Low carbon and energy-saving gas heat treatment tunnel kiln

A tunnel furnace and gas technology, which is applied in the field of heat treatment, can solve the problems of low combustion temperature and low fuel combustion rate, and achieve the effect of saving gas supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

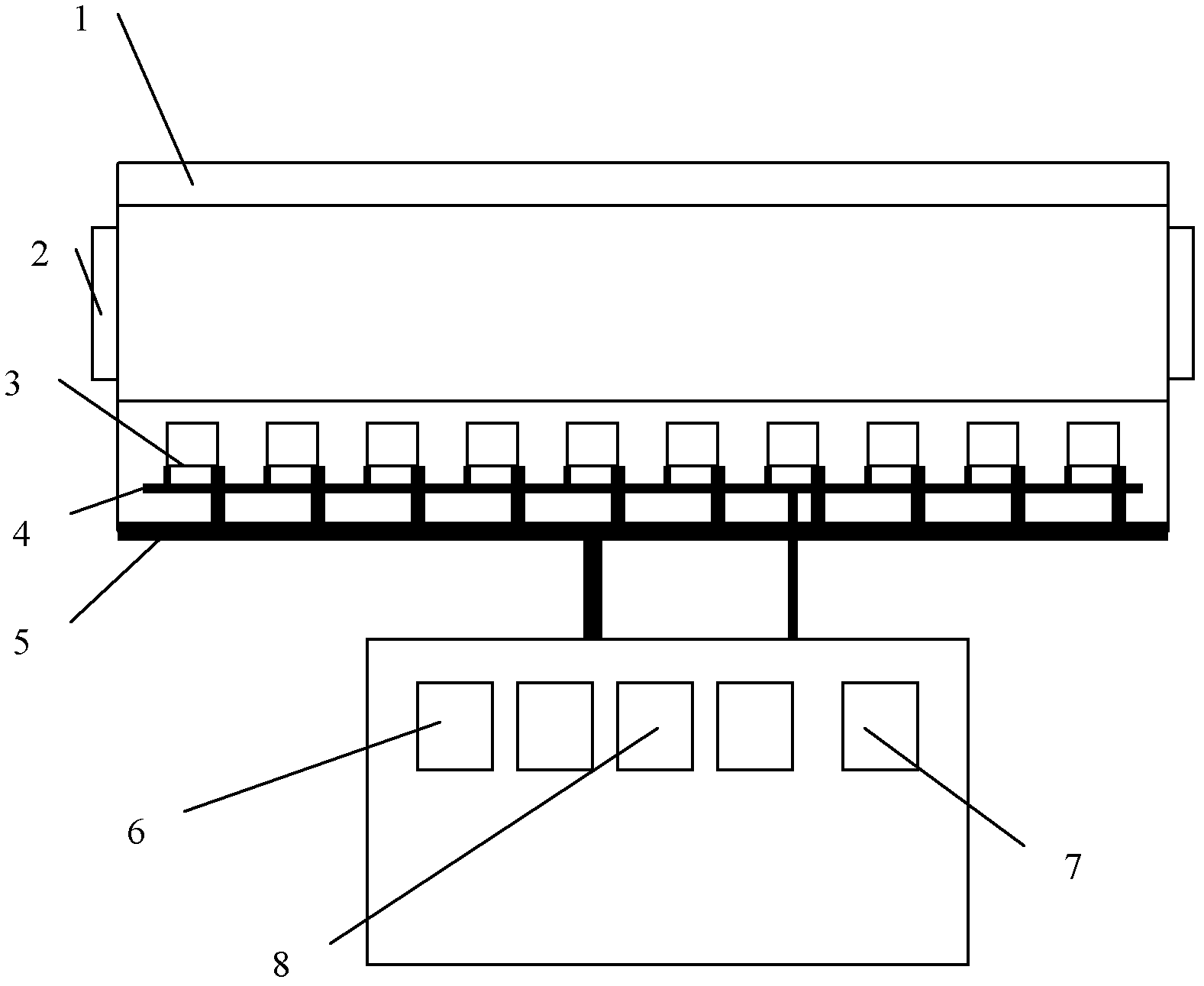

[0014] Such as figure 1 As shown, the low-carbon energy-saving gas heat treatment tunnel furnace of the present invention mainly includes: tunnel furnace body 1, furnace door 2, burner 3, gas pipeline 4, air supply pipeline 5, oxygen-enriched generator 6, gas supply device 7 and Fan 8, etc., a plurality of burners 3 are arranged under the tunnel furnace body 1, the burners 3 are connected to the gas supply device 7 through the gas pipeline 4, and the burners 3 are connected to the oxygen-enriched generator 6 and the fan 8 through the air supply pipeline 5, Furnace doors 2 are arranged on both sides of the tunnel furnace body 1 . In this embodiment, 10 burners are evenly distributed, and the interval between adjacent burners is 1.5 meters.

[0015] In the present invention, the burner may be a swirl burner (patent number 200920351711.8) or a cyclone gas burner (patent number 200920013848.2).

[0016] Principle of operation of the present invention:

[0017] First ignite the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com