Vertical high-speed cement colloid mixer

A mixer and mixing motor technology, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of restricting the efficient grouting construction, insufficient power of the mixing motor, and high pressure of cement colloid, etc., to shorten the time of grouting The effect of shortening the construction period, saving equipment maintenance time, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

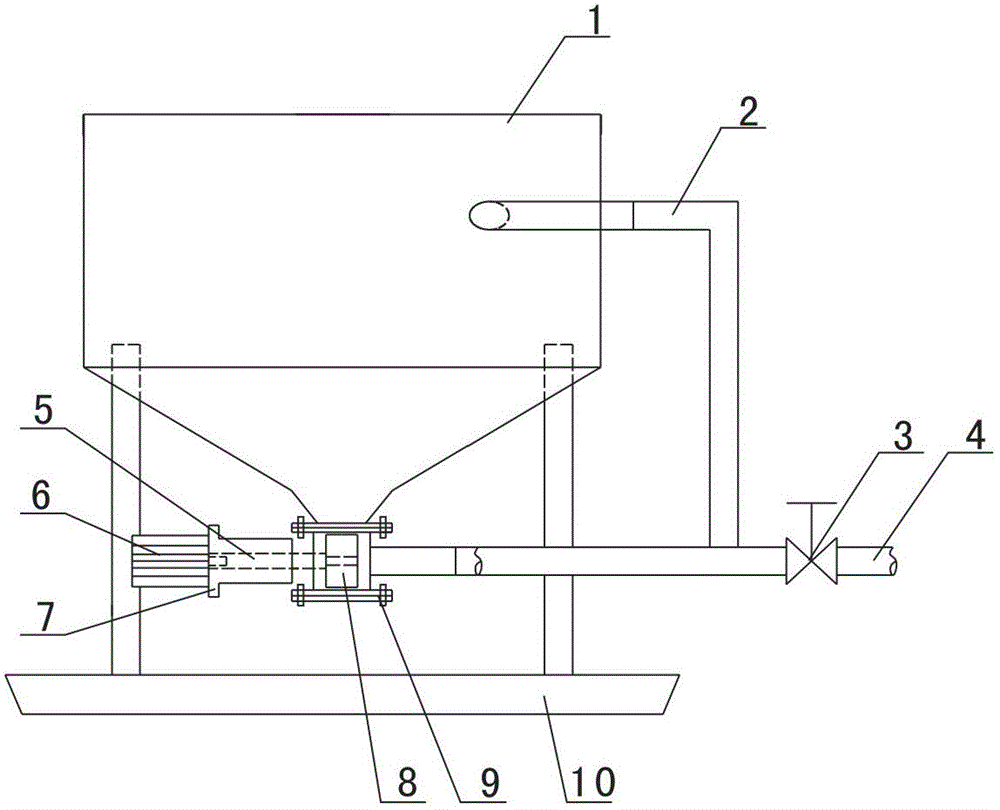

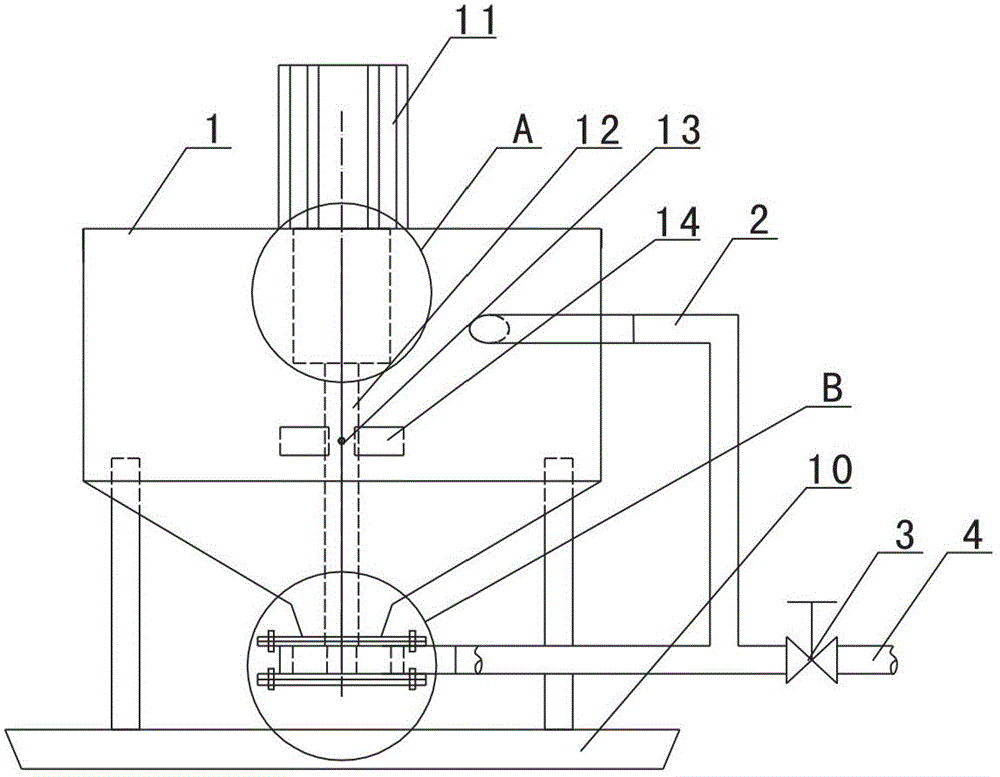

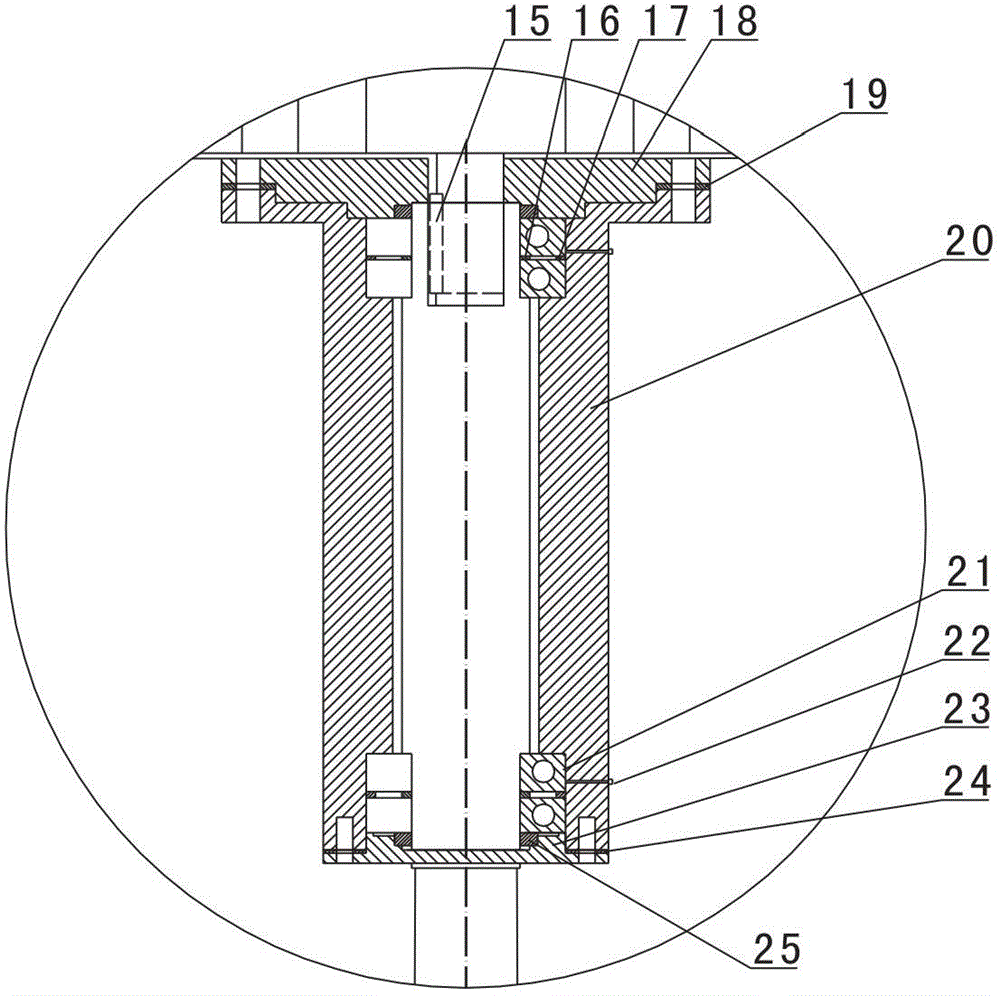

[0020] Such as figure 2 , image 3 with Figure 4 As shown, the vertical high-speed cement colloid mixer of the present invention comprises a mixing barrel 1 and a stirring motor 11, the stirring motor 11 is a vertical stirring motor, the stirring motor 11 is installed above the mixing barrel 1, and the rotating shaft of the stirring motor 11 is placed on the The upper end of the vertical shaft 12 at the center of the mixing tank 1 is connected by a shaft key 15, the middle section of the vertical shaft 12 is fixedly equipped with a first stirring impeller 14 through a positioning nut 13, and the bottom of the vertical shaft 12 is fixedly installed with a second impeller through a key 26 and a lock nut 27. Two stirring impellers 29, the bottom of the vertical shaft 12 is located at the center of the outlet of the mixing bucket 1 bottom, the outlet of the mixing buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com