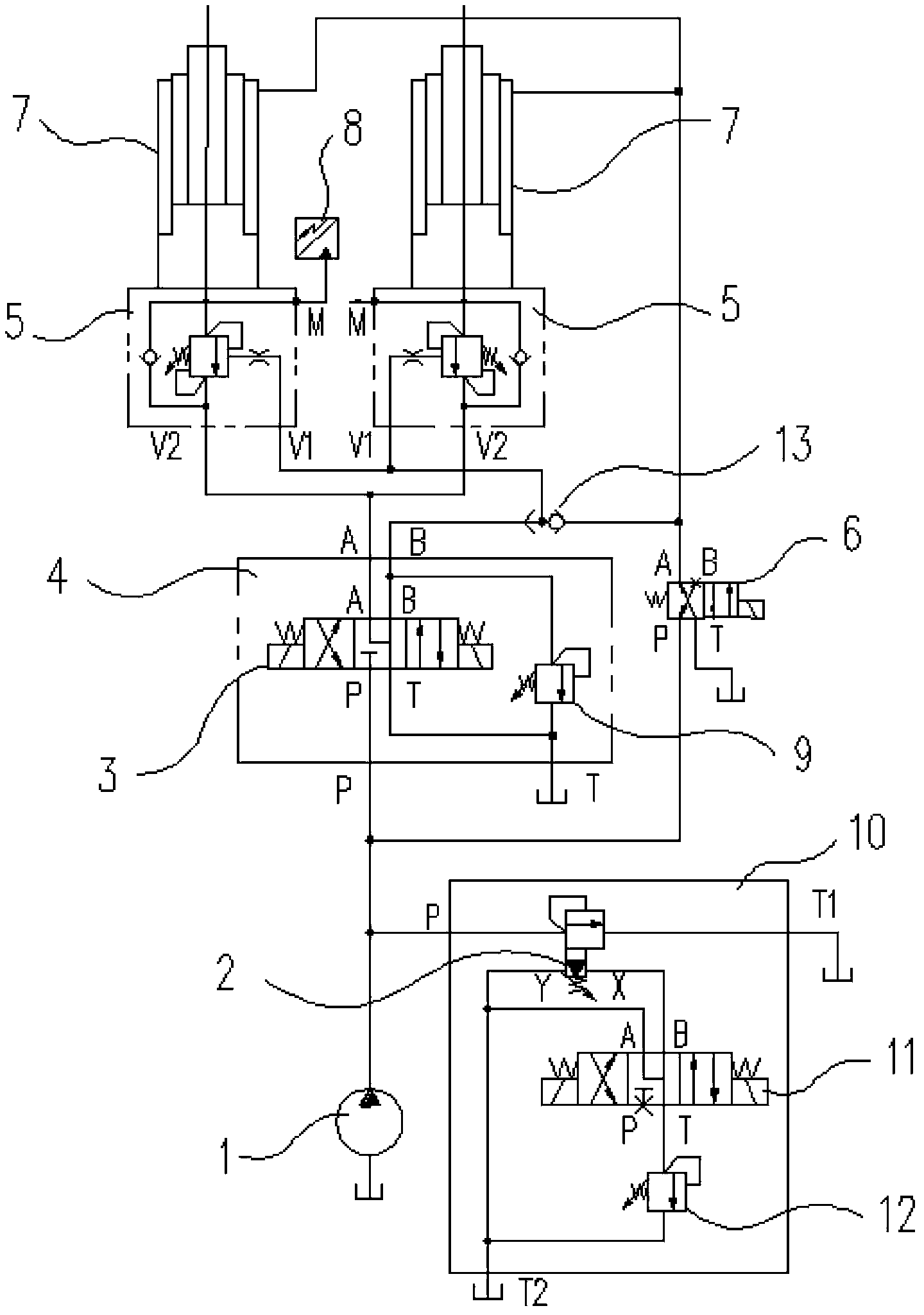

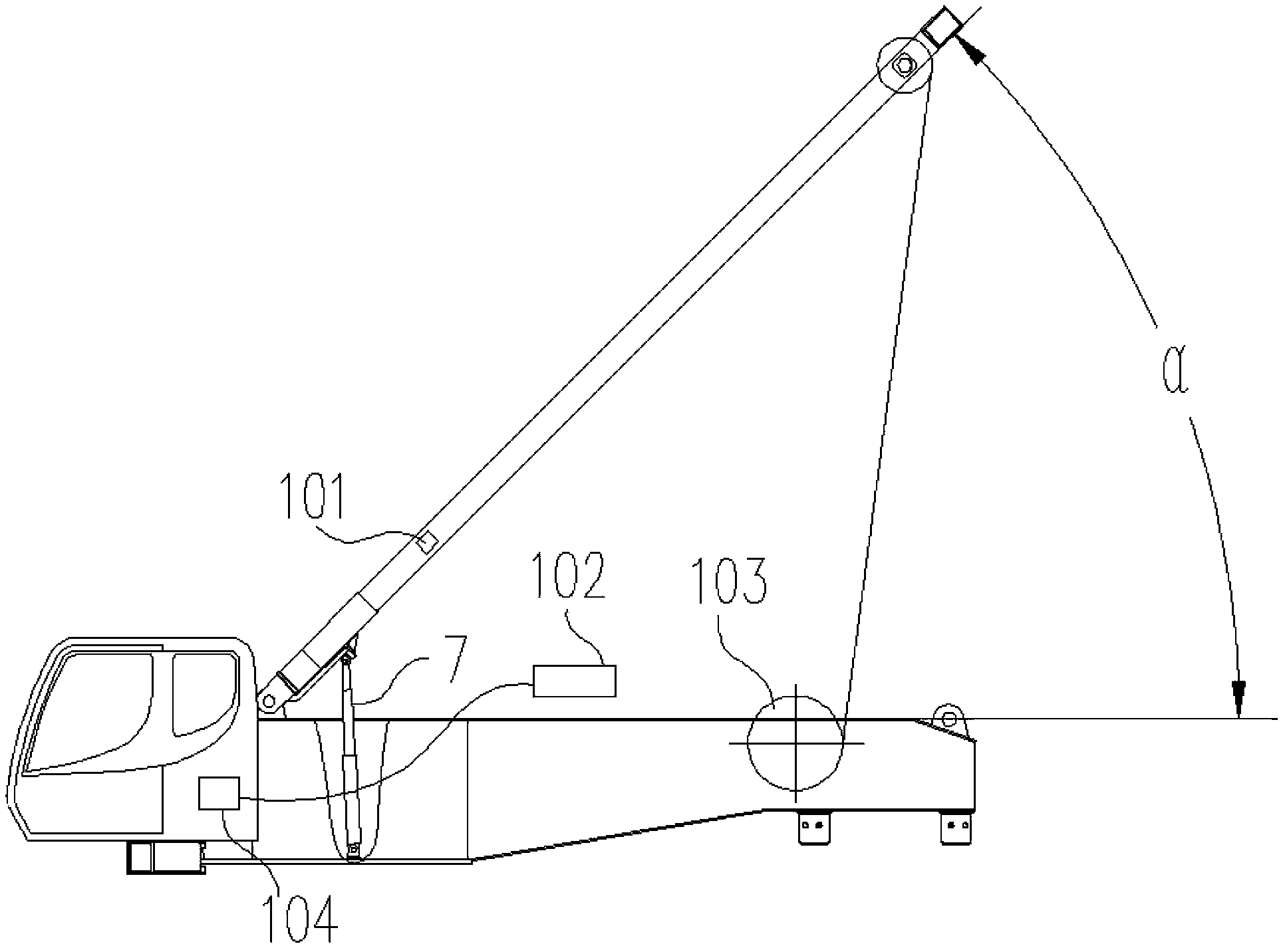

[0041] Such as figure 1 with 3 As shown, the crawler crane mast lift control hydraulic adjustment system consists of a jacking cylinder 7, a balance valve 5, a main reversing module 4, a pump pressure regulating module 10, a hydraulic pump 1, a pressure sensor 8, an angle sensor 101, and a main luffing coil Yang control system 103, controller 104, and control switch 102 are composed of:

[0042] The jacking cylinder 7 adopts a two-stage oil cylinder, and the balance valve 5 is directly fixed on the connection block where the 7 large chambers of the jacking cylinder are located, and a pressure sensor 8 is installed at the oil port M directly connected with the large chamber of the oil cylinder on the balance valve 5 .

[0043] The balance valve 5 adopts a single-acting balance valve, specifically: the hydraulic oil flows through the balance valve 5 to the large chamber of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com