Mud sand pump impeller provided with supra polymer weight polyethylene protection layer

An ultra-high molecular weight, polyethylene technology, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids, which can solve the problems of limited service life and large wear of mud sand pumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

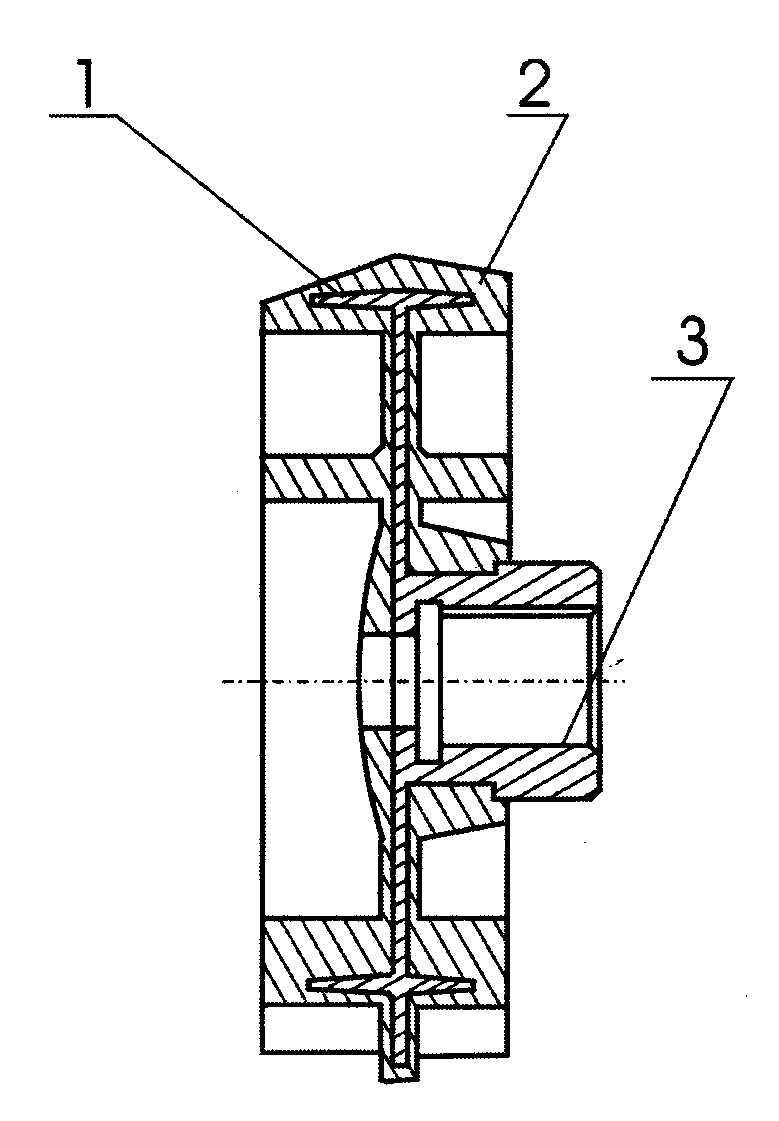

[0012] Combine below figure 1 The present invention is further described:

