Method for preprocessing furnace temperature distribution data of scrap copper smelting furnace

A technology of temperature and distribution data in a furnace, applied in electric furnaces, crucible furnaces, rotary drum furnaces, etc., can solve the problems of slow running of the processor, occupying the memory space of the processor, and many time points of the temperature distribution data. The effect of reducing the amount of storage, running smoothly, and freeing up memory space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] A method for preprocessing temperature distribution data in a scrap copper smelting furnace, specifically comprising the following steps:

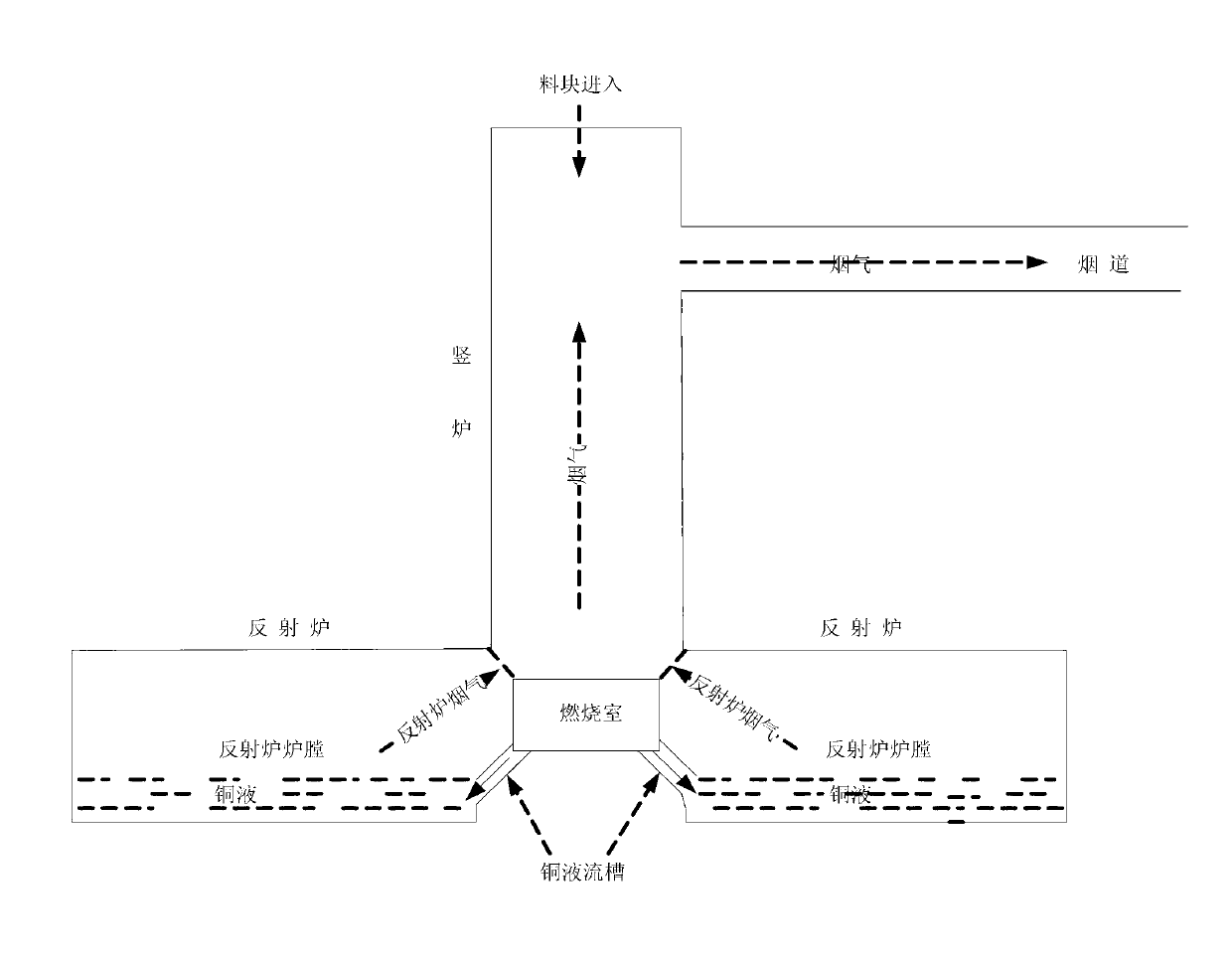

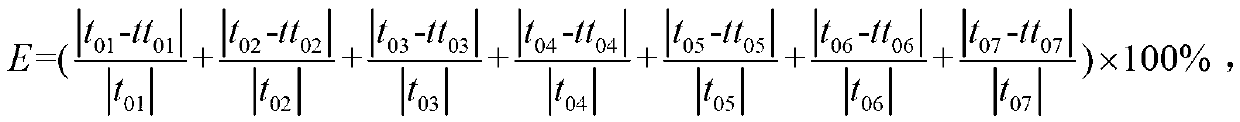

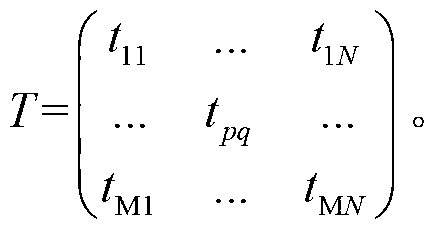

[0019] (1) Establish a fluid dynamics simulation calculation simulation model for the temperature in the smelting furnace. Firstly, use the grid drawing software (Gambit) to draw the 3D grid model of the smelting furnace; then import the 3D grid model into the fluid dynamics simulation calculation (CFD) simulation software (Fluent); set various working conditions for the simulation application, including The flow and pressure of natural gas at the front of the shaft furnace and its corresponding combustion air flow and pressure, the flow and pressure of natural gas at the rear of the shaft furnace and its corresponding combustion air flow and pressure, the composition of natural gas, reflection The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com