The method of using frp bars to replace steel mesh sheets

A technology of steel mesh and reinforcement mesh, which is applied in the field of replacing steel mesh with FRP bars, can solve the problems of increasing maintenance costs, and the structural durability cannot be guaranteed, and achieves the effect of large specific modulus and high specific strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

[0028] combine figure 1 and figure 2 Shown, the present invention utilizes FRP bar to replace the method for steel mesh sheet, and its steps comprise:

[0029] Determine the physical parameters of the steel mesh to be replaced: diameter Ds, spacing Ss in two directions, number of roots NS and modulus Es;

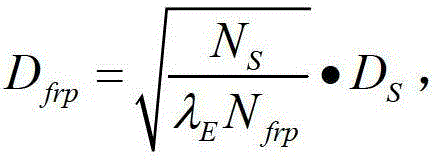

[0030] Select the FRP bar and determine its modulus E frp ; And set its physical parameters: the diameter is D frp , the spacing is S frp , root number N frp and modulus E frp ;

[0031] The stiffness of the steel mesh in the same direction before and after being replaced by the FRP mesh must be equal, that is, the section stiffness Ks of all steel bars in the same direction = EsAs and the section stiffness K of all FRP bars in the same direction frp =E frp A frp Equal, Es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com