Fatigue testing machine used for small module wheel gear symmetry fatigue test

A technology of fatigue testing machine and small modulus gear, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of wasting experimental information, high experimental cost, and low experimental efficiency, and achieve the effect of reducing experimental cost and improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

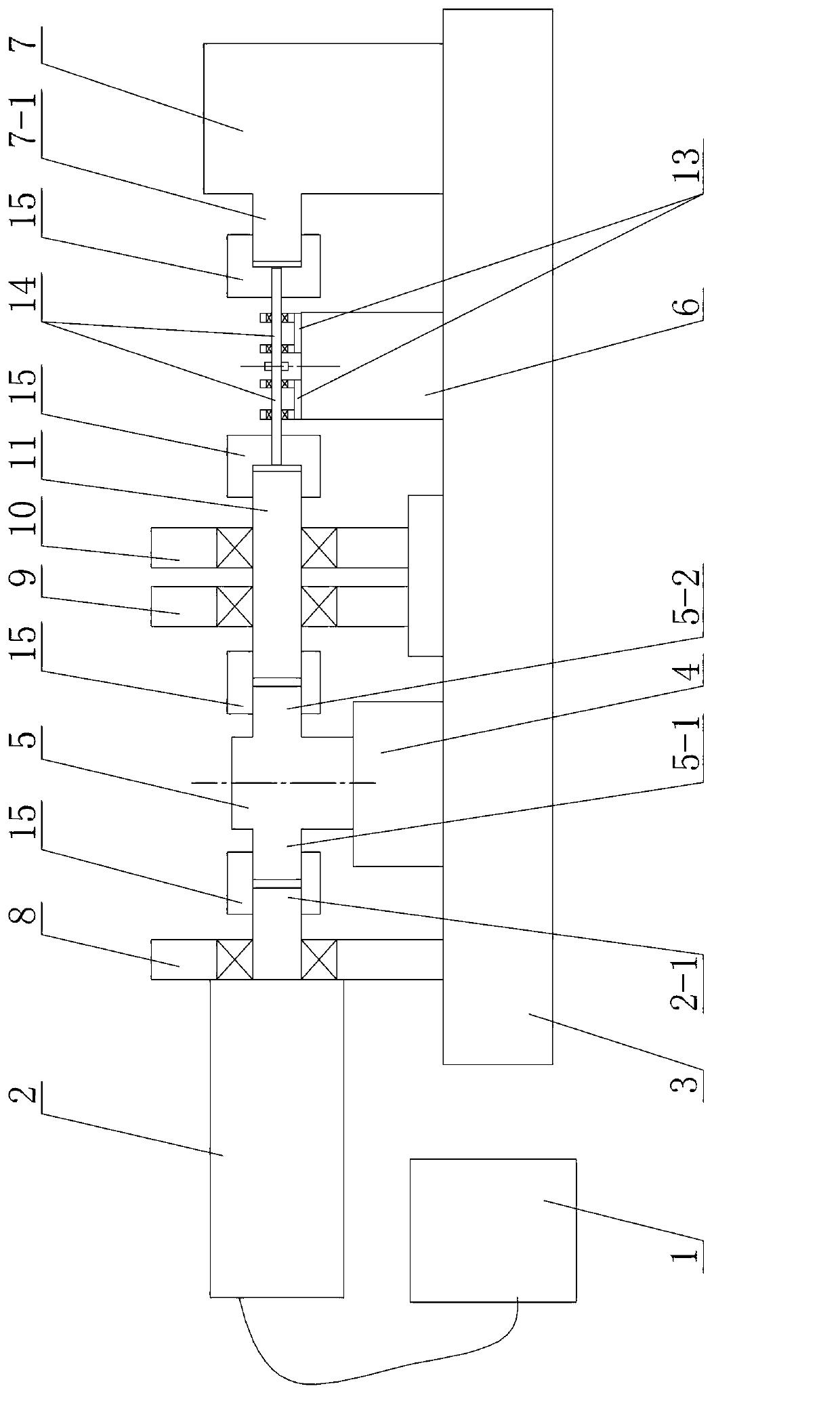

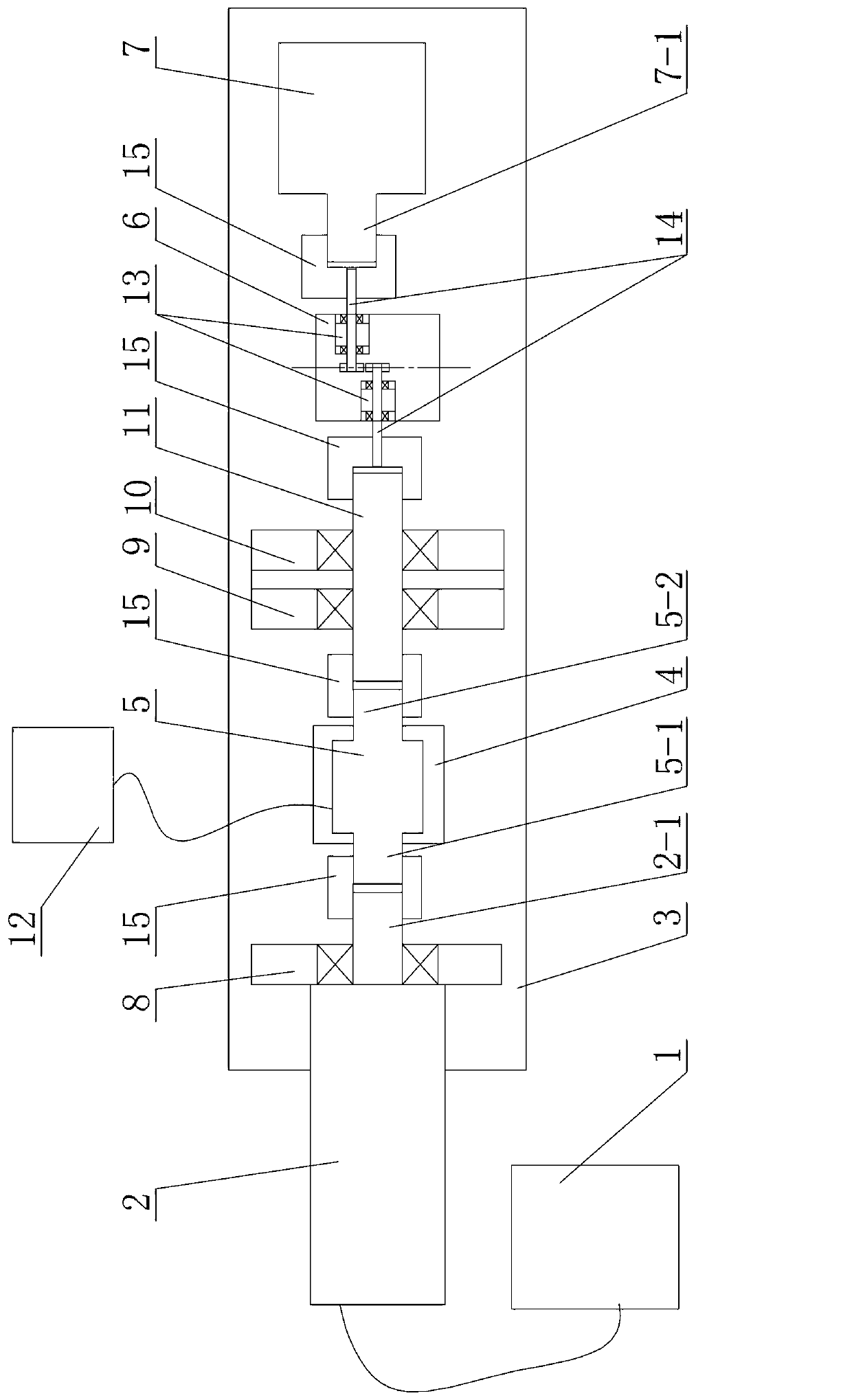

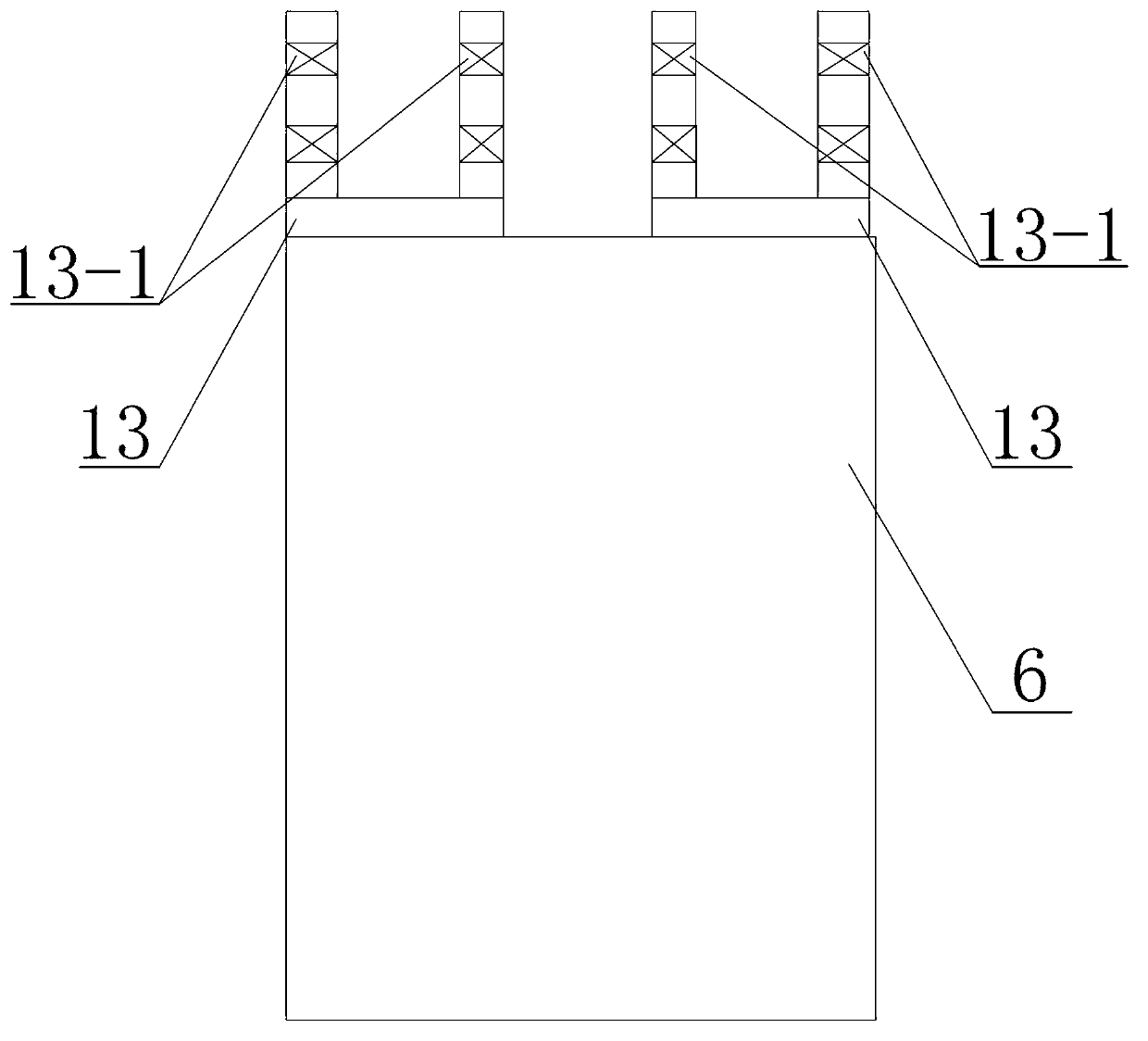

[0009] Specific implementation mode one: combine Figure 1 to Figure 7 To illustrate, a fatigue testing machine for symmetrical fatigue testing of small modulus gears in this embodiment includes a controller 1, a servo motor 2, a supporting base 3, a supporting base 4, a torque sensor 5, a micro-motion platform 6, and