Green environmental control device and method for plastic cold shed

A cold shed and plastic technology, applied in botany equipment and methods, comprehensive factory control, electrical program control, etc., can solve problems such as increased equipment cost, difficult installation and maintenance, and reduced yield and quality, and reduce the restrictions on placement conditions and environmental protection. Optimizing regulation and improving the effect of energy scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

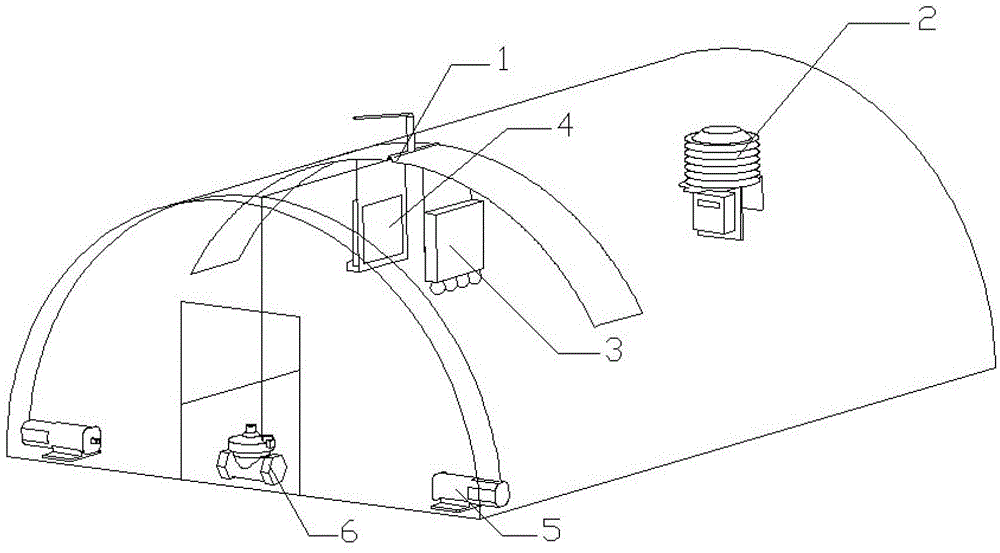

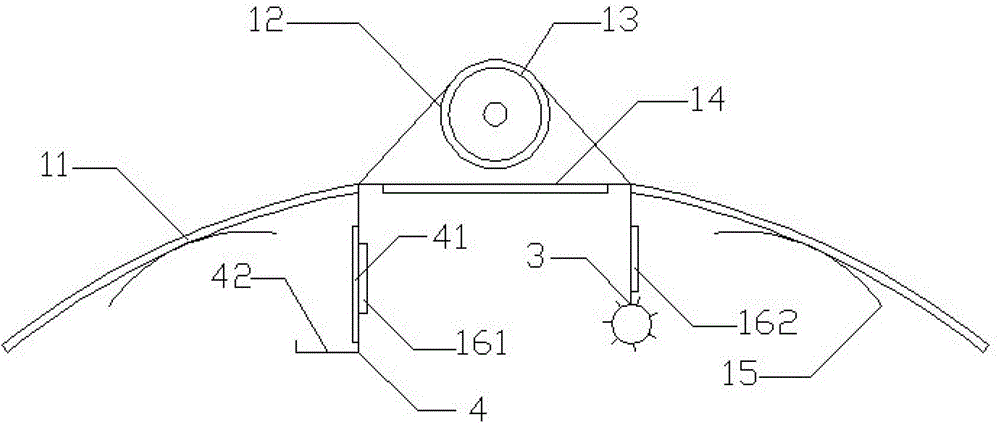

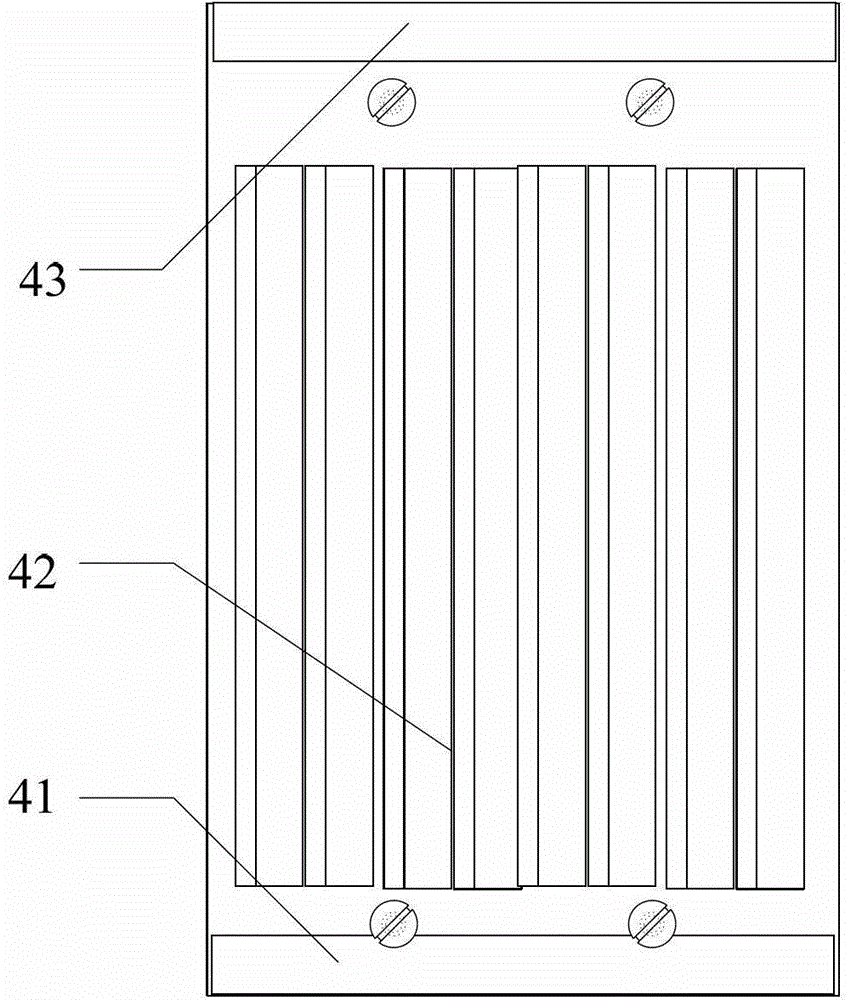

[0046] Such as figure 1 with 2 As shown, the green environmental control device for plastic cold sheds of the present invention includes a solar environment control terminal 1, an execution device, a wireless charging device, and a sensor 2. The solar environment control terminal 1 includes a solar panel 11, a rotating shaft 12 and a circuit board 14, and the solar panel 11 is installed on both sides of the top of the plastic cold shed; the rotating shaft 12 is arranged on the top of the plastic cold shed, and the first lithium battery 13 is provided inside the rotating shaft 12; The chip charges the first lithium battery 13, preferably the SPV1040 chip or SPV1020 chip i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com