Thermolator and manufacture method of valve body of thermolator

A production method and thermostat technology, applied in the field of heat exchange, can solve problems such as lubricant passage blockage, increased cost, leakage, etc., and achieve the effects of enhancing sealing, reducing size, and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

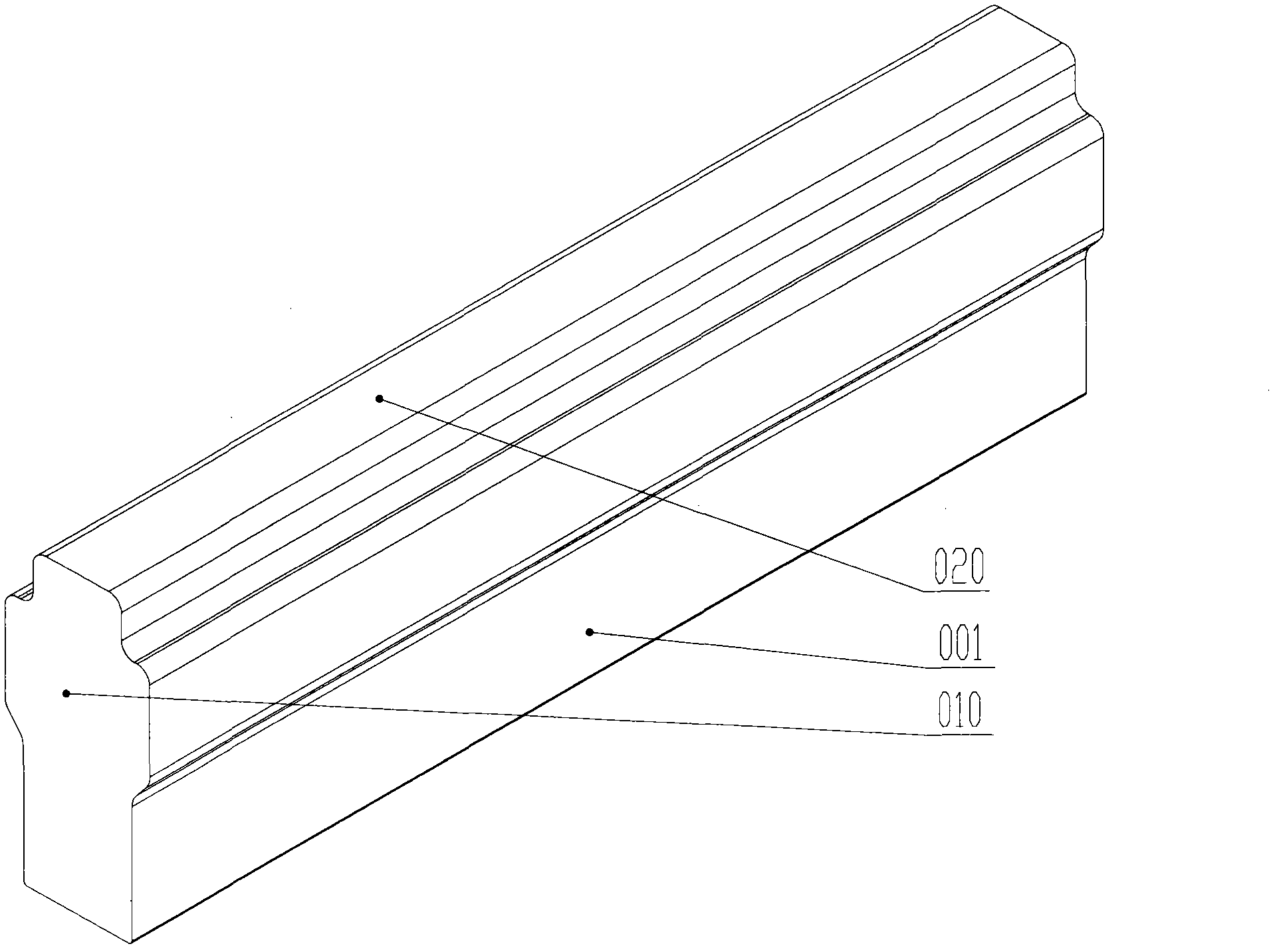

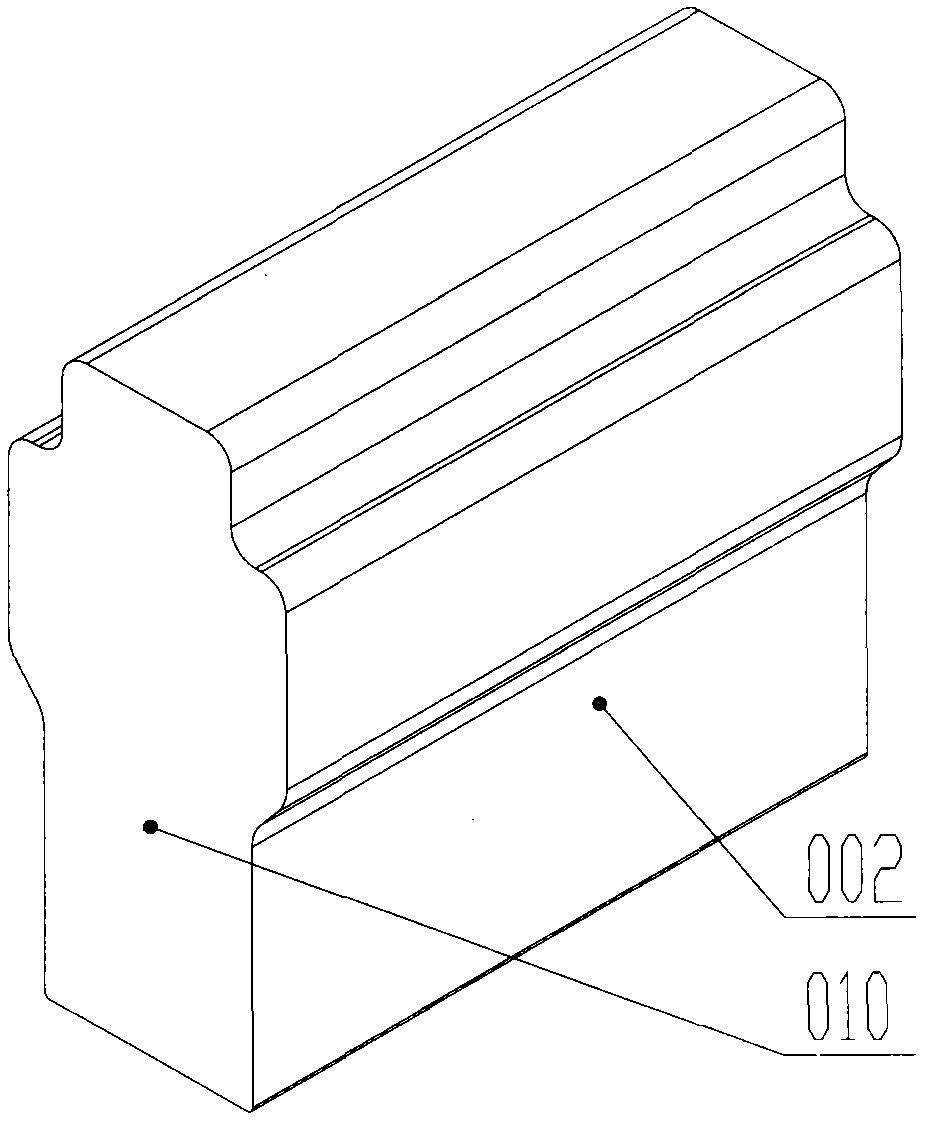

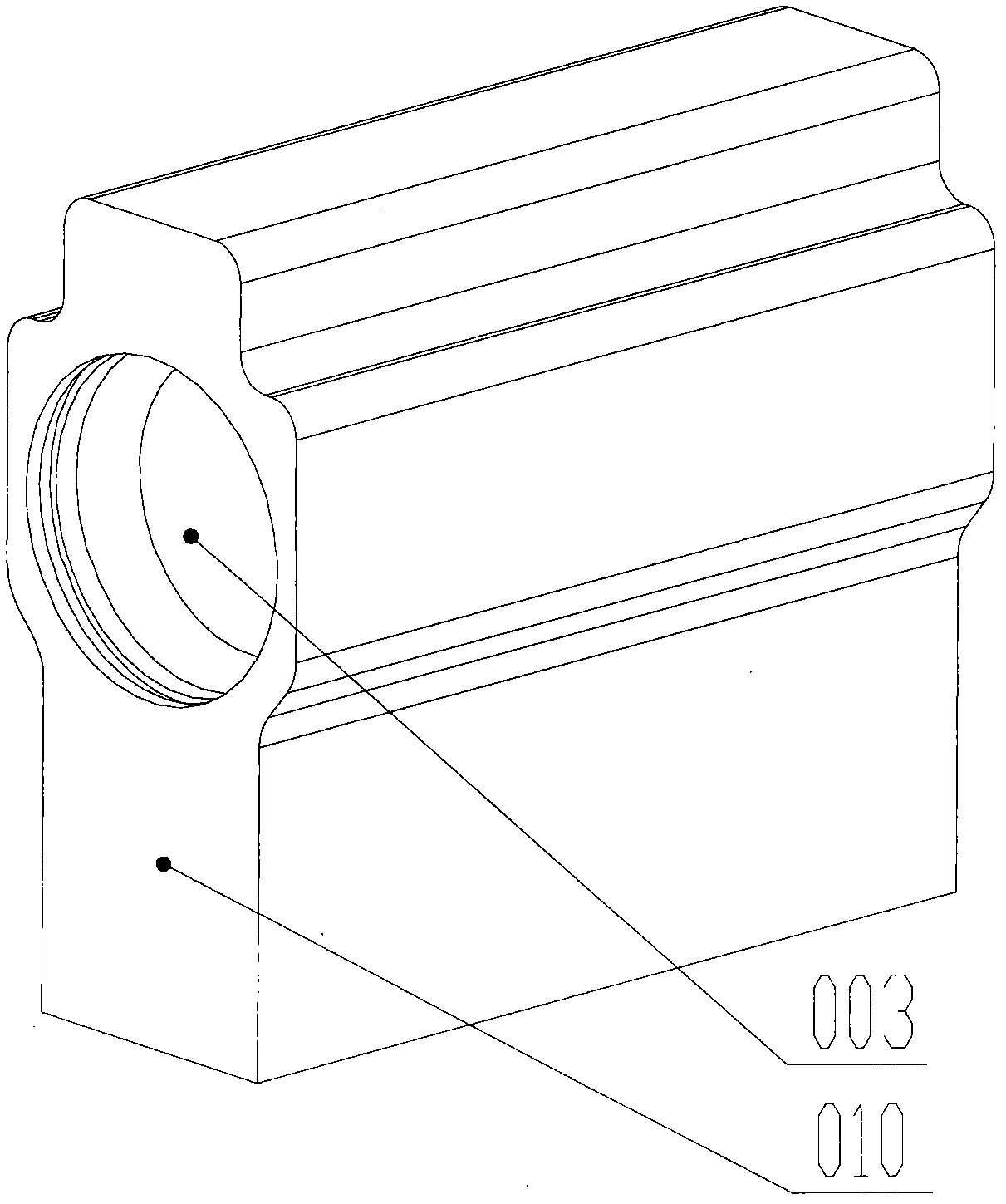

[0076] Such as Figure 8a to Figure 9 The thermostat shown includes a valve body 102 provided with a central hole 105 and a thermodynamic element fitted in the central hole 105 .

[0077] The valve body 102 also includes two through holes respectively communicating with the central hole 105 : a first flow channel 104 and a second flow channel 107 . Wherein, the first end of the second flow channel 107 and the first flow channel 104 communicate with the inlet and outlet of the external fluid cooling device respectively; And the second quick connector 301. It can be seen from the figure that the first quick connector 300 and the second quick connector 301 are integrated with the valve body 102 .

[0078] The inner diameter of the central hole 105 is greater than the inner diameter of the second flow channel 107 and communicates with it. One end of the central hole 105 close to the second flow channel 107 is partially overlapped with the second flow channel 107. The outer perip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com