mass balance unit

A technology of mass balancing and balancing shaft, applied in engine components, mechanical equipment, rotating parts that resist centrifugal force, etc., can solve the problems of large weight, high cost, unbalanced balancing shaft, etc., and achieve the effect of unaffected stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

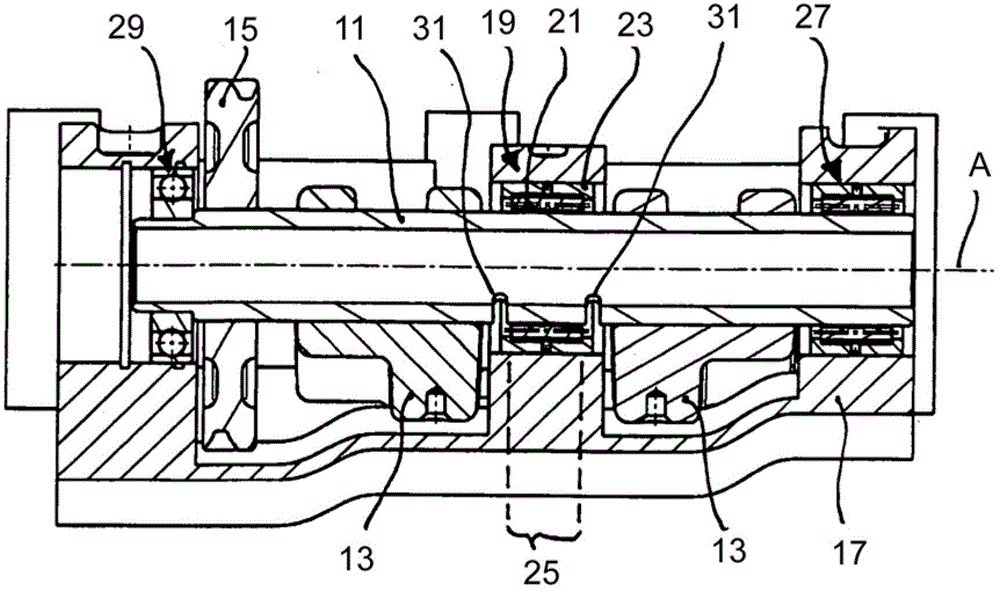

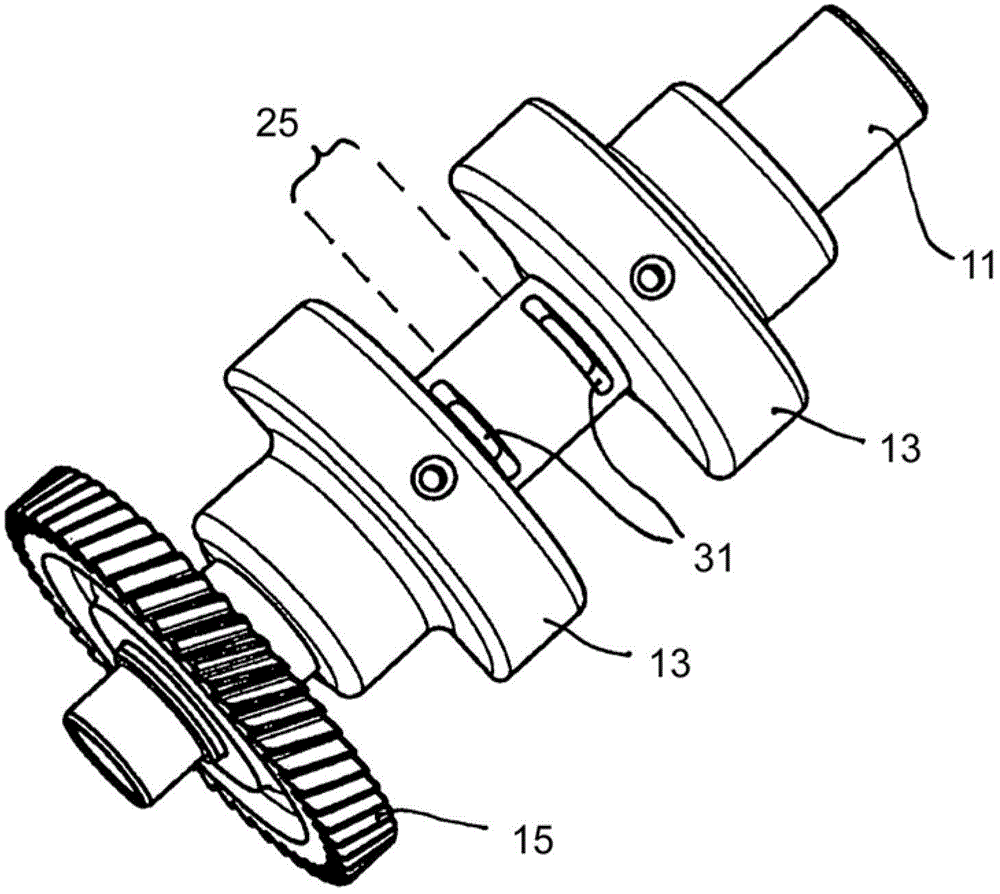

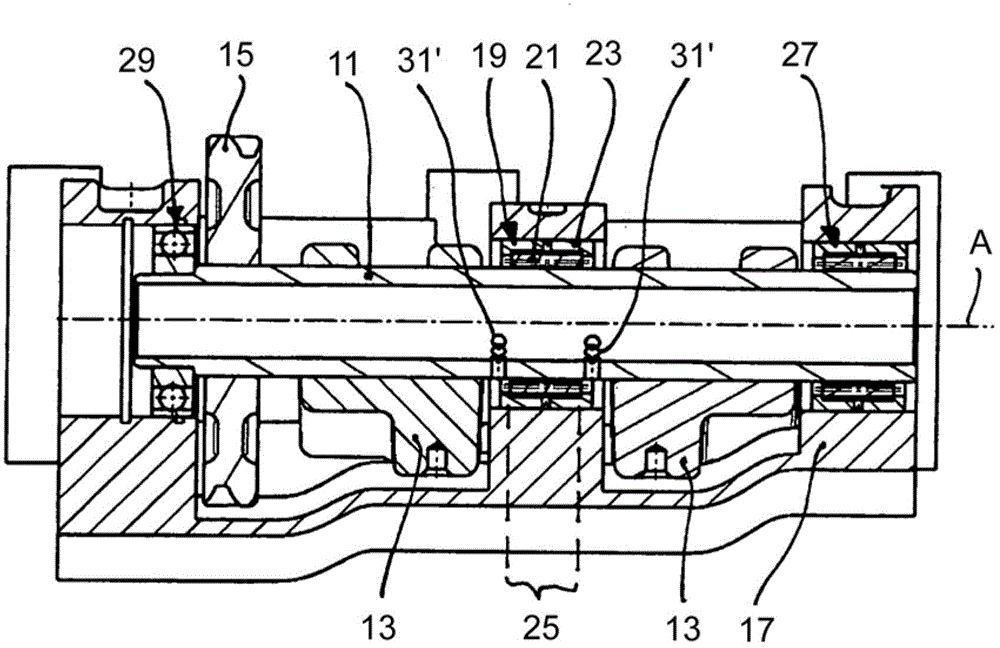

[0031] exist Figure 1a and Figure 1b The mass balance unit shown in includes a hollow, ie tubular, balance shaft 11 . Two balance weights 13 are fixed on the balance shaft 11 by, for example, thermocompression connection, screw connection, welding or positioning pins. In order to create an unbalance, the balance weights 13 are substantially in the form of semi-cylindrical parts with two fixing clips molded on them, wherein, with respect to the axis of rotation A of the balance shaft 11, the angular orientation of one balance weight 13 corresponds to The angular orientation of the other counterweight 13 corresponds. In addition, a drive wheel 15 is also fixed to the balance shaft 11 by, for example, thermocompression bonding. The drive wheel 15 can be directly drivingly connected to the crankshaft of the associated internal combustion engine to form a transmission stage. Alternatively, the drive wheel 15 can be drivingly connected to a corresponding drive wheel of a balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com