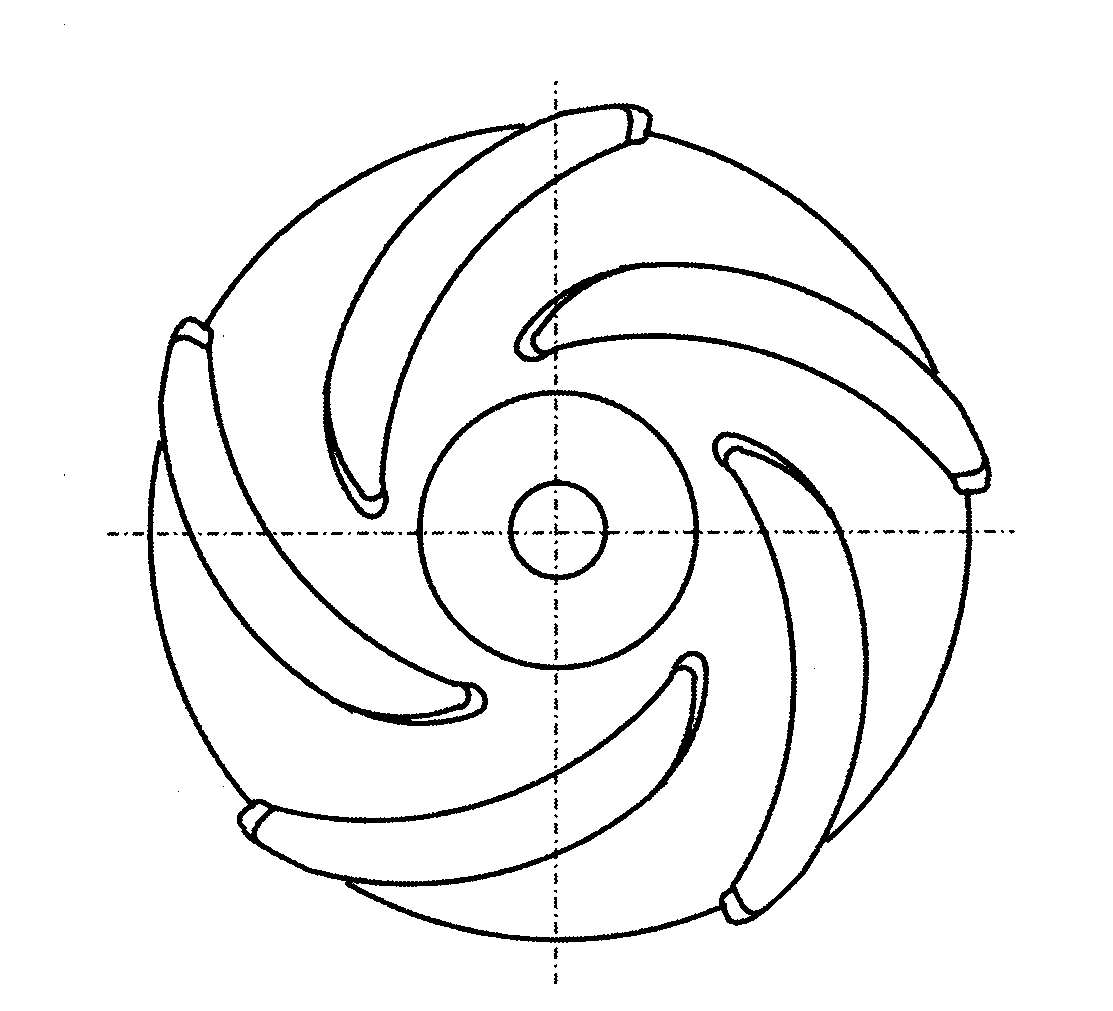

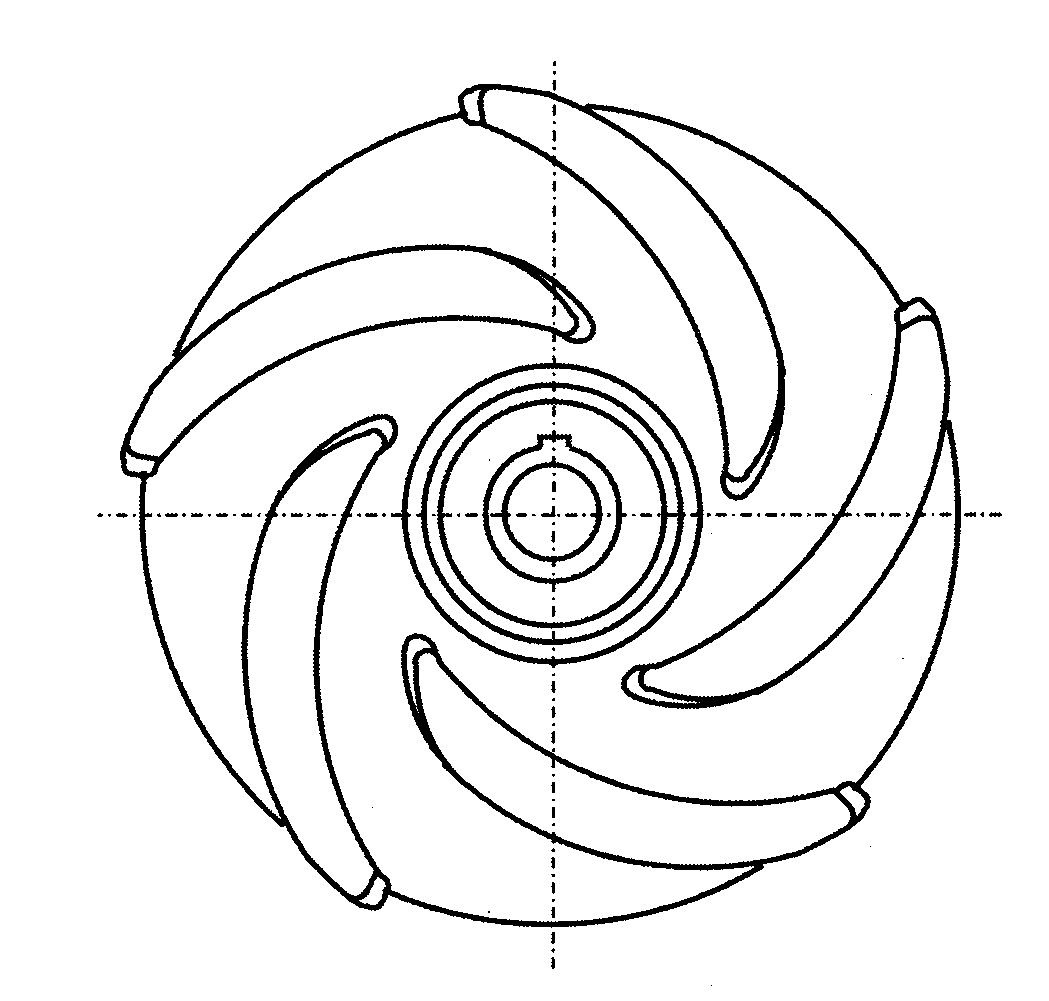

[0013] On the inner frame 1 of the impeller of the ferrous sand pump impeller, process the part 3 that cooperates with other parts of the mud pump according to the technical requirements, and wrap the ultra-high molecular weight polyethylene material on the inner frame 1 of the impeller of the black metal mud pump by molding to form a super High molecular weight polyethylene material mud sand pump impeller cladding layer 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com