Process for surface treatment and surface modification of edge sealing strip by using deuterium lamp UV (Ultraviolet) radiation light

A surface treatment and surface modification technology, applied in the field of mechanical processing technology, can solve the problems of weak response range and strength, and achieve the effect of simple implementation device, reduction of placement restrictions, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

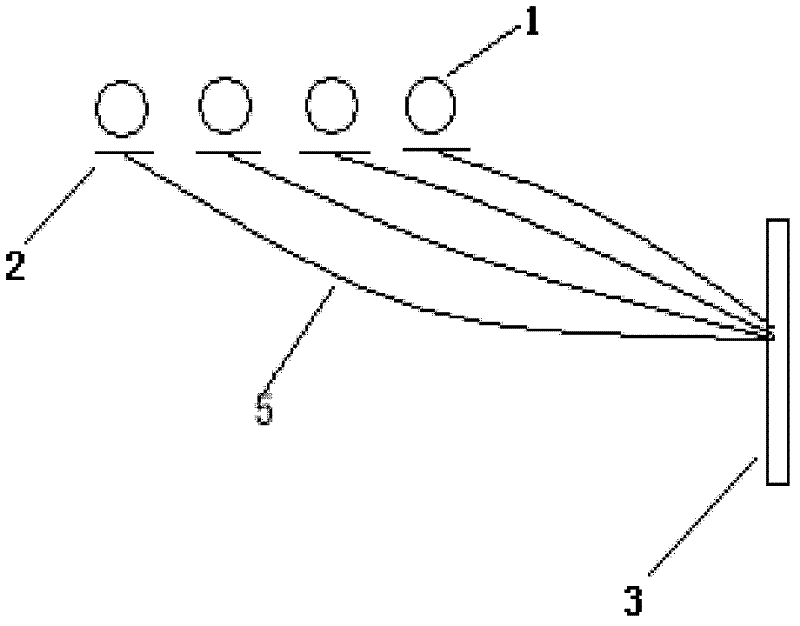

[0024] The embodiments of using multiple deuterium lamps to directly irradiate the edge strip and irradiating the edge strip through optical fibers will be described respectively below in conjunction with the accompanying drawings.

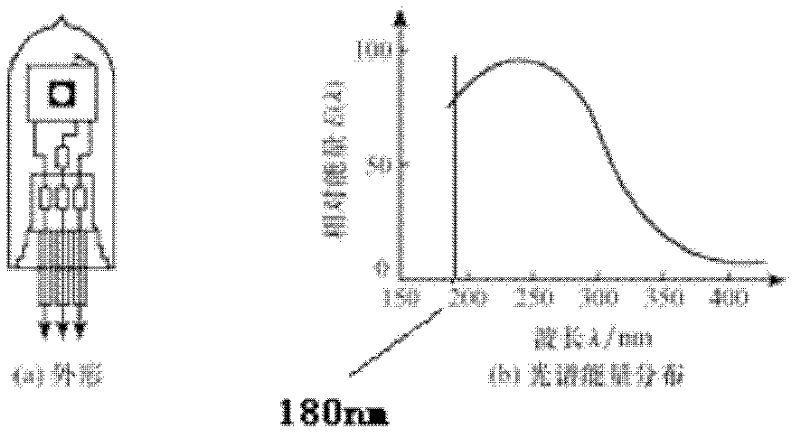

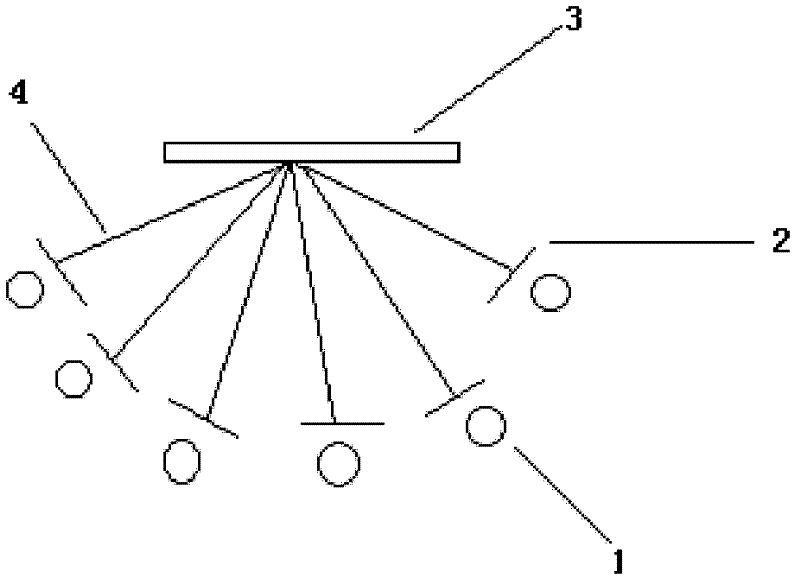

[0025] figure 1 It is a schematic diagram of a process in which a plurality of deuterium lamps directly irradiate the edge band to carry out surface treatment. In this embodiment, six deuterium lamps are used (the number of deuterium lamps is determined according to the power of the deuterium lamp and the material of the edge band), and the deuterium lamp adopts The gas discharge light source used in the ultraviolet spectrophotometer, the edge banding adopts ordinary low-energy surface materials such as polyvinyl chloride, and the total energy intensity of the deuterium lamp acting on the edge banding should exceed 6.6eV. Six deuterium lamps 1 are located on one side of the edge banding strip, arranged evenly, and are at the same distance from a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com