A kind of manufacturing method of nose bridge prosthesis for plastic surgery

A manufacturing method and technology for the bridge of the nose, applied in the direction of prosthesis, medical science, etc., can solve the problems of easy displacement and wear, increase flexibility, increase surface friction, and reduce the probability of displacement and wear in the body Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

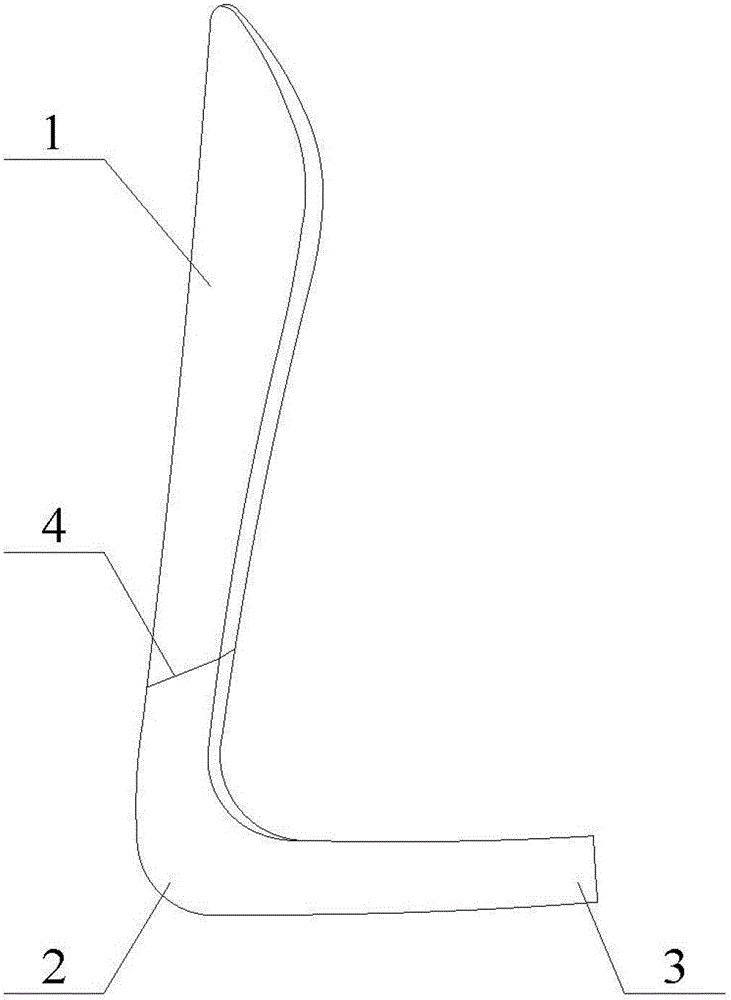

Image

Examples

Embodiment 1

[0035] Embodiment 1: The manufacturing method steps of bridge of the nose prosthesis of the present invention are as follows:

[0036] a. Compression of the base material of the back of the nose and the base material of the tip of the nose

[0037] (1) Compression of base material on the back of the nose

[0038] Mixed silicone rubber: add 0.4% white by weight to the implantable silicone rubber compound (mixed rubber is the rubber compounded by mixing raw rubber or plasticized rubber according to the formula and the compounding agent through the rubber mixer). The coloring agent is mixed evenly on the rubber mixer, and the mixing time is 15 minutes.

[0039] Compress base material: Divide the mixed rubber according to the weight of the molding material list in Table 1, and perform hot-press molding in four types of molds. Press the mold and check whether it is matched. Adjust the temperature of the flat vulcanizer to be 116° C., and the pressing time to be 8 minutes. After...

Embodiment 2

[0053]a. Compression of the base material of the back of the nose and the base material of the tip of the nose

[0054] (1) Compression of base material on the back of the nose

[0055] Mixing silicone rubber: add 0.3% white coloring agent to the implant grade silicone rubber compound, mix evenly on the rubber mixer, and the mixing time is 15 minutes.

[0056] Press the base material: put the mixed rubber strip in the mold to close the mold, press the mold down with your hands, and check whether it is matched. Adjust the temperature of the flat vulcanizer to be 106° C., and the pressing time to be 8 minutes. After the specified time is reached, the mold is taken out immediately, and trimmed with scissors with a curved arc to obtain the base material of the back of the nose.

[0057] (2) Compression of the base material of the nose tip

[0058] The base material 2 of the tip of the nose is mixed and pressed evenly by adding 0.05% white coloring agent to the implantable liqui...

Embodiment 3

[0068] a. Compression of the base material of the back of the nose and the base material of the tip of the nose

[0069] (1) Compression of base material on the back of the nose

[0070] Mixing silicone rubber: add 0.5% white coloring agent to the implant grade silicone rubber compound, mix evenly on the rubber mixer, and the mixing time is 15 minutes.

[0071] Press the base material: put the mixed rubber strip in the mold to close the mold, press the mold down with your hands, and check whether it is matched. Adjust the temperature of the flat vulcanizer to be 126° C., and the pressing time to be 8 minutes. After the specified time is reached, the mold is immediately taken out, and trimmed with curved scissors to obtain the nasal dorsum base material 1.

[0072] (2) Compression of the base material of the nose tip

[0073] The base material 2 of the tip of the nose is mixed and pressed evenly by adding 0.15% white coloring agent to the implantable liquid silicone rubber, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com