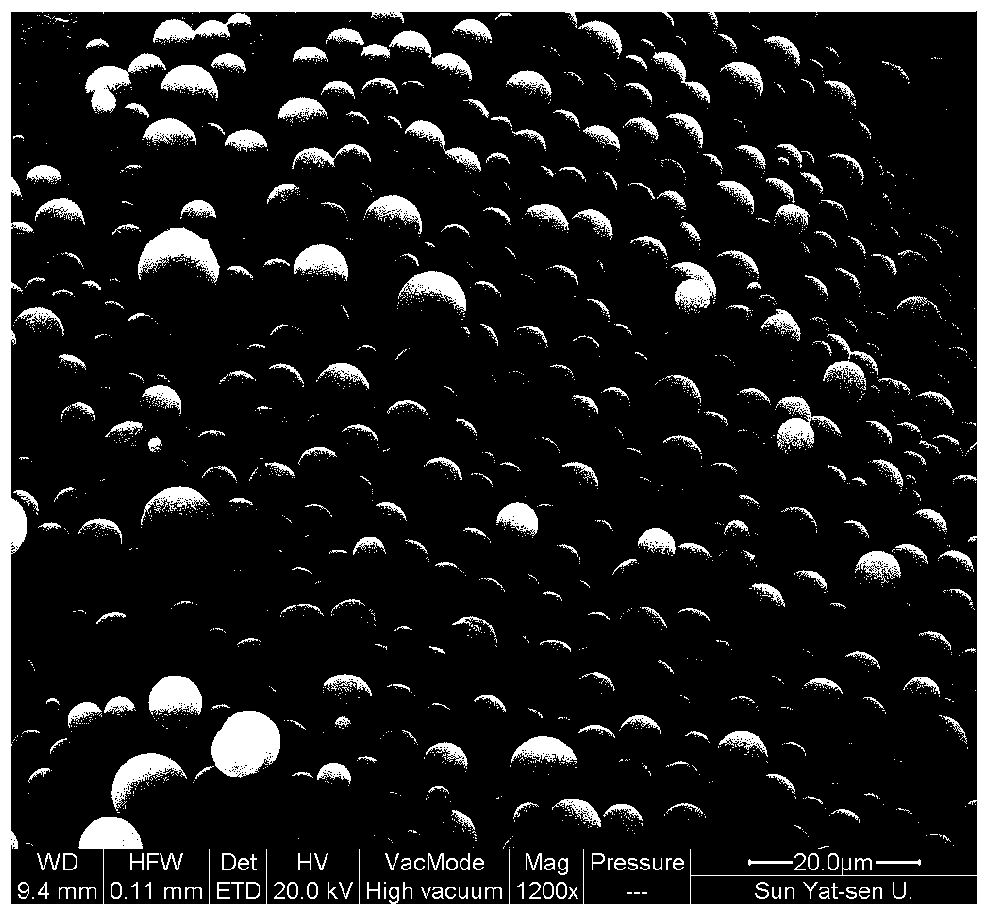

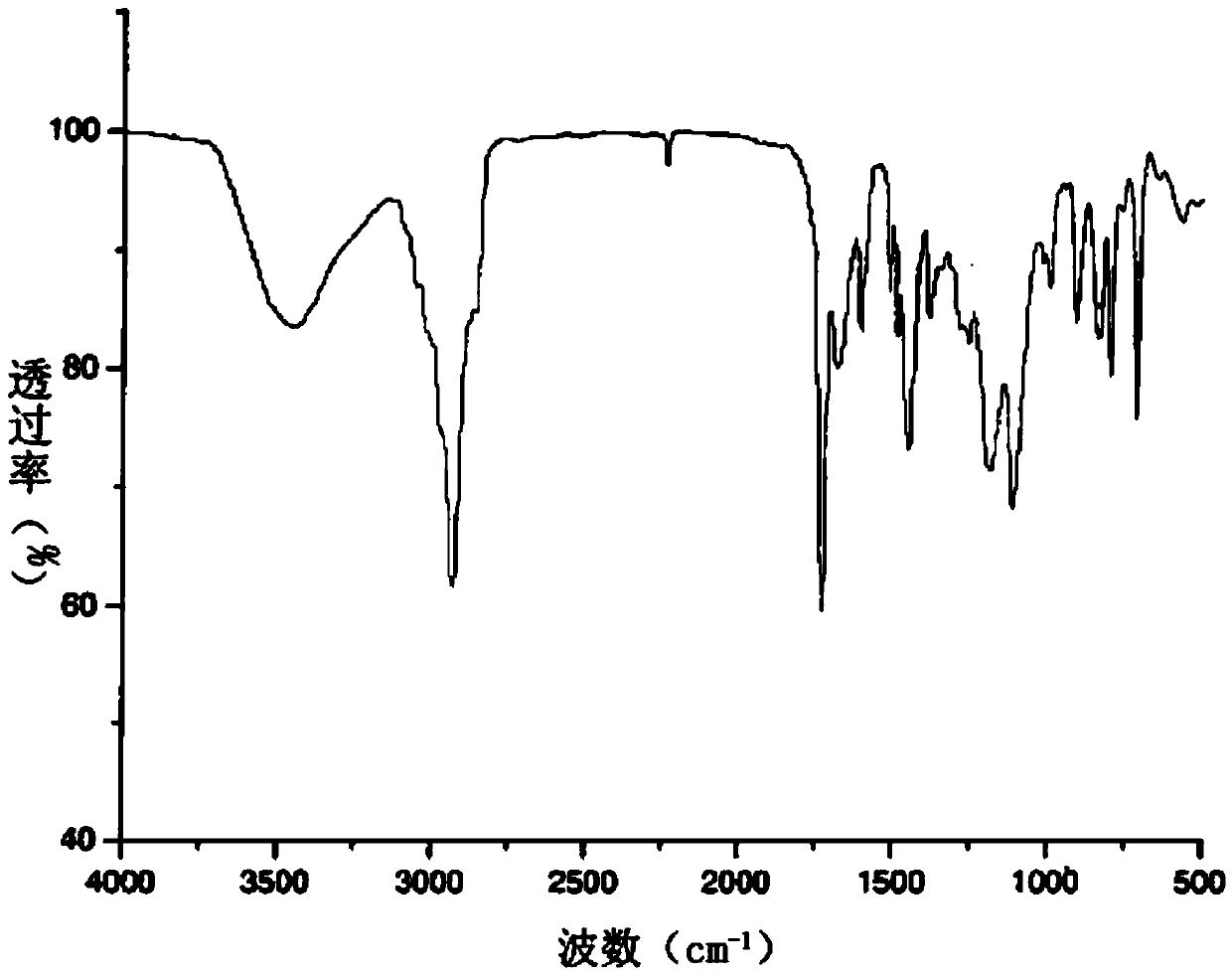

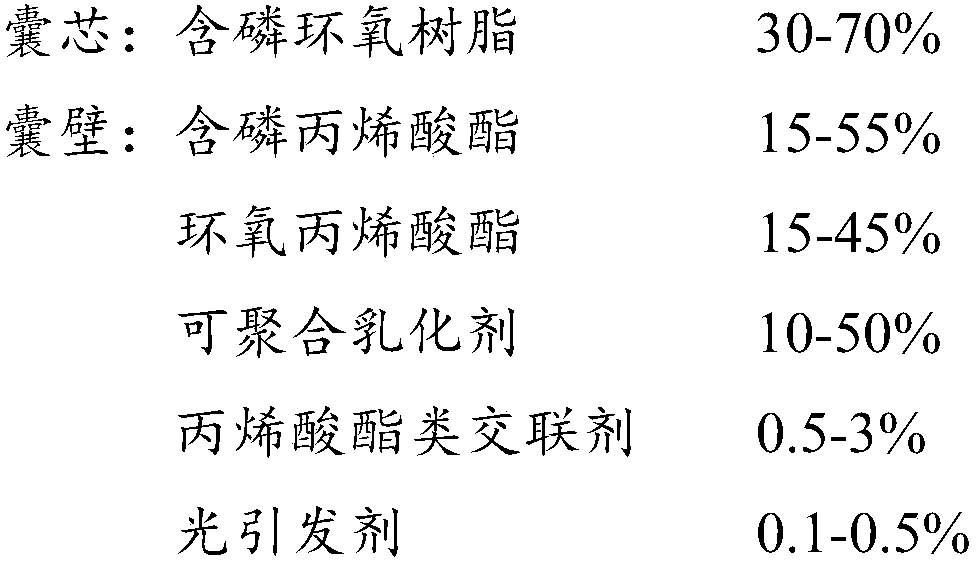

A kind of reactive flame retardant epoxy resin microcapsule and preparation method thereof

A reactive flame retardant and epoxy resin technology, used in microcapsule preparation, microsphere preparation, etc., can solve problems such as low flame retardancy, achieve good compatibility, prolong service life, and ensure the effect of safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present invention is an embodiment of a method for preparing reactive flame-retardant epoxy resin microcapsules. The method described in this embodiment includes the following steps:

[0043] (1) Dissolve 15 g of styrene-maleic anhydride copolymer sodium salt in 500 g of deionized water, and add 20 g of the core material phosphorus-containing epoxy resin (its structure is as formula (I)) and wall material in sequence under homogeneous stirring. 10g of E-51 epoxy acrylate, 10g of phosphorous acrylate (its structure is as formula (Ⅴ)), 8g of SVS, 0.5g of trimethylolpropane trimethacrylate and 2-hydroxy-2-methyl-phenyl A mixture of 0.2g of acetone, emulsified for 10min, to obtain an oil-in-water emulsion;

