Oxygen-rich redox furnace

A technology of reduction furnace and oxidation furnace, which is applied in the field of oxygen-enriched redox furnace, can solve the problems of inconvenient manufacturing, transportation and installation, and operation, and achieve the effects of easy maintenance, favorable processing and manufacturing, and sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

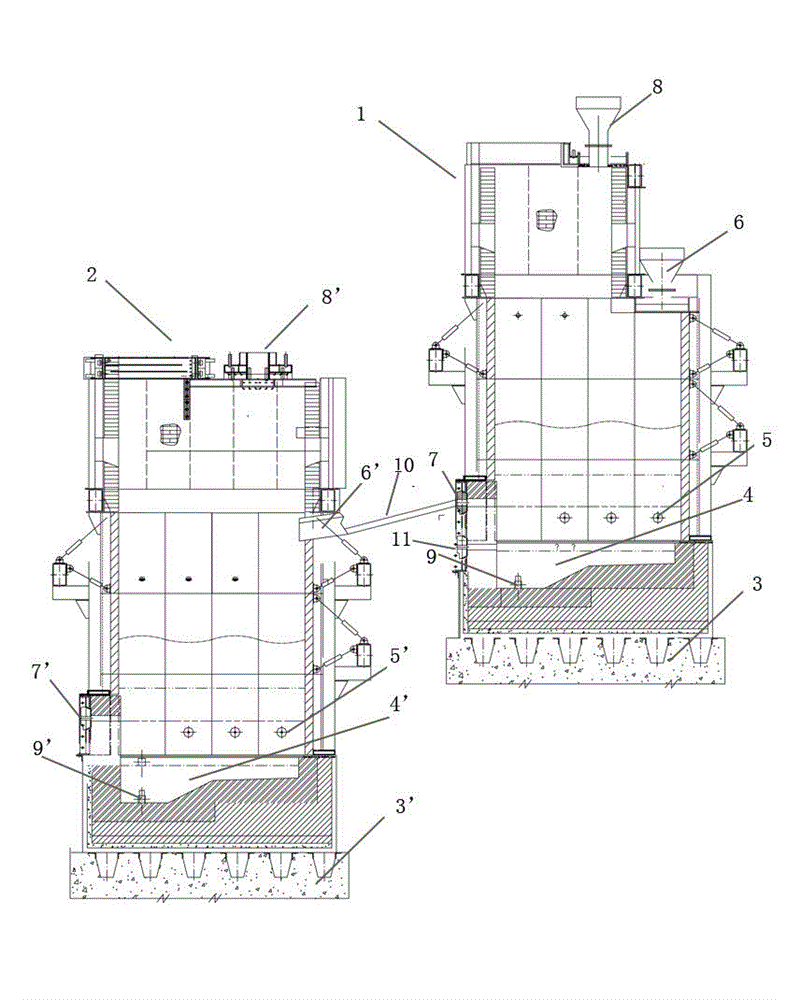

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation, but it does not limit the present invention.

[0013] An oxygen-enriched redox furnace, which is divided into two parts: an oxidation furnace body (1) and a reduction furnace body (2); Hearth (4, 4'), water jacket, tuyere (5, 5'), siphon inlet, feed inlet (6, 6'), discharge outlet (7, 7') and flue outlet (8, 8 '); the lowest part of the hearth (4, 4') in the two furnace bodies is also equipped with a safety port (9, 9'); the base surface of the furnace base (3, 3') of the oxidation furnace body (1) The layout position should be higher than the base surface of the furnace base (3, 3') of the reduction furnace body (2), between the discharge port (7) of the oxidation furnace body part and the feed port (6') of the reduction furnace body part A chute (10) is connected; a slag sticking port (11) is arranged on the outer surface of a part of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com