Greenhouse lift type steel frame

A lift-type, steel frame technology, applied in greenhouse cultivation, horticulture, climate change adaptation, etc., can solve problems such as unfavorable crop growth and development, insufficient light, poor temperature adjustment effect, etc., achieve novel design, increase light area, reduce greenhouse height effect

Inactive Publication Date: 2013-06-12

郝伟

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, most of the greenhouses used in agricultural production are solar energy-saving greenhouses and multi-span greenhouses built in the last century. These greenhouses have disadvantages such as poor temperature regulation effect, insufficient light, and disadvantages for crop growth and development in winter.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

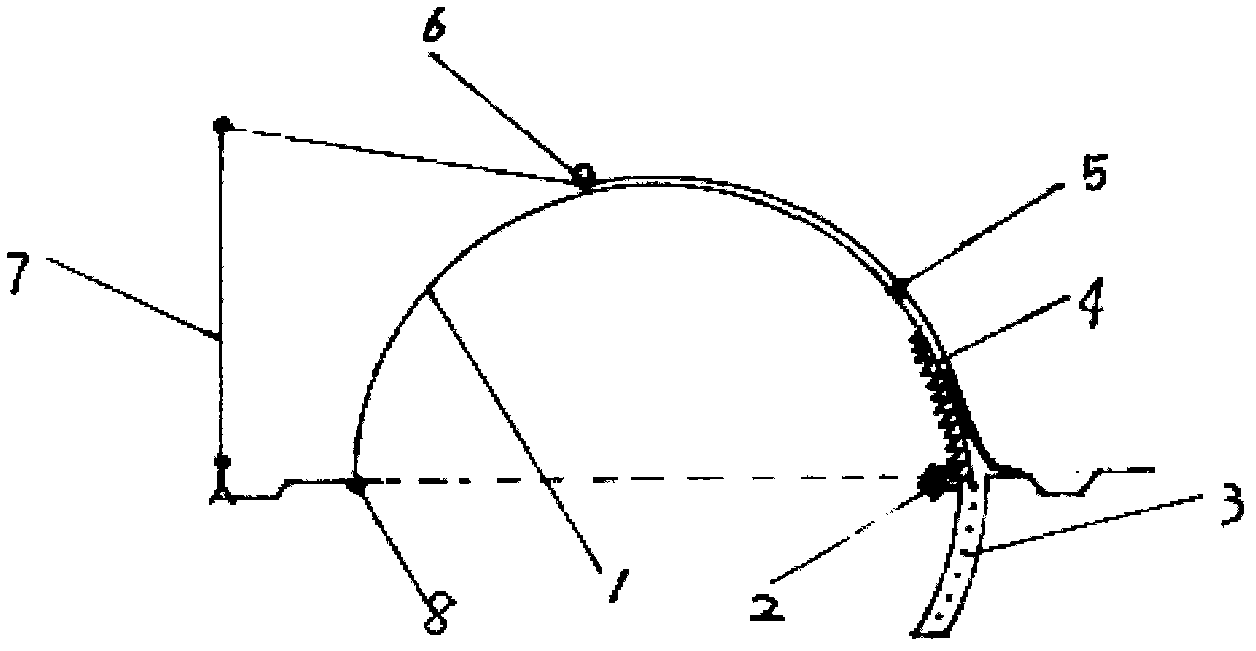

[0008] Specific examples are given by the legends. The legend shows the structural diagram of the greenhouse lifting steel frame, which includes a semi-circular steel frame 1, a lifting gear 2, a drop frame groove 3, a lifting tooth 4, a temperature-regulating fixed plate 5, a temperature-regulating quilt 6, and a temperature-regulating Rotated system 7, steel frame front rotating shaft 8.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A greenhouse lift type steel frame belongs to facility agricultural greenhouse structural devices. The frame comprises a plurality of semi-circle-arc steel frames, a lifting gear, a frame loading groove, lifting teeth, a thermoregulation quilt fixing plate and a front steel plate rotating shaft. The frame is ingenious in design, unique in structure and quick to assemble and has strong resistance and a wide application scope; a lighting area can be increased by above 30%, the height of a greenhouse can also be lowered, and the anti-wind capability is increased; the frame is particularly suitable for being applied to planting and breeding industries; and the frame is low in manufacturing cost and has practicability and popularization performance.

Description

technical field [0001] The invention relates to a lift-type steel frame for greenhouses, which belongs to structural devices for greenhouses in facility agriculture. Background technique [0002] At present, most of the greenhouses used in agricultural production are solar energy-saving greenhouses and multi-span greenhouses built in the last century. These greenhouses have the disadvantages of poor temperature regulation, insufficient light, and unfavorable growth and development of crops in winter. Contents of the invention [0003] The invention provides a greenhouse lifting type steel frame, which can overcome the above disadvantages. [0004] The present invention is realized by adopting the following technical proposals: a greenhouse elevating steel frame, which includes a mostly semi-circular steel frame, an elevating gear, a drop frame groove, an elevating tooth, a temperature-regulating fixed plate, a front rotating shaft of the steel frame, and The features are:...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A01G9/14

CPCY02A40/25

Inventor 郝伟

Owner 郝伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com