Section steel soil cement mixing pile with longitudinal displacement mechanism

A cement-soil mixing pile and section steel technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as complicated operation, time-consuming and laborious operation, low production efficiency, and inconvenient positioning of construction units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

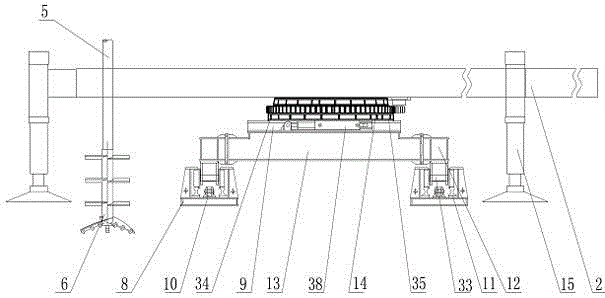

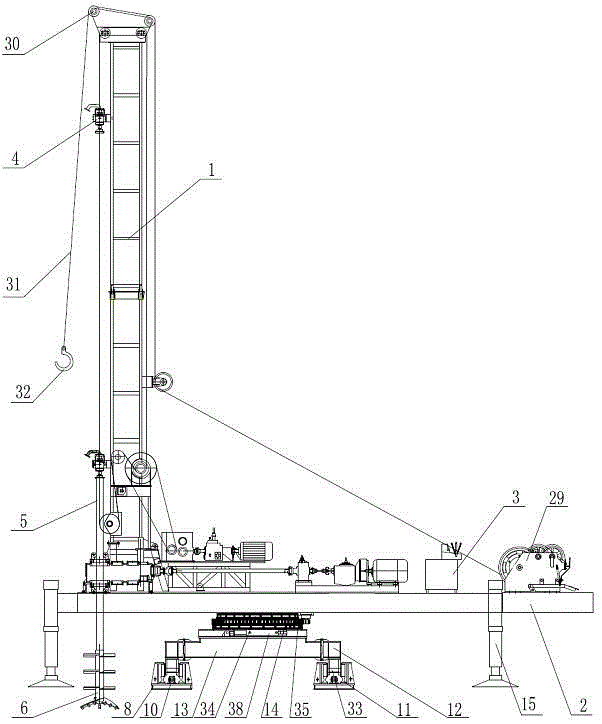

[0012] Below in conjunction with accompanying drawing, the implementation of technical scheme is described in further detail:

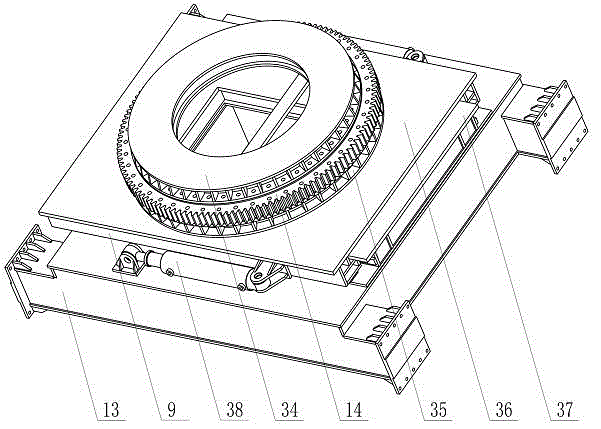

[0013] As shown in Figure 1, the steel cement-soil mixing pile machine with longitudinal movement mechanism of the present invention includes a tower frame 1, an upper chassis 2, a lower chassis 13, a hydraulic power system 3, a drill bit 6, a rotary mechanism 14, a longitudinal displacement mechanism 9, Lateral displacement mechanism 8.

[0014] The tower 1, the hydraulic power system 3 and the drill bit 6 are installed on the upper chassis 2, and the upper chassis 2 is fixedly connected to the upper connecting plate 34 on the upper part of the slewing mechanism 14, and the slewing mechanism 14 is fixedly connected to the longitudinal displacement mechanism through the lower connecting plate 35 9 upper part, the longitudinal displacement mechanism 9 is fixedly connected on the lower chassis 13 through the upper sliding box 36 and the lower sliding bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com