a magnetic powder brake 7 , the first bearing support 8, the second bearing support 9, the third bearing support 10, the connecting shaft 11, the computer 12, two mounting supports 13, two gear assembly shafts 14 and a plurality of couplings 15, The upper surface of the support base plate 3 is sequentially fixed with the first bearing support 8, the support base 4, the second bearing support 9, the third bearing support 10, the micro-motion platform 6 and the magnetic powder brake 7 along the length direction of the support base plate 3. , a torque sensor 5 is installed on the support base 4, and a mounting support 13 is respectively installed on the two ends of ...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 and figure 2 Note that the plurality of couplings 15 in this embodiment are all rigid couplings. Other components and connections are the same as those in the first embodiment.

[0011] Working principle: Firstly, the components of the fatigue testing machine are installed, the controller 1 controls the rotation of the servo motor 2, and the servo motor 2 transmits the torque to the torque sensor 5 and the connecting shaft 11 in turn, and finally transmits the torque to the two meshing shafts Adjust the micro-movement platform 6 to make each component run smoothly, then start the magnetic powder brake 7 to apply a constant torque to the two small modulus gears 16, and the torque sensor 5 synchronously collects the meshing transmission of the two small modulus gears 16 The experimental data in the process is finally input into the computer 12 to analyze the fatigue characteristics of the two small modulus gears 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com