Processing apparatus for preventing pistons on hydraulic cylinder for hammer from deforming, and method thereof

A processing device and processing method technology, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of increased grinding allowance, high scrap rate of piston 12, no piston from grinding, and reduce grinding. Quantity, simple processing method, and the effect of reducing waste and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

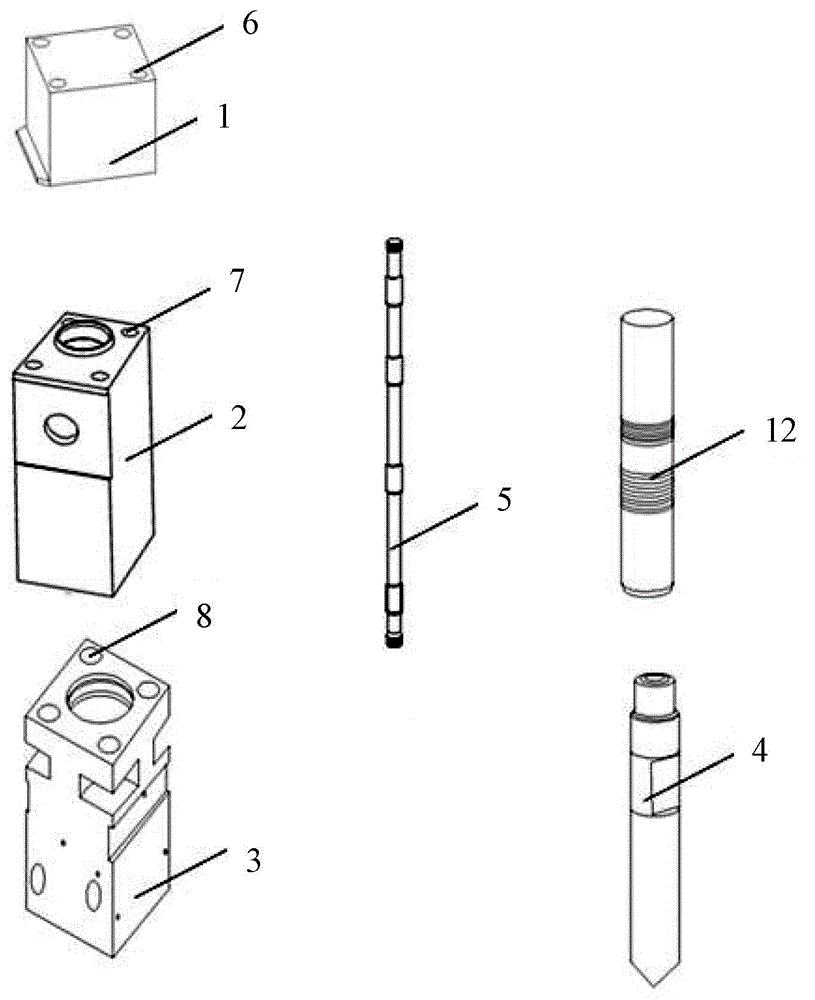

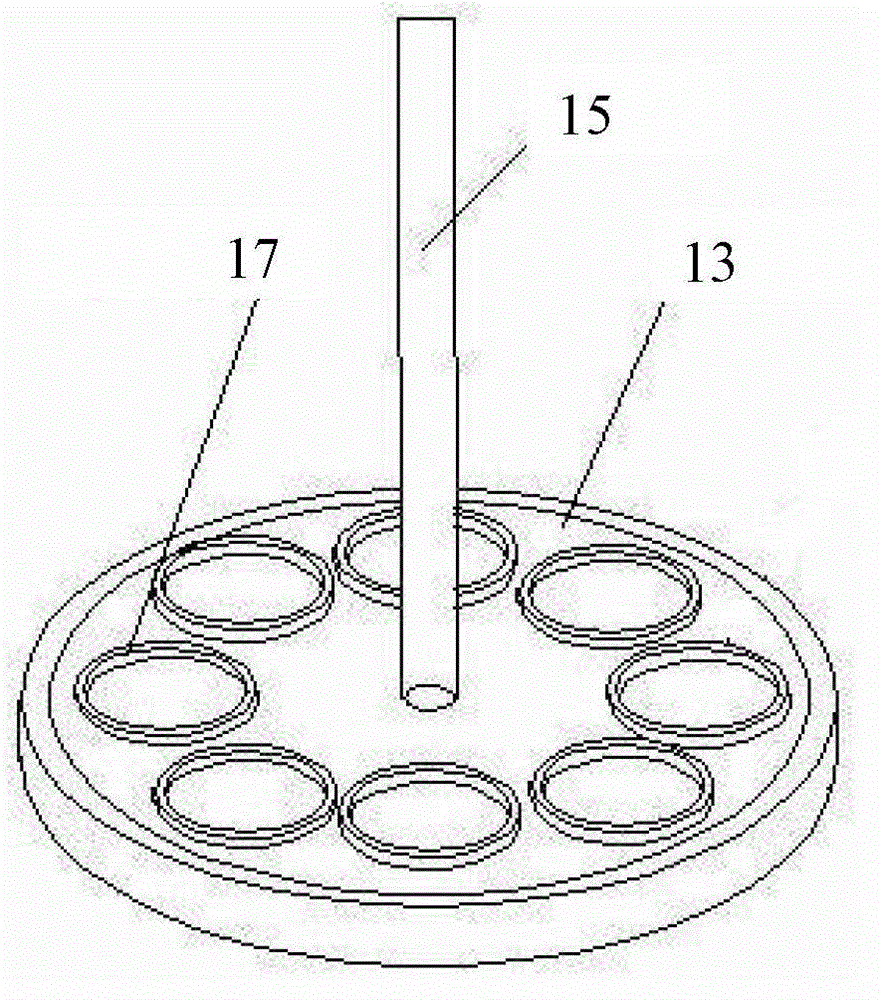

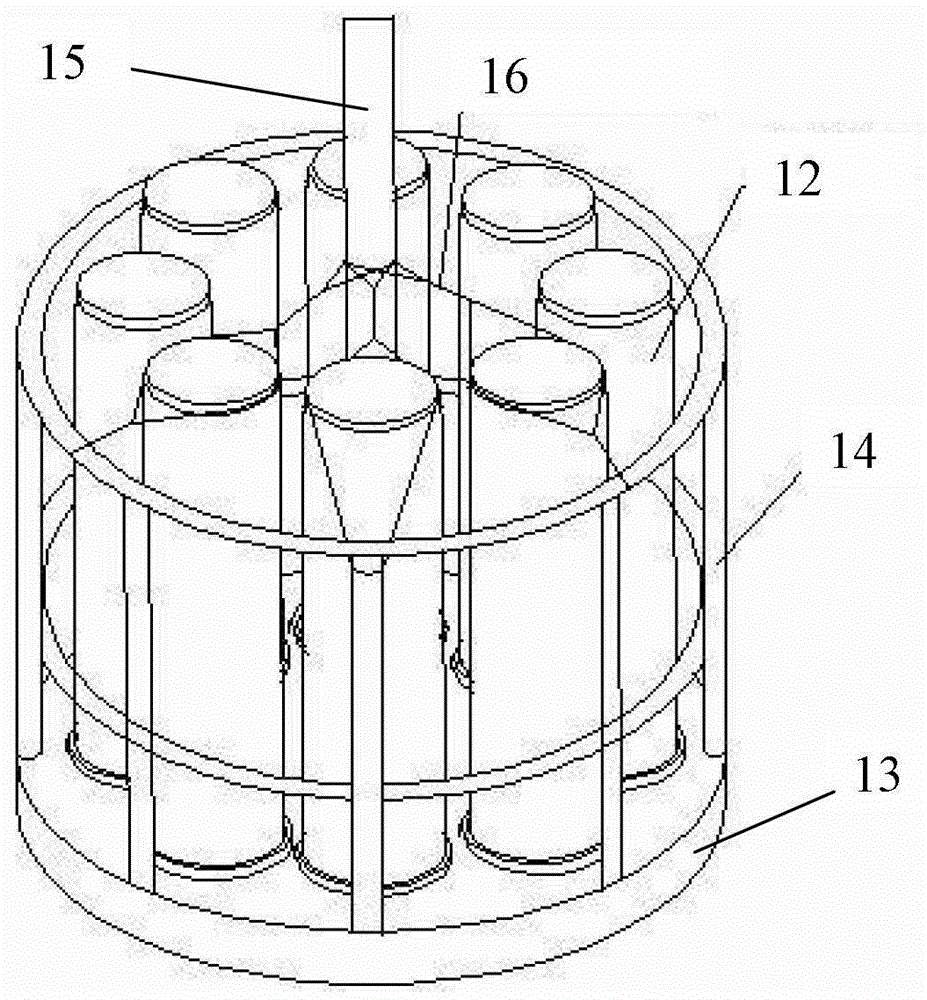

[0017] The processing device and method for preventing the deformation of the piston on the hydraulic cylinder for a breaker provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The same reference numerals are used for the same components as those in the prior art, and their descriptions are omitted.

[0018] like Figure 1-Figure 3 As shown, the processing device provided by the present invention that can prevent the deformation of the piston on the hydraulic cylinder for the breaker includes a chassis 13, a guardrail 14, a boom 15 and a positioning lead wire 16; wherein the chassis 13 is arranged horizontally, and the outside of the surface is evenly distributed with a plurality of The lower end of the guardrail 14 is arranged on the surface edge of the chassis 13; the hanger 15 is vertically arranged in the middle of the surface of the chassis 13; the positioning lead wire 16 is fixed betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com