a heat-absorbing material

A technology of heat-absorbing materials and bulk materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as too narrow application range, and achieve the effect of effective instantaneous heat peak and simple production and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

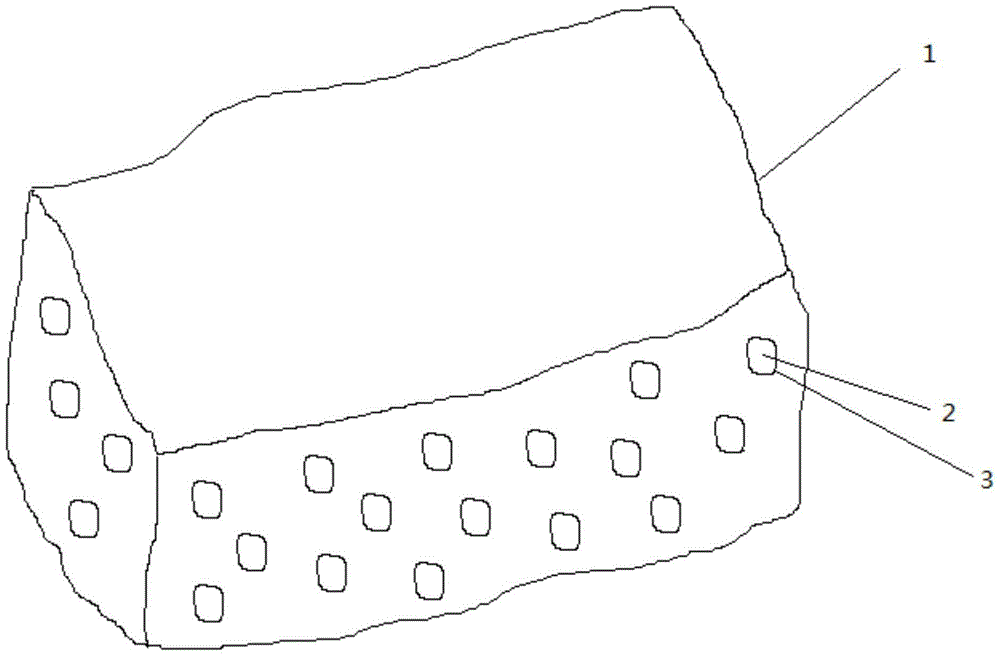

[0013] The heat absorbing material of the present invention includes a carrier and microcapsules containing at least one phase change material, and the microcapsules are evenly distributed in the carrier. The carrier can adopt foam material, solid material, liquid material, paste material and the like. The carrier material can be thermally conductive, such as thermally conductive solid shock-absorbing materials, such as rubber pads in mobile phones; or solid thermally conductive elastic materials, such as thermally conductive gap pads or colloids; or thermally conductive liquid elastomers, such as thermally conductive liquid rubber; Or thermal paste, such as thermal paste or thermal grease. In addition, the carrier mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com