Two stage decomposition process method of Bayer process alumina production

A technology of alumina and Bayer method, which is applied in the direction of alumina/aluminum hydroxide, can solve the problems of aluminum hydroxide crystal growth, aluminum hydroxide crystal cracking and abrasion, etc., to achieve improved particle size and strength, good economic benefits, The effect of a good sale price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

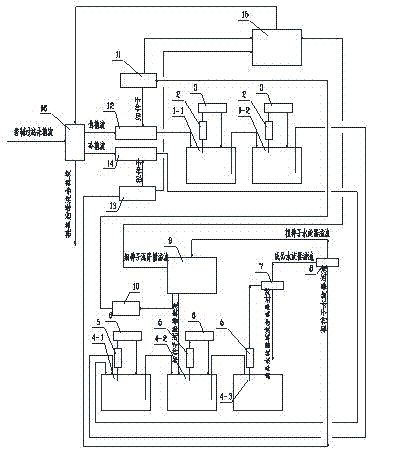

[0022] Embodiment one: as attached figure 1 As shown, the semen filtered out from the control is divided into two paths through the plate heat exchanger for heat exchange, a part (30%) is heated at 80°C after heat exchange through the plate heat exchanger, and becomes hot semen, and the other part (70%) %) control the temperature after heat exchange at 65°C to become cold semen; the hot semen and the filter cake of the fine seed filter 11 are mixed in the fine seed seed tank 12 to become fine seed slurry, and the temperature of the mixed slurry is controlled At about 77°C, with a solid content of 150g / l, the seeds are pumped to the decomposition tank 1 of the agglomeration section for agglomeration; the cold semen is mixed with the filter cake of the coarse seed filter 13 in the coarse seed crystal tank 14 to form Coarse seed slurry, the mixed slurry temperature is controlled at 62°C, with a solid content of 450g / l, and is pumped to the first tank 4 of the decomposed growth se...

Embodiment 2

[0024] Embodiment two: as attached figure 1 As shown, the semen filtered out from the control is divided into two paths for heat exchange through the plate heat exchanger, and a part (35%) becomes hot semen at a temperature of 76°C after heat exchange through the plate heat exchanger, and the other part (65%) ) control the temperature after the heat exchange at 62°C to become cold semen, and the hot semen and the filter cake of the fine seed filter 11 are mixed in the fine seed crystal seed tank 12 to become fine seed slurry, and the temperature of the mixed slurry is controlled at At about 75°C, with a solid content of 120g / l, it is pumped to the decomposition tank 1 of the agglomeration section through the seed crystal for agglomeration; the cold semen is mixed with the filter cake of the coarse seed filter 13 in the coarse seed crystal tank 14 to form a coarse semen For the seed slurry, the temperature of the mixed slurry is controlled at 60° C., and the solid content is 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com