[0044] (2) The oil-in-water emulsion gained in the step (1) is irradiated with ultraviolet light (power 1500w, lamp distance 10cm) for 10min immediately, so that the surface of the oil-in-water is solidified to form a film;

[0045] (3) Transfer the suspension cure...

Embodiment 2

[0047] The present invention is an embodiment of a method for preparing reactive flame-retardant epoxy resin microcapsules. The method described in this embodiment includes the following steps:

[0048] (1) Dissolve 20g of gelatin in 500g of deionized water, add 25g of core material phosphorus-containing epoxy resin (its structure is as formula (II)) and 12g of wall material E-711 epoxy acrylate, A mixture of 10 g of phosphorus-containing acrylate (its structure is as in formula (Ⅴ)), 10 g of HPMAS, 0.5 g of pentaerythritol triacrylate and 0.2 g of 1-hydroxycyclohexyl phenyl ketone was emulsified for 10 minutes to obtain an oil-in-water emulsion;

[0049] (2) The oil-in-water emulsion gained in the step (1) is irradiated with ultraviolet light (power 1500w, lamp distance 10cm) for 10min immediately, so that the surface of the oil-in-water is solidified to form a film;

[0050] (3) Transfer the suspension cured by ultraviolet light into 1000ml water for sedimentation, pour out ...

Embodiment 3

[0052] The present invention is an embodiment of a method for preparing reactive flame-retardant epoxy resin microcapsules. The method described in this embodiment includes the following steps:

[0053] (1) Dissolve 15g of sodium dodecylbenzenesulfonate in 500g of deionized water, and add 30g of core material phosphorus-containing epoxy resin (its structure is as formula (Ⅲ)) and wall material E- 51 15g of epoxy acrylate, 10g of phosphorous acrylate (its structure is as (Ⅴ)), 10g of AMPS-Na, 0.5g of tetraethylene glycol dimethacrylate and 0.2g of 2-hydroxy-2-methyl-phenylacetone g of the mixture, emulsified for 10min to obtain an oil-in-water emulsion;

[0054] (2) The oil-in-water emulsion gained in the step (1) is irradiated with ultraviolet light (power 1500w, lamp distance 10cm) for 10min immediately, so that the surface of the oil-in-water is solidified to form a film;

[0055] (3) Transfer the suspension cured by ultraviolet light into 1000ml water for sedimentation, po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com