Automatic calibration method of air compressor system sensor

An automatic calibration and air compressor technology, applied in thermometer testing/calibration, instruments, scientific instruments, etc., can solve problems affecting the normal operation of the air compressor system, large errors in temperature and pressure parameters, and many operating links, etc., to achieve Improve work efficiency and calibration accuracy, avoid human error, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

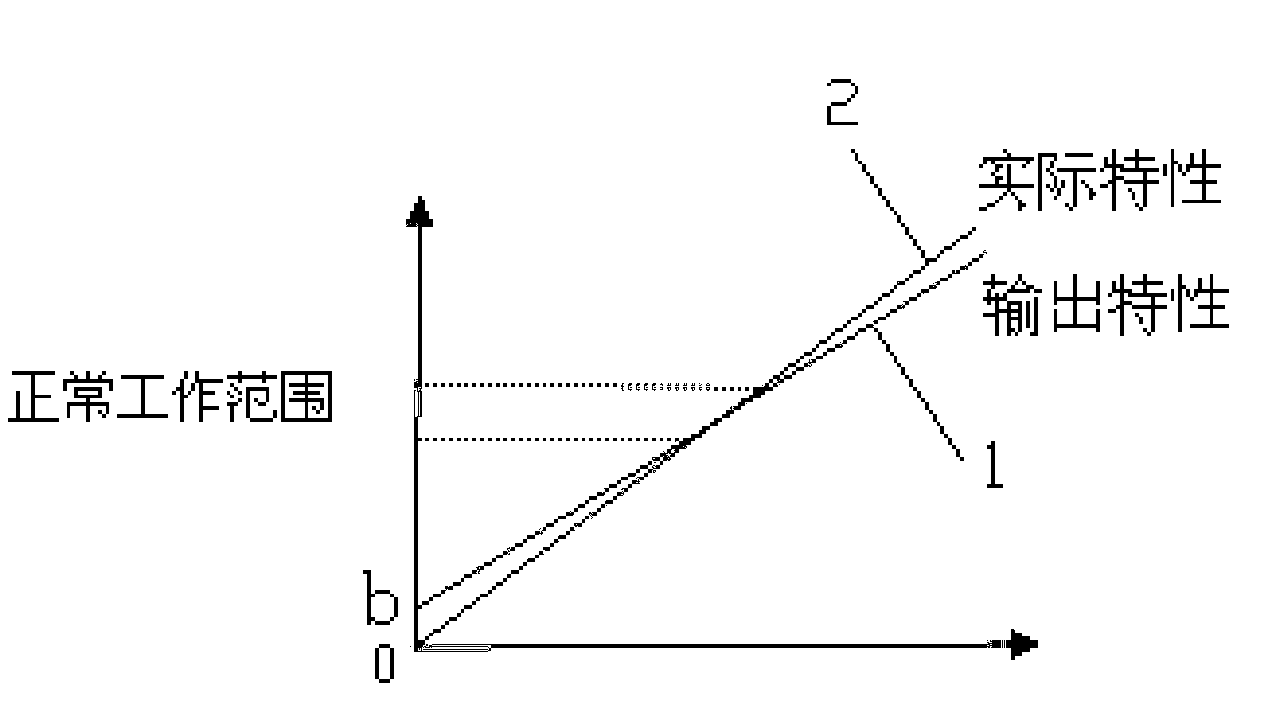

[0031] The automatic calibration method of the air compressor system sensor of the present invention, the air compressor system in a specific working environment, the normal working temperature and pressure have a fixed range, according to the characteristics of the data acquisition module and the analog / digital conversion module of the air compressor system , the sensor output signal is converted into a voltage signal by the data acquisition module, and the voltage signal is converted into a digital signal by the analog / digital conversion module, and the output value of the sensor through the data acquisition module and the analog / digital conversion module is:

[0032] (1)

[0033] In the formula: K max — sensor nominal measurement upper limit,

[0034] K min — sensor nominal measurement lower limit,

[0035] u max — the upper limit of the collected voltage signal,

[0036] u min — the lower limit of the collected voltage signal,

[0037] u REF — the